|

Title: |

1872 Article-Waters Governor Co., Steam Engine Governor |

|

Source: |

The Industrial Monthly, V1, Jan 1872, pg. 5 |

|

Insert Date: |

3/25/2017 8:44:04 PM |

Steam Engine Governors

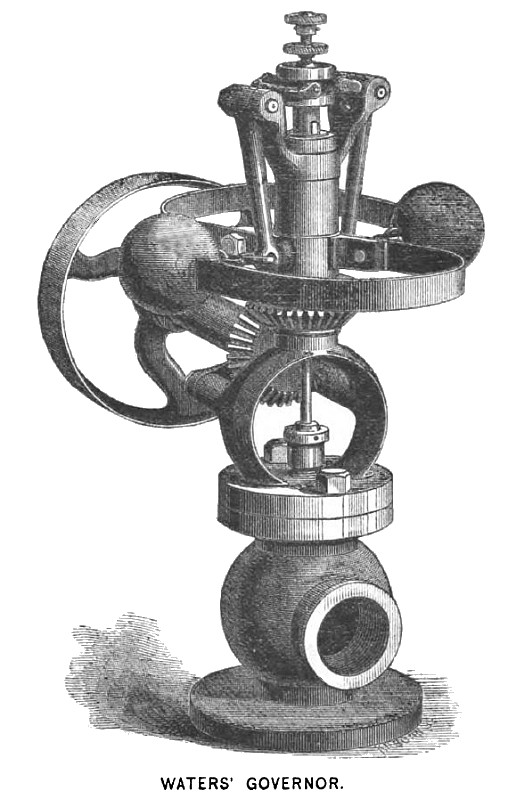

In devices for regulating the speed of steam-engines, we find that the principle of centrifugal force has received the most attention, and been practically applied oftener than any other. Ever since the days of Watt. who first applied a governor to the steam-engine, the ingenuity of engineers has been tasked to make the governor sensitive without impairing its steadiness. An English authority stated, some few years since, that the governor had received no improvement since the days of Watt; but, since that statement was made, there have been several devices brought to notice, each inventor claiming an improvement on the governor as first applied. The governors constructed by Corliss, Porter, Judson, Huntoon, with some others which are extensively used, are doubtless familiar to many of our readers. We here give a description and a representation of another recent device for a governor as invented by C. Waters, of Boston, Mass.

This governor differs essentially in construction from others. The shaft or spindle is stationary, and the body of the governor revolves upon it. This brings the gears on the outside of the frame, which admits of finish and ease in cleaning. To this body, or barrel, are secured two V-shaped springs, of thin, flat steel, to one end of which the balls—which are lighter than usual—are secured. It is easy to see that there can be no friction caused in revolving the balls by this arrangement, and the springs supply the force which gravity does in other cases; the balls always revolving in the same plane. Motion is imported from the balls to the arms through small steel hooks, and is communicated from the arms directly to the valve. The arms are forked on their short ends to receive a square bar of hardened steel, which turns freely on a pin through its centre, and travels in a grooved composition collar, which slides freely up and down in the stationary centre or bearing. This collar is prevented from revolving by a key, and is bored through the centre to receive the valve-stem, which is furnished with a screw on its upper end. and a milled head and check-nut. By screwing this up or down, the speed is instantly changed. It is claimed that, by this arrangement, the speed of the engine may be varied from thirty to fifty percent, which is a great convenience: that the valve is perfectly balanced, and is protected from the current of steam as it enters the chamber, thus causing it to wear equally, as it is not forced off to one side as in common valves; that no change, however sudden or violent, is too quick for these governors; and that the entire load may be thrown off the engine with perfect safety, under any pressure; at the same time, it is capable of changes so delicate that it requires the closest observation to detect them. They run perfectly steady unless the engine is very heavily loaded, when, if the belt be tight, they will show every admission of steam to the cylinder. They run very light, and do not require an extraordinary high speed. The bearings are made of Babbitt’s metal, and the whole machine is constructed in the most durable and workmanlike manner.

US Patent: 110,703

http://datamp.org/patents/displayPatent.php?number=110703&typeCode=0 |

|

1872 Waters Governor Co., Steam Engine Governor

1872 Waters Governor Co., Steam Engine Governor

|

|