|

Title: |

1874 Article-Buckeye Engine Co., Horizontal Steam Engine |

|

Source: |

Engineer, Architech & Surveyor, Mechanical Supplement to #7, 15 Oct 1874, pg. 119 |

|

Insert Date: |

6/27/2016 7:32:09 PM |

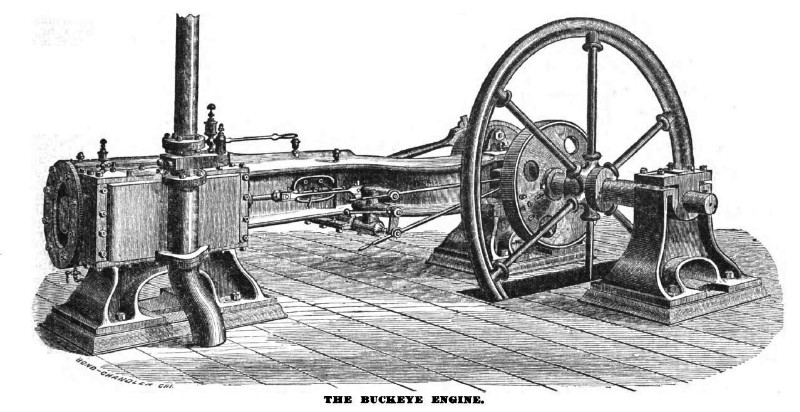

The steam is admitted to the cylinder through the slide valve instead of around it. It enters the valves through circular openings in its back, and is admitted from thence to the cylinder through two ports, which are alternately brought to coincide with the cylinder ports. The exhaust takes place at the ends of the valve, instead of through a cavity under it. The steam, when released, passes directly through the ends of the steam chest, and through ample passages into the exhaust pipe seen in the cut passing downwards. The openings in the back of the valve, besides admitting steam to its interior, also serve to furnish the pressure which holds it to its seat, and, as they are made of just sufficient area to accomplish this purpose, the valve is as nearly balanced as is practicable with any form of valve in use. The cut-off valves are contained inside of the main valve, and alternately cover the ports from which the steam passes into the cylinder. They are actuated by an eccentric on the main shaft, the position of which is under the control of the centrifugal force of the pivoted weights contained in the circular or pulley-shaped case seen on the engine shaft. The main valve is operated by a fixed eccentric placed alongside the adjustable one. By means of the novel compound rock-shaft arrangement (shown in the lower cut) through which motion is transmitted from the eccentrics to the valves, the movement of the main valve is prevented from distorting or in any way disturbing the movement of the cut-off valves inside of it, the cut-off taking place at any point from zero to half stroke, as may be determined by the load on the engine, or the pressure of steam in the boiler. The engine is very closely governed, and uses steam with the highest economy; consequently it is particularly adapted to flouring mills, as well as to all purposes where a uniform speed is desirable, and to locations where fuel is expensive.

The Indicator diagrams shown were excellent; cut-off at 1/6th stroke with 60 lbs. for initial, and atmospheric for final pressure, and average piston pressure of 21 lbs., boiler pressure, 61 lbs., very small amount of compression or back pressure shown, and remarkably uniform expansion from the cut-off to end of stroke. About as much clearance is required in the ports as in the ordinary slide valve engine, and the economy in fuel is 1/3 more than can be obtained with the best form of throttling engine. |

|

1874 Buckeye Engine Co., Horizontal Steam Engine

1874 Buckeye Engine Co., Horizontal Steam Engine

|

|