|

Title: |

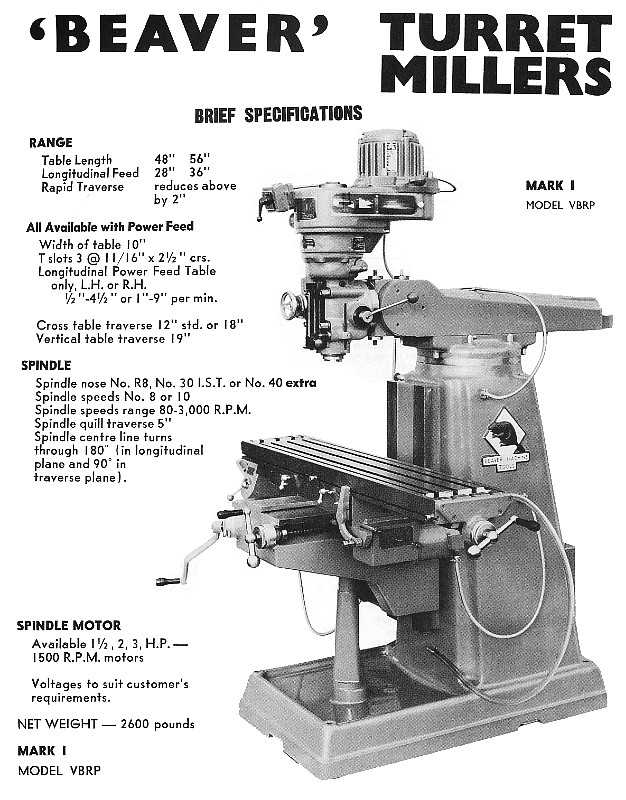

1967 Ad-Balding Engineering, Ltd., Beaver Vertical Turret Miller, Mark I |

|

Source: |

Brown Machinery Co. Catalog, 1967, pg. 2 |

|

Insert Date: |

7/7/2016 8:10:17 PM |

‘BEAVER’ SWIVELLING TURRET MODEL ‘VBRP’ MILLING MACHINE MARK-I

‘RP’ MILLING HEAD—This all-angle milling head is a complete self-contained unit. Eight spindle speeds are provided, four on the high speed range and four on the low speed range, operated by a quick action single lever.

The drive is taken from a machine tool balanced motor by vee belt to a four step idler pulley. This pulley is mounted on two precision ball-bearings housed in the top aluminum bracket. The motor is hinged so that the belt can be easily changed and adjusted for tensioning. The drive is then taken from the idler pulley through a powerful precision cut spur back gearing. Ail the pulleys and gears are dynamically balanced electrically to ensure a vibration free head. A six-spline driving sleeve is mounted on the upper housing on two precision ball-bearings. All the load from the back gearing is taken on these bearings thus freeing the spindle from any stress. The spline -sleeve drives the main spindle which is mounted in the sliding quill as shown.

The spindle is mounted on three very high precision bearings. A matched pair of preloaded angular contact ball bearings are positioned in the nose and the other ball journal bearing positioned in the upper end of the quill. The large diameter hard chrome plated quill is precision ground. The quill housing is carefully fine bored and honed to a very high standard of ?nish and roundness and close tolerance fit.

The spindle travel is 5” with an adjustable depth stop on the side of the housing. A single hand lever gives rapid quill movement via a pinion and rack, very useful for plunge cutting, drilling and reaming etc. A hand wheel complete with a micrometer collar gives fine feed through a worm and worm wheel, very useful for fine boring, etc. The quill has three rates of power down feed per spindle speed. Any depth setting can be made and is automatically knocked off. An important feature is the self-reacting spindle action.

RAM AND TURRET—The prismatic over-arm is securely clamped to the turret with two quick action clamping nuts. The ram movement is actuated by rack and pinion and revolves with the turret 360°.

COLUMN AND KNEE—The main column and base of the machine is a one-piece casting of very rugged construction. It is honeycomb webbed throughout to evenly distribute the cutting stresses and absorb all the vibration. The base of the column incorporates a reservoir for the cutting oil. The suds pump is mounted within the column and is a completely self-contained unit. All square ways of generous bearing proportions are utilized throughout the machine.

The knee is of extremely wide proportions for this size of machine, thereby ensuring stability of cut over large areas, particularly when fly cutting. The narrow type square saddle guide bearing is utilized together with a full length key for maintaining accuracy. The elevation screw of the knee has a precision Acme thread turning on ball thrust bearings thence to high precision machine cut bevel gears.

SADDLE—The saddle is a very rugged casting which is virtually machined all over, thereby retaining its original machined precision. Long bearing support is given to the table on the ‘V’ ground dovetail ways, approximately 22". The feed screw for the cross feed is1” dia. made from high carbon steel and precision produced for pitch and accuracy. Very accurate movement is obtained through the back lash eliminating double nuts.

A bail thrust race is incorporated to give fine feel. The cross travel is 12”. It should be noted that this screw has been carefully tucked away underneath the right hand knee way to ensure that it is kept free from falling chips, dirt etc.

TABLE—The table can be supplied in any one of the four sizes specified on page four. It will be noted that the table has false ends ensuring that the cutting oil is correctly returned to the sump within the base. Two suds trap ways are also incorporated in the design and the three main ‘T’ slots have been carried through to the ends of the table, ensuring that when necessary the complete working surface of the table. as specifies can be utilized at any time.

The drive to this table is by hand, or power through the gearbox. The drive is taken through a precision steel screw through double nuts which act as back lash eliminator enabling the operator to feed cuts in either direction. Adjustment to this back-lash eliminator is very easily made in situ.

Large easily read micrometer dials, "friction loaded" are attached to each end of the table and ball handles with rotating handles are fitted at each end for easy operation so that the operator may work right or left hand as desired.

The ‘T’ slot in front of the table has adjustable stops which can be adjusted to give extreme accuracy for length of cut. They also operate as automatic knock-offs for the power feed gearbox.

GEARBOX—This electrically driven gearbox has been designed for the customer who feels that a long power traverse is essential. The whole unit is very neat and light, driven by a fractional H.P. motor which is totally enclosed.

The gearbox can be supplied in two ranges of feeds, ½”-4½” or 1”-9” per min. The method of change is by pick-off gearing. The drive is taken direct from the motor which has a worm attached to its shaft engaging with a worm wheel. Various reductions are then achieved through spur gears to the table feed screw. The right hand and left hand traverse is instantly obtainable through the selection lever. All gears within this gearbox are running in an oil sump system. |

|

1967 Balding Engineering, Ltd., Beaver Vertical Turret Miller, Mark I

1967 Balding Engineering, Ltd., Beaver Vertical Turret Miller, Mark I

|

|