|

Title: |

1880 Article-Straight Line Engine Co., Horizontal Steam Engine |

|

Source: |

American Machinist, 22 May 1880, pg. 1 |

|

Insert Date: |

7/10/2015 9:56:13 PM |

The Straight Line Engine

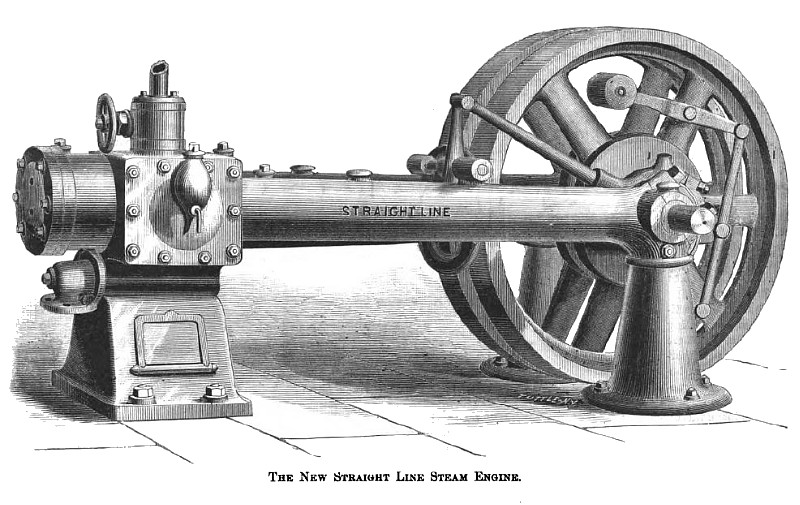

We present on this page a view of the new steam machine which the Straight Line Engine Company of Syracuse, N. Y., are preparing to put upon the market. It is designed by Prof. John E. Sweet, and is to be built under his superintendence. Although one of these engines was built for experimental purposes some ten years ago, and others with some modifications were since built, the present engine has been greatly simplified within the last year, and gives such unqualified satisfaction that a company has been formed for its manufacture.

The most noticeable feature of the engine —the one from which it takes its name—is the frame, which consists of two arms exactly alike, running straight from the cylinder to the main bearings. The entire engine rests upon three self-adjusting points of support; cannot by any possibility got out of line; requires no foundation except a small pier under the flywheel pedestals; and is thus practically self-contained.

A second peculiarity in this engine is its extreme simplicity. While it is a perfect automatic cut-off engine from ¾ stroke to zero there are no more working parts than in the most simple slide valve engine; governor, governor-belt and governor-valve being dispensed with.

The cylinder of the engine shown, which is 6"x 12" has an air space cast around it. The piston is very long, as light as possible, and fitted with spring rings. The piston-rod is fitted with or without packing. Those without are simply ground steel rods running through long reamed holes, steam tight. The usual sort of packing is furnished to those who prefer it. The cross-head is very long and heavy, and scraped to a perfect bearing on the slides. The cross-head pin, which turns in the cross-head instead of the connecting-rod, has two tempered steel, ground journals 1¾"x2¾''. They are adjustable for wear, and are oiled under motion through the upper slides, which are also adjustable for wear.

The connecting-rod is steel, with a crank-box 3^"x5" lined with best Babbitt metal. The crank joining the two fly-wheels is of steel ground to a perfect cylinder, as are the shafts, which have bearings 3"x9", and project to receive a pulley at either side of the machine. The fly-wheels also serve as pulleys if desired. The main journals have self-oiling rings, the waste oil from the outer end of the box being returned to the shaft, and. that from the inner end of one going to the crank, and of the other to the eccentric.

In addition to the self-oiling arrangements, every wearing surface can be oiled from a common oil can while running at the highest speed, as well as when at rest. The governor, as will be seen, is a single ball and a single spring controlling a single eccentric. The governor-ball is so located and loaded as to exactly balance the eccentric and its attachments. This requires a heavy ball, and that in its turn a heavy spring, which means a very powerful governor; and in addition to this, the pivots, subject to excessive pressure, are devised so as to work frictionless, requiring no oil. A heavy governor would ordinarily imply a costly governor; but in this case the parts are simple, and the weight serves as so much fly-wheel, paying for itself twice over.

The valve motion, though consisting of the ordinary eccentric-rod, rock-shaft and arm, is distinctive in this: that by a peculiar position of the upper rocker arm the valve motion is corrected, so that the lead remains constant and the cut-off practically alike at both ends of the cylinder, in whatever position the eccentric may be shifted by the governor. All parts of the valve motion are of steel, and the journals of about the size usually put on main connections in engines of this size.

The valve is a plain balance slide valve, having but one moving part; opens to let water out of the cylinder; is not affected by change of pressure or of temperature; can be refitted by an ordinary machinist, and is not affected by the wear due to its own weight. A recent improvement makes it as near perfect as present material and human skill are likely to attain.

It is the aim of the Straight Line Engine Company to furnish an engine to fill the gap between the Baxter and engines of that class on one hand, and the Corliss, Porter-Allen and Buckeye class on the other; that is, engines from 10 to 30 or 40 horse-power.

The working parts of the machines are to be in every way equal to the Porter-Allen work, which- is saying all that can be said about workmanship. There is probably no design of this class that has received more thought than the one under consideration, and some of the principles that have been considered may be mentioned. All strains (according to Mr. Porter) go in straight lines from power to resistance. This is the only machine in which the line of strain is in the center of the frame. A frame resting upon three points of support can never be strained, while an engine depending upon a foundation for its alignment implies an absolutely unyielding foundation and careful setting, that is expensive; or a yielding foundation, constant distortion, and endless trouble.

A large portion of the power given off by the steam must be absorbed by the reciprocating parts and fly-wheels.

In this design the weight in the reciprocating parts is put in the crosshead instead of the piston, on the theory that the wear is less detrimental. The heavy counter-weight is equal on each side of the strain, and the centrifugal force of the counter weight is never enough to raise the fly-wheels out of their bearings. The whole force of the steam is given direct to the fly-wheels without being transmitted to the main shaft.

It is the intention of the builders to furnish an engine that shall require no attendance, except that of turning on and off steam, and keeping the wearing surfaces oiled; an engine that can be run at moderate or the highest speed, that will require the least possible amount of foundation, that can be taken down, moved, and set up in the shortest possible time, and give the least possible trouble to the purchaser. |

|

1880 Straight Line Engine Co., Horizontal Steam Engine

1880 Straight Line Engine Co., Horizontal Steam Engine

|

|