|

Title: |

1908 Article-Atlas Engine Works, 4 Valve Medium Speed Engine |

|

Source: |

The Engineer, V45, 01 Jan 1908, pg. 57 |

|

Insert Date: |

7/26/2017 7:50:23 PM |

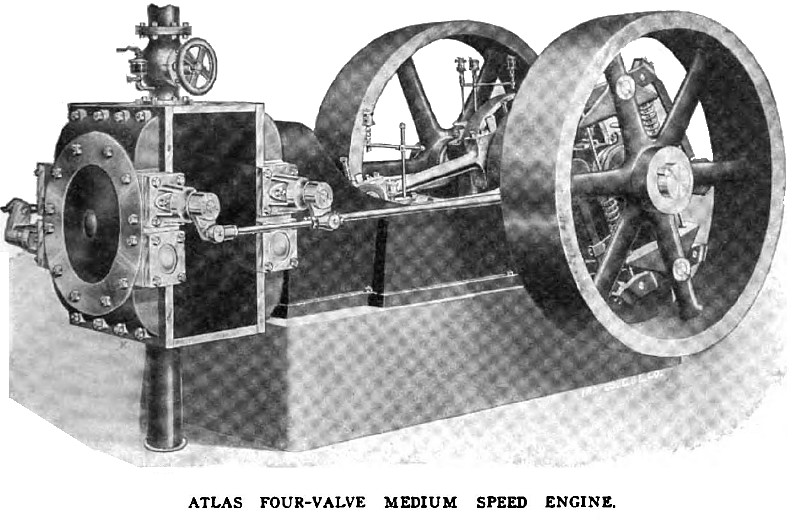

ATLAS FOUR-VALVE-ATLAS ENGINE WORKS, INDIANAPOLIS, IND.

Several styles of engines are made by the Atlas Engine Works, including four-valve automatic, single-valve automatic and throttling engines, the three being made in center crank and side crank patterns. The four-valve has Corliss valves placed in the heads of the cylinder and operated by positively connected cranks driven from a shaft governor of the centrifugal type which changes the throw of the eccentric.

The general appearance of the engine is shown by the illustration herewith. A deep box pattern of bedplate is combined with the Tangye frame to give strength and symmetry. The main bearing is made in three parts with a wedge for adjustment the full length of the bearing. The bottom shoe and two quarter-boxes form the sections. The crosshead is of slipper form with a cylindrical bottom surface and flat tops, all surfaces being Babbitted and scraped. The hollow piston is fitted with automatic spring packing the rings being held out by German silver spiral springs.

The ends of the connecting rod are of solid strap construction, giving great convenience in the removal and replacement of brasses. In the governor two weights are suspended from spring crossheads which are pivoted on opposite arms of the wheel and control the eccentric. As the engine tends to speed up the ball weights tend to fly outward and at the same time the crossheads tend to separate, both operations swinging the center of the eccentric nearer to the center of the shaft.

By placing the valves of the four-valve engine in the cylinder heads and making them double ported, the length of the ports or clearance is reduced to a minimum, and the use of the Corliss Valve insures quick opening and closing. The steam valves are operated by one eccentric and the exhaust valve by another, the steam eccentric being, of course, controlled by the shaft governor. The exhaust eccentric is keyed fast to the shaft, this arrangement allowing a cutoff range from zero to three-quarters stroke. On the engine as shown the eccentrics are on opposite sides of the shaft. On the heavy duty type the eccentrics are put at the same end of the shaft and the valve stems all brought out on the same side of the cylinder.

A single-valve engine is also made in smaller sizes than the four-valve and for situations where a less first cost is desired. The valve used is a balanced flat valve with double ports and spring pressure plate. The cylinder and steam chest are cast in a single piece and the heads and steam chest cover are ground to a steam fit and held by stationary studs. For driving the valve a crosshead casting is firmly fastened to steel parallel guide rods by set screws and these rods run in Babbitted stands which are bolted to the bedplate. The eccentric is controlled by the same governor as used for the four-valve type. |

|

1908 Atlas Engine Works, 4 Valve Medium Speed Engine

1908 Atlas Engine Works, 4 Valve Medium Speed Engine

|

|