|

Title: |

1908 Article-Billings & Spencer Co., Drop Hammer, Model C |

|

Source: |

Southern Machinery, V8, Nov 1908, pg. 11 |

|

Insert Date: |

10/27/2017 12:36:11 PM |

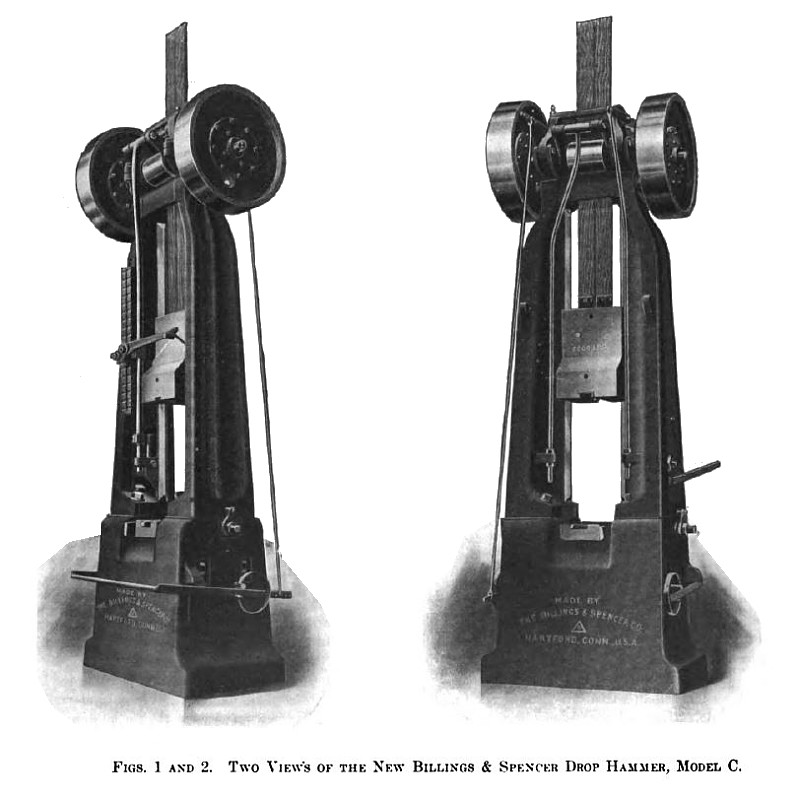

BILLINGS & SPENCER IMPROVED DROP HAMMER

The Billings & Spencer Co., Hartford, Conn., have made a specialty of the drop forging business for a period of about 40 years in the manufacture of machinists' tools and forgings of all descriptions. During that time they have used many of the various styles of drop hammers that have been on the market. An opportunity was therefore afforded them to note the defects of these hammers and where improvements could be made. About 20 years ago the company began the manufacture of its own hammers, incorporating the improvements and best design of that day. The first hammers were known as the Model A. In time, further improvements were made and new features adopted which resulted in their well-known Model B hammer. This machine has won a wide reputation for its durability and efficiency in turning out high-grade work.

Recently, however, the demand for much heavier work, and a correspondingly greater efficiency in the forging plant, has prompted them to consider further possible development of their hammers to meet this demand. They have, therefore, been experimenting for the past few months with a new model, which after the severest tests in their own drop shop, they claim, has shown itself a splendid piece of mechanism and thoroughly capable of all up-to-date work. The new machine, known as Model C, Fig. 1, is not only much stronger than the old, weight for weight, but it incorporates several distinctive features.

An improved board clamp catch-up is employed, which eliminates the latch and connections at the side for holding the ram aloft. This board clamp is of entirely new design and is located at the extreme top of the machine, above the friction rolls or lifting device. In this position is it impossible for oil to get between the clamp and board, which has heretofore been the cause of much inconvenience where board clamps have been used. Positive action is assured in the new clamps by the operation of cams or eccentrics controlled by a foot lever attached to the base of the machine.

Another important feature is in the novel adjustment of the rear friction roll by means of an eccentric, which is a duplicate of that used in engaging the front friction roll. The two rolls with their eccentrics are, therefore, interchangeable, and by this means of adjustment a true alignment between the lifting board and rolls is always preserved.

A new form of bronze bushing is introduced on the eccentric bearings, which is easily and quickly removed and replaced. The same manner of adjustment, namely, an eccentric, is employed on the rear board clamp. These adjustments, of the rear friction roll, and rear board clamp, are made by means of bars attached to the eccentric and running down parallel to the uprights to within easy reach of the operator on the floor, as shown in Fig. 2, a very desirable thing in itself. An improved method is also employed in attaching the head to the uprights.

The uprights used on the new model are of special design and will greatly reduce the possibility of breakage, the distribution of metal being such a to afford the maximum strength. The cross section of the uprights is that of a letter V, the apex forming the guide for the ram. A longitudinal rib running its entire length on the outside, adds strength to the upright. An important feature is that the uprights remain solid throughout their lengths, no weakening perforations being necessary in the placing of attachments. A new lateral adjustment for the uprights is employed at the junction of the base and uprights, which the manufacturers claim is a marked improvement on anything used heretofore.

The releasing lever attached to the outside of the left-hand upright has an improved adjustment in the form of a modified rack, intervals of 1½-inch, allowing the ram to be released at any desired height.

Other minor improvements might be named, which, together with the above, go to make up a thoroughly efficient and modern machine. |

|

1908 Billings & Spencer Co., Drop Hammer, Model C

1908 Billings & Spencer Co., Drop Hammer, Model C

|

|