|

Title: |

1826 Article-Mason & Tyler, Slide Rest |

|

Source: |

Journal of the Franklin Institute, V1, Aug 1826, pg. 104-105 & Plate 44 |

|

Insert Date: |

11/30/2016 1:50:00 PM |

A description of the American Slide rest, as made by Messrs. Mason & Tyler, of Philadelphia; with the improvements of other machinists

Where perfect accuracy is required, in turning cylinders, cones, or flat surfaces, the slide rest, is an appendage to a lathe, which is almost indispensable. Those made by Maudslay, and by Holtzapffel and Dyerlein, in London, are justly esteemed, both for their beauty and the accuracy of their workmanship: and it is no small praise to aver that those made in this city by Messrs. Mason & Tyler, are equal in both respects, and reflect the highest credit upon those artists. The slide rest is applicable to other purposes than those above mentioned, particularly to the cutting of accurate screws, on work in the lathe. This application will hereafter be described.

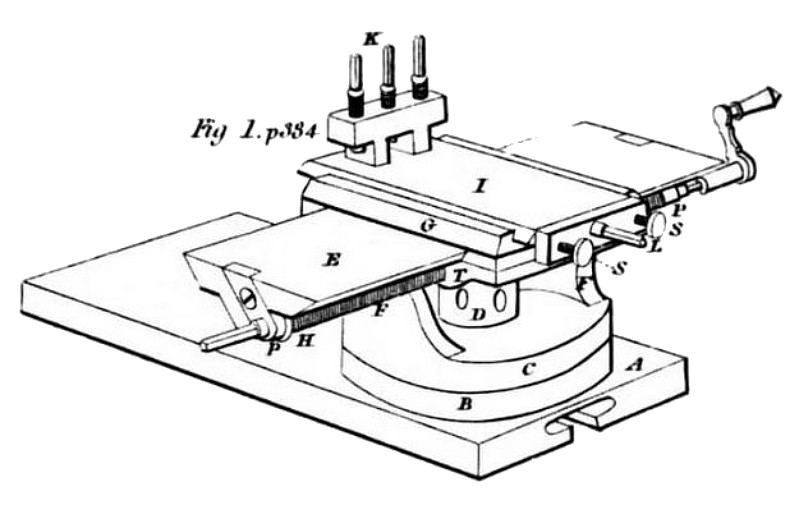

A, fig. l. (see plate) represents a piece of metal grooved underneath, to receive the holdfast, as in the common rest, having a circular projection at B, made flat at the top, forming a bed on which the circular base C rests, and is held fast to it by the screw-bolt D, in the centre of the base.

E, the main-bar connected to the base C by the supports F F, made perfectly flat on its upper surface, having the edges parallel and beveled under, to fit the dove-tail groove, in the lower side of the main slide G; in the top of the main slide is the dove-tail groove, crossing the lower groove at right angles, which receives the cross slide I, on which the cutting tool is placed, and may be held by either of the screws, K.

The screw H, which moves the' main slide is supported underneath the edge of the main bar by a collar, P, at each end, to protect it from chips, &c. and works in a semicircular nut, T, which is attached to the main slide. The collars P P being smaller than the screw, permit the nut to pass over them, and the slide to be taken off at pleasure; L, a screw by which the cross slide is moved ; it passes through the collar M, on the end of the slide T, and works in a nut formed in the bottom of the groove. At each end of the collar piece M, is a stop screw S, used in turning grooves of uniform depth, &c.

From the foregoing description, it is obvious that the cutting tool may be moved in the direction of either slide, or in lines at right angles to each other.

For turning cones, cylinders, concave surfaces, facing wheels, &c. the rest may be turned around the centre pin D, by which it is screwed down to the bed.

It is believed that this improved rest combines all the advantages of other instruments of the kind, with greater strength and firmness; and it is adapted to the common lathe. |

|

1826 Mason & Tyler, Slide Rest

1826 Mason & Tyler, Slide Rest

|

|