|

Title: |

1921 Article-Graham Mfg. Co., Ring Type Grinding Machine |

|

Source: |

Machinery, V28, Oct 1921, pg. 152 |

|

Insert Date: |

6/18/2016 12:42:45 PM |

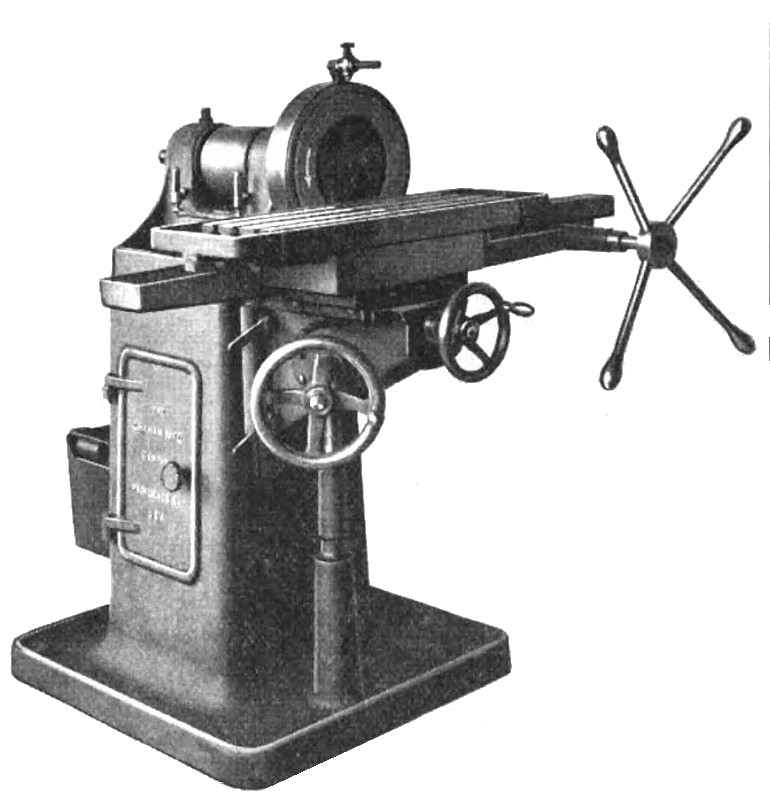

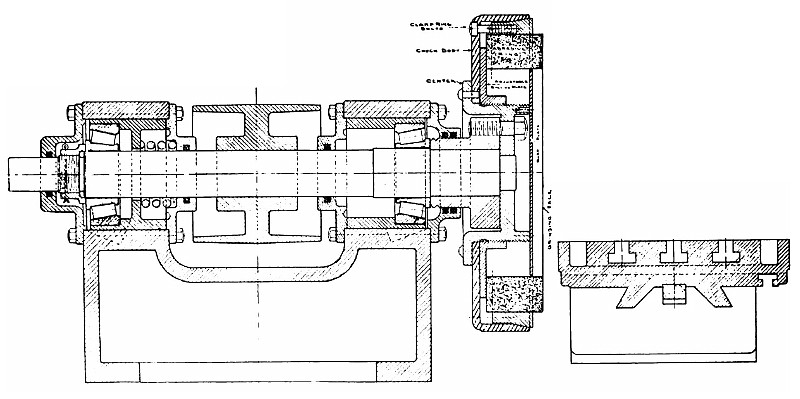

The knee-type ring-wheel grinding machine illustrated in Fig. 1 was recently developed by the Graham Mfg. Co., 71 Willard Ave., Providence. R. I. The abrasive wheel has an outside diameter of 12 inches and a hole 7 inches in diameter, so that the face is 2½ inches wide. The thickness of the wheel when new is 3 inches, and it can be worn to a thickness of about ½ inch. The wheel is held in place by a pressed-steel holder, manufactured by the same concern, which was described in May, 1909, MACHINERY. The construction of this holder can be seen by reference to Fig. 2, which shows a sectional view of the wheel-head. The ring wheel is clamped in this holder by means of a cone shaped ring that is drawn into an internal tapered surface in the body. An adjustable flange which screws on the hub of the holder is employed to advance the wheel as the latter becomes worn, and it is an easy matter to remove a worn ring.

After the wheel is in place it can be easily trued up and the cutting face reduced to any desired width. A holder for commercial truing devices is supplied, which is fastened to the table. The machine may be driven by a belt from a countershaft as provided for on the machine illustrated, or it may be driven by a motor, mounted on a bracket at the back of the machine and attached to the rear end of the wheel spindle by means of a flexible coupling. The machine may also be driven by belt from a motor mounted on a bracket on the right-hand side of the column, or one placed inside the column and belted upward. A fifth driving method is by means of a motor built into the head.

The column has cast ledges on the inside to provide for shelves; however, the space may be used for a starting box. Water is supplied to the work by means of a No. 2 B. & S. centrifugal pump, fastened to a tank at the rear of the machine, the water being applied to the work through a nozzle fastened to universal pipe joints. The head is cast separately and is provided with bushings for holding the outer races of the Timken roller bearings with which the spindle is equipped. In order to reduce end play to a minimum, the rear bushing is a close sliding fit in the head and is pushed, by means of a coil spring, in the proper direction to automatically take up all end motion and wear. Further adjustment is attained by means of a castellated nut and cotter-pin. The spindle is made of tool steel and is provided at the front end with a collar shrunk on and machined to accommodate the ring-wheel holder. Felt-packed dust collars protect all running parts on the head, and glass oilers indicate the amount of lubricant in the bearings.

The knee is of box construction, and is adjusted by an elevating hand-wheel set at an angle. A water trough is machined and fitted to the knee. The table block rests on the knee and is gibbed. It is fitted with an adjustable nut for the cross-feed shaft. This nut may be indexed in increments of 0.001 inch and serves to regulate the depth of cut. The table is fed past the wheel by means of a pinion and rack operated by the spider wheel at the right end. The top surface of the table has standard T-slots in it. Sufficient water guards are furnished to prevent the operator from becoming splashed. These guards were removed at the time the photograph reproduced in Fig. 1 was taken, in order that the construction of the machine could be more readily observed. Some of the specifications of this grinding machine are as follows: Height from floor to center of spindle, 42 inches; working surface of table, 24 by 10 inches; maximum travel of table, 16 inches; vertical movement of table, 7 inches; speed of machine, when driven by standard motor, 1780 revolutions per minute; and weight of machine, approximately 2000 pounds. |

|

1921 Graham Mfg. Co., Ring Type Grinding Machine

1921 Graham Mfg. Co., Ring Type Grinding Machine

1921 Graham Mfg. Co., Ring Type Grinding Machine (Sectional View of Grinding Spindle)

1921 Graham Mfg. Co., Ring Type Grinding Machine (Sectional View of Grinding Spindle)

|

|