|

Title: |

1851 Article-F. & T. Townsend Foundry, Beardslee's Elastic Cutter |

|

Source: |

Scientific American, 11 Oct, 1851, pg. 20 |

|

Insert Date: |

4/9/2017 8:15:11 PM |

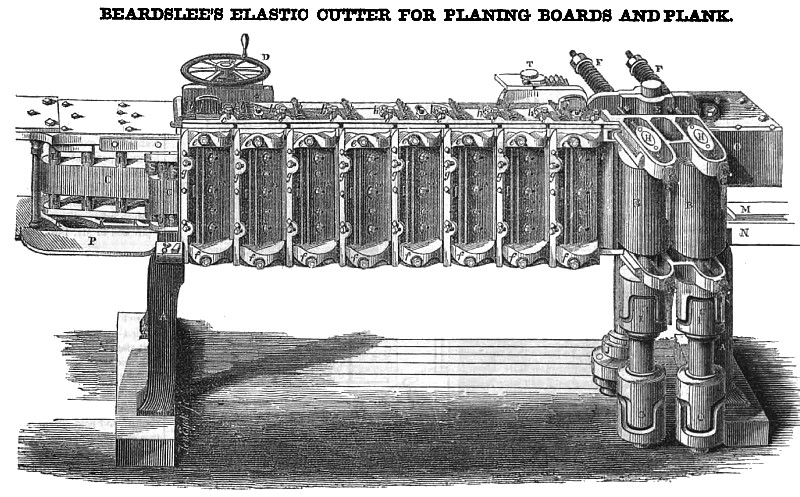

A A are the legs which support the machine; B B are the feeding rollers; C C are sectional plates that form the movable bed; D is the hand wheel which operates the raising screws; E is abox cap of the main driving shaft; F F are springs attached to the feed rollers; G G are handle nuts to adjust the rollers; H H are the roller shafts; I I are universal joints which connect the rollers with the lower gear; J is the coupling which unites the main shaft with the lower gearing; K K K are concentric grooves which guide the plates at each end of the machine; L L L L L L are racks in the plates; M N is the feeding table; O is an iron shield to the plates at the feeding end; P is a guide at the tail end of the machine ; Q is a lug of the main frame to attach it to the legs; S S S S are cogs that work in the racks; a a a a a a a are the knives and caps; b b b b b b b are springs which hold the heel of the stocks attached to the hinged bars ; c c c c c c care set nuts to the socket bolts, which adjust each knife and stock separately; 2 c e as c c c are nuts to t bolts which fasten the stock to the hinged rs ; f f f f f f f f are knife stocks; g g g g g g g g are steel bars forming throats bolted to the stocks ; h h h h h h h h are nuts to adjust the socket bolts; i is a fixed bar to the head knife ; j j are raising screw nuts attached to the side plates.

Letters Patent were granted by the United States, on the 20th of May last, to George W. Beardslee, of the city of Albany, N. Y., for the machine of which the accompanying engraving is an illustration; it presents a view of the machine in perspective, as it stands upon the mill floor, and shows the outline of the structure, though not as fully as if exhibited in sectional drawings. It planes boards and plank with a series of line cutters, which are so attached and adjusted to side plates, that the heels of the stocks hold together the grains of the board and prevent the material from being forced asunder by the feeding power; the heel of the stock being elastic, while the edge of the knife retains its relative graduation.

The stocks are made elastic by being bolted at the ends to hinged bars; these bars are attached by pins to bolts, which are worked in sockets formed in the side plates, to which all the stocks are adjusted. The vibrating centre of the stock hinge is in line with the cutting edge of the knife. By this arrangement, the heel of each stock is allowed to rise and fall without changing the relative graduation of the series of line cutters. readily be seen, is a very great improvement. and is all important in the practical operation of line cutters.

In the machine patented by Sir Samuel Bentham in 1791, as will appear by reference to the 5th volume of the “Repertory of Arts,” a series of line cutters is described as linked together, of sufficient number to plane a board to a uniform thickness in one operation, and graduated to the different thickness of shavings, “the foremost set rank for the sake of riddance, and the last set fine for the sake of smoothness.”

He also describes the stocks as elastic and as being held very firm upon the board by weights, or otherwise, and kept in position by pins working in slits in the side plates. A serious difficulty in the Bentham machine arose from the fact that the edge of the knife yielded with the elastic stock; but the graduation of the shavings in the Beardslee machine is uniform, the edge of the knife retaining, with reference to the bed, a relatively fixed position, like the centre of a revolving shaft. Neither in the Bentham machine, nor in any other hitherto constructed, -has the principle of the self-adjusting throat been developed until it was introduced in the Beardslee Planing Machine. The novelty and importance of the improvement cannot fail to strike the mind of every scientific mechanic. By means of this arrangement the sole of the stock always rests upon the board in the precise plane of the preceding cut, and from that plane there can be no deviation, whether the board he narrow or wide, or in whatever part of the machine it may run. The elasticity of the stock is the same, whether it is controlled by springs at both ends or by a spring at one end only. By this arrangement, also, a diffused and uniform pressure is produced along the whole line of elastic stocks. The soles of the stocks are broad, and allow the lumber to pass beneath them without depressing the surface.

The peculiar arrangement of the knives and stocks effectually obviate all the difficulties heretofore encountered in the use of line planers. As there is no intervening space between the sole of the stock and the board, defective and cross-grained boards cannot separate while passing through the machine; loose and detached portions of the board are held in position or pass out during the process of planing by the yielding of the elastic stocks. The graduation of the shaving and the thickness of the lumber are not changed by the removal of the cutters to be sharpened, as the most ordinary mechanic can readily replace the knives in the precise position which they occupied before their removal; this insures uniform thickness of the material planed.

The first knife of the series is made elastic both at the heel and the edge, with a fixed throat like the hand plane; it is held in its relative position. and prevented from moving forward or backward, by the hinge pin working in a slot, This cutter. in its operation, becomes a jacker, taking the first shaving from every board, and a shaving of equal thickness, whether the board be thick or thin; thus the whole gritty surface of the board is removed with the first shaving, which, from the vertical position of the machine, passes out before the board is brought in contact with the other knives, and they are left to operate only upon a surface previously planed.

The belts, gearing, and pullies which operate the feeding apparatus, are all placed beneath the floor of the mill, and from their position are less liable to be deranged. The gears are of great strength, capable of passing any material through the machine. The principal driving wheel weighs 676 lbs. and the rollers are operated by three gear wheels, which are of great strength and equal size.

The rollers and the sectional plates form a clamping apparatus which conveys the boards or plank through the machine while subjected to the action of the knives. This apparatus is peculiar in its structure and movement. There is an endless sectional platform, which is carried forward by pinions working in racks. Thus the successive plates are propelled beneath the series of cutters, rising and descending at each end in concentric grooves, and returning along the back of the machine. The sectional plates pass over a true lubricated bed, and being made of iron and planed to a uniform thickness, they form a perfect plane while passing beneath the cutters. This device is of great practical importance in connection with the use of line planers, as any variation of the bed upon which the lumber rests, not only produces an unequal thickness, but also effectually destroys the action of the cap. The cap, when placed in the relative position to the edge of the knife, which is required for a given shaving, serves the two-fold purpose of holding the board to the bed. and preventing the grains of the wood from separating in advance of the cutting edge of the knife. If the bed be unequal, the shaving will be unequal also. The cap must be removed from the cutting edge a sufficient distance to allow the greatest thickness of the shaving to be removed, and of necessity ceases to operate at all as the thickness of the shaving diminishes. But with the level bed of the Beardslee Machine, the thickness of the shaving is uniform, and the action of the cap is steady, equal, and unvarying. The machine is constructed entirely of metal, and in the most substantial and durable manner; it is less liable to derangement and injury than any other planing machine in use; it requires but a small proportion of the power which is requisite in the Woodworth machine to do an equal amount of work. The cutters perform more than ten times the service without requiring to be sharpened. The machine planes lumber of every kind, and planes it equally well, whether it be one-fourth of an inch or three inches in thickness; it produces a beauty of surface and a uniformity of thickness never before equaled by any machine in this country. The quantity which it will plane in a given time is almost incredible, as its only limit is the quantity which can be fed into the machine.

The newly invented Matcher, for tongueing and grooving boards and plank, which is used in connection with this machine, is a device not easily described without the aid of drawings, but exceedingly simple and beautiful in its operation. It has never before been equaled by any tongueing and grooving machine, either as to the quantity or quality of its work. It produces a tongue and groove far superior to any that can be made with the hand match planes by the most experienced workman. It is so arranged that it is either operated separately or in connection with the surfacing machine, and lumber is run through both the surfacing and matching machines without any more preparation than is required for the Woodworth Machines. In one operation, the lumber can be planed on both sides in the Beardslee Machine, and at the same time rabbited and beaded or jointed. The planing machine, as well as the matcher, are now in full operation at the machine shop of F. & T. Townsend. on Elk Street, in the city of Albany, N. Y., where Mr. Beardslee is extensively engaged in the manufacture of his machines.

US Patent: 8,098

http://datamp.org/patents/displayPatent.php?number=8098&typeCode=0 |

|

1851 F. & T. Townsend Foundry, Beardslee's Elastic Cutter

1851 F. & T. Townsend Foundry, Beardslee's Elastic Cutter

|

|