|

Title: |

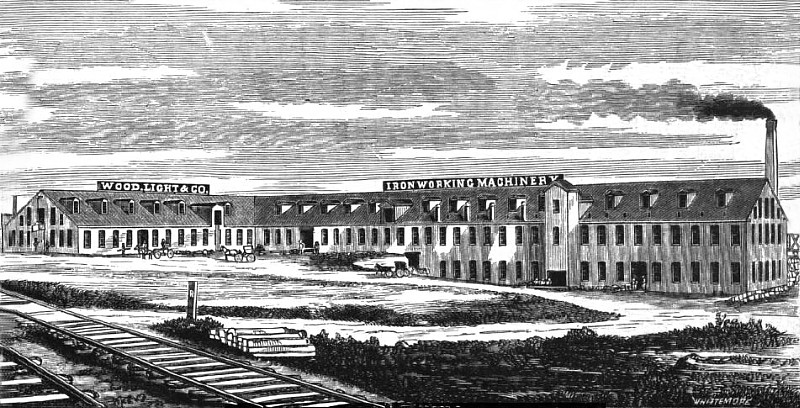

1872 Article-Wood & Light Machine Co., Factory View |

|

Source: |

The Great Industries of the United States, 1872, pg. 687 |

|

Insert Date: |

11/23/2015 7:44:45 PM |

Among the numerous firms engaged in iron working machinery that of Messrs. Wood, Light & Co., of Worcester, Massachusetts, may be justly selected as especially representative. Not only does this firm hold this position from the importance of their business, and its deserved reputation, but also from the fact that the members composing it have, by their various inventions, done much towards extending the application of machinery to the working in iron, and opening new fields for the use of iron in the arts. Being themselves practical mechanics, and having a knowledge, from experience, of what was needed in the application of machinery to the working of iron, the members of this firm have been enabled to devote their inventive talents to supplying the wants universally felt for improvements in certain directions, while the reception their inventions have met, is a proof of the general existence of the want they have supplied.

At their establishment in Worcester, Massachusetts, they have the appliances for making any and every kind of machinery, though their business is chiefly confined to certain specialties, which they control, as they own the patents. A description of some of these will show the character of the modern appliances for working iron.

First we will mention an improved bolt cutter, the patent right to which they control. This simply constructed but ingenious machine is a great improvement upon the methods formerly in use. Its chief features are four movable dies placed in an adjustable holder, and, by a simple and durable arrangement, opened and closed by the automatic action of the machine, or by hand if necessary. For all square-headed bolts it has a holder into which a bolt can be put, or from which it can be removed, in an instant, without the use of a screw or wrench. When the bolt is placed in the holder and moved forward until it meets the dies, a lever on the front of the machine is pressed down, the bolt enters the holder and is carried on by the action of the machine until the threads are cut into the desired length. Then an adjustable rod lifts a latch, and a hand falls into a notch and holds a cam, while the dies revolve and are instantly opened, as a cam on the driving gear presses a rod against the bolt holder, and the bolt is released and thrown out of the dies, which are then ready for repeating the process upon another bolt.

The dies and die-holders are all made to fit a steel templet, and are drilled and tapped in a machine, in every respect exactly alike. The holders in every machine are so made that several sets of dies will work equally well in them, so that the operator can supply himself with dies of any required size from the manufacturer, at a cheaper rate than they could be made by anyone else not having the same facilities.

In this machine the size of the thread on the bolts may be instantaneously adjusted to any variation in the nut. The machine is entirely automatic, requiring only to be " fed," when it performs its work with more accuracy than could be done by hand. When the dies of the machine become worn and dulled, they may be annealed and re-set in the machine, and re-cut in place, the ingenious device by which the dies are made to accommodate themselves to the different sizes of the bolts, acting now to adjust the dies themselves, made shorter by the process of re-cutting, so that in relation to each other the aperture between them shall be no longer than it was before. In this way the difficulty attending the wearing away of the dies, and the shortening of the die plates by repeated re-cutting, is overcome, and the dies are made useful until their substance is worn away.

Another machine manufactured by Messrs. Wood, Light & Co. is a double milling machine, which was recently invented and patented by Mr. Wood. This machine is already in great demand among manufacturers, since it not only accomplishes twice as much as a single milling machine, but performs it with greater accuracy. It is found to be of especial importance in the milling of gun work, and in the manufacture of sewing machines, besides a thousand other branches of industry to which its rapidity of work and convenience make it peculiarly applicable.

Another invention by Mr. Wood, and which is manufactured by the firm, is an automatic shafting lathe. This lathe is noticeable not only for the principle upon which it is constructed, but also for the amount of work it will do, as it will turn thirty feet of two-inch shafting an hour, which is fully four times as much as any ordinary lathe can do.

The great difficulty in turning iron rapidly arises from the heat generated by friction in the iron worked, and also in the cutting tool, the temper of which is destroyed if the work is driven fast enough to make its heat excessive. To overcome this difficulty, turners in iron have been accustomed to use water for the purpose of keeping the cutting tool cool, allowing it to drip continually upon the iron.

This invention, however, for the purpose of avoiding this difficulty, is much more effective. It consists in making the bed of the lathe, through its entire length, a trough, or open tank, which is kept nearly filled with water impregnated with soda, and which is constantly distributed over the shafting by pumps worked by the same power that works the cutting tools. Of these tools, three are kept in operation at the same time, being placed in line, the first cutting off the "scaling chip," the second removing the next layer of "chips," and the third finishing the work.

This lathe is also so constructed that the soda water is never dashed or sprinkled over the sides of the tank, though it is pumped continually upon the work, so that the floor under the tank is kept constantly perfectly dry. This practical consideration for the health and comfort of the workmen is well worthy of notice.

Another invention to use with this consists of a "cutting-off and centering machine." This ingenious piece of mechanism cuts off and centres shafting in order to prepare it for turning. This has heretofore been a tedious operation, which has frequently been performed unsuccessfully, but by this machine it is accomplished regularly, easily, and in a scientific manner. The machine consists of a hollow cylinder, or "spindle," made to revolve on its bearings, and having at each end a "scroll chuck," by which the shafting, or work to be cut and centered, is confined centrally with perfect precision. The shafting is then cut off at exact right angles to its length, when by a most ingenious combination of gearing exactly graduated to the work to be done, the shafting is centered and counter-sunk ready for turning. The whole of this work — cutting, centering, and counter-sinking — requiring by this machine not a sixth part of the time consumed in accomplishing the same results by the old methods, while also by this machine the entire series of operations are accurately performed by unskilled labor; any one who can turn a crank being able to put the shafting in proper position, and the setting of the centring tool requiring only a simple motion of the hand.

In the process of planing iron, which has come to be so generally used, great improvements have been introduced by this firm. The largest planing machine in the United States is in the Navy Yard at Charlestown, Massachusetts, in which a piece of iron forty-two feet long by twenty-five wide can be planed. The iron planer is generally a machine consisting of a long bed-piece supported by legs, upon which a movable table rests, and which is worked by cog-wheel machinery underneath the table. Above the table, and fixed to the bed-piece, rises what is known as an "upright," on which is arranged a cross-bar, so adjusted to the upright as to be able to move up and down, accommodating itself to the thickness of the iron to be planed. The iron is placed upon the table, and this being moved as required along the bed-plate, brings the iron under the knife, or planer, which is affixed to the cross-bar. Planers of this kind are known as rack-feed planers, in contradistinction to the old chain-feed planers, both names being derived from the appliance by which the table is moved, either with cogs or with a chain.

An improved planer manufactured by Messrs. Wood, Light & Co. is known as the Warren Patent Shaping Machine, and is the invention of Mr. William H. Warren, in the employ of this firm, and was patented in 1868, and again in 1871. Its manufacture already forms an important part of the production of this vast industrial establishment.

In the old style of planers many difficulties remained unsurmounted. They were unable to plane, without great trouble, many forms of iron; or, if a long piece of iron was to be planed, and was laid upon the table cross-wise, that portion of it which projected over the table needed to be propped up with care. Otherwise there was constant danger lest it should tip up the table, raising it from the grooves in which it slides, and thus disarrange the planer. It was also almost impossible with the old style of planer to plane the iron regularly. Another important objection against the old form is, that it did not sufficiently economize time, since one half of the time spent in the operation was lost while the table was returning to its original position after having passed the iron under the tool.

This was particularly the case when large pieces were to be planed. Besides, too, the old planers were adjusted to only one rate of speed, and could not plane small pieces of iron proportionally faster than large ones. This will appear more forcibly when it is considered that in planing a short piece the machine has to run back oftener than in planing a long one, each return being so much loss of time.

In undertaking to practically obviate these objections, a machine is produced in which a piece of iron of any size, or any form or shape, whether circular, angular, or what not, can be planed. His improved planer consists of a bed-piece resting upon legs, upon which is fixed a "shoe," so called, in which is adjusted a "sliding ram," which holds at its head the cutting tool. This ram is made to move forward by eccentric machinery, of the crank-motion kind, carrying the tool over the work to be planed, instead of the work being carried under the stationary cutting tool, as in the old form. By this improved method the desirable end is gained of causing the cutting tool, after it has accomplished its work, or gone as far as it can reach, to return suddenly to its original position, thus saving about forty per cent, of the time heretofore occupied in planing a given piece of iron.

The inventor has also added a device by which the stroke of the cutting tool can be made long or short, or light or heavy, at the option of the operator who guides it, and this while the machine is in operation, no time being thus lost in adjusting the tool. By this improvement, any portion of a piece of iron requiring to be planed can be subjected to the action of the tool, while another portion of the same piece may be left untouched. The machine is also automatic, and may be left to do any regular piece of work itself, without any fear of its making a mistake.

To the side of the bed-plate is fixed a sliding table upon which the piece of iron to be planed is placed, and which gradually moves by regulated machinery so as to push the piece to be planed sidewise under the cutting tool. By a device of cogs and a table crank, invented by him, this sliding table is rapidly put back to its starting-point, after having once run to its end along the bed-piece, thus again saving a large proportion of time.

The machine is also supplied with a most ingenious, though seemingly complicated device, by which what is called the "down feed" is effected automatically, thus saving the time of the workman and securing greater evenness in the work. This "down feeder," or "angular feeder," as it is also called, is automatic at any point or angle. The side sliding table, on which the work is placed, is moved up and down, to suit the work to be planed, by a perpendicular screw operating in a novel way, by which much time is saved to the workman.

The machine is, in short, one of the most noticeable triumphs of invention in the department of constructive machinery, and being controlled by Messrs. Wood, Light & Co., gives them great industrial advantages. Mr. Warren has also patented improvements upon the slotting machine manufactured by this firm, by which " a positive, automatic, total relief of the cutting tool when on its return" is secured, thus preventing the wearing of the tool and the roughening of the work, while at the same time making the positive cutting of the tool more accurate and smooth than by any former process.

These improvements accomplish a saving in the operation of slotting machines estimated at fully forty per cent. With these improvements, the position of the ram and the length of the stroke are both adjusted while the machine is in operation, whereas to accomplish either of these things formerly required the stopping of the machine, and a consequent loss of time. This slotting machine is a most convenient tool to have in a machine shop, it being adapted not only to slotting proper, but to planing at any angle, or circularly, or in any other form, as, for example, the strap for connecting rods, which presents in its surface curves, circles, planes, right angles, inner and outer planes and edges. |

|

1872 Wood & Light Machine Co., Factory View

1872 Wood & Light Machine Co., Factory View

|

|