|

Title: |

1908 Article-Chambersburg Engineering Co. -Steam Drop Hammer |

|

Source: |

Southern Machinery, V8, Nov 1908, pg. 14 |

|

Insert Date: |

10/31/2017 9:31:11 PM |

CHAMBERSBURG STEAM HAMMERS.

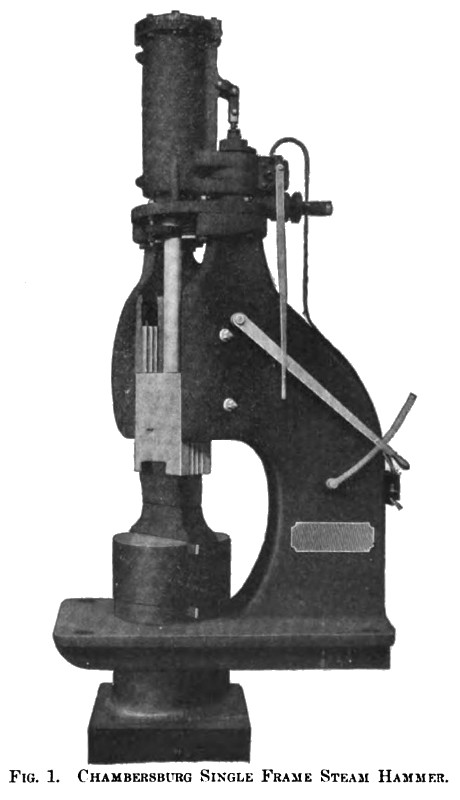

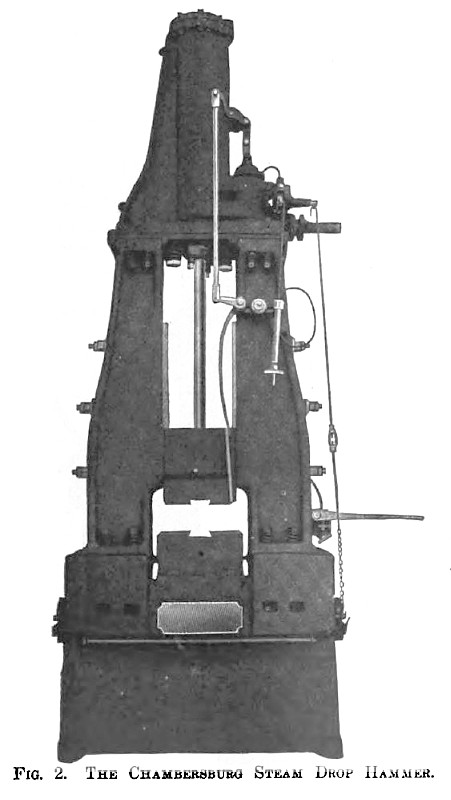

A STANDARD single frame guided ram steam hammer as built by the Chambersburg Engineering Co., Chambersburg, Pa., is shown in Fig. 1. This style of hammer is used for general forge work and is built in sizes from 250 to 5,000 pounds falling weight. They are fitted with the well-known Chambersburg guide for taking up the wear of the ram, and it is this feature that has particularly recommended these hammers to the trade, some 850 having been built and furnished by this company during the eleven years it has been in operation. These guides are hung in pockets planed in the frame, thus taking the weight of the guide from the holding-back bolts. The adjustment is made by a steel taper shoe which has a bearing the full width and length of the guide, the wear of the ram being accurately taken up. The oval anvil and anvil cap are furnished, as the manufacturers have found from practice that this shape, having more metal around the notches, adds to the strength and life of the anvil. The hammers of this company are also built in the single frame guided rod style for locomotive frame work, and in the double frame guided ram and guided rod designs up to 24,000 pounds falling weight. Fig. 2 shows a Chambersburg steam drop hammer as built in sizes from 300 up to 10,000 pounds falling weight for all kinds of drop forge work. The builders claim that steam drop hammers are superseding the board drop hammer, owing to their wide range of work, great output and low cost of maintenance, there being no belting or shafting or trappy parts. This company have always made a specialty of the steam drop hammers, claiming to be the pioneers in developing its possibilities to the drop forge trade and improving its design from time to time in order to make it the most up-to-date and economical tool possible. These special features have made it a standard with many of the leading drop forge concerns.

A steel tie plate lips over the base of the cylinder and the top of the frames, keeping these parts in line and relieving the strain from the bolts. The anvil also lips the base of the frames on four sides, preventing them from shifting and taking up much of the shock on the frame to anvil bolts. The entire hammer is designed to be thoroughly rigid throughout so as to keep the dies in alignment. Where. the work is severe steel frames are furnished. The anvils. are rated either 15 or 20 to 1 and made from best quality air furnace iron or steel, depending on the character of the work.

The valve mechanism on all these hammers is of simple and durable design, giving the operator perfect control and it is not liable to get out of order. It is so arranged that lost motion due to wear is taken up by gravity.

Hydraulic machinery, such as outside hemp-packed riveters, cranes, accumulators, plumps and hydraulic forging, flanging and wheel presses for boiler and car shop. works, are also manufactured by this company, and their steam hammers and hydraulic machinery will be found in many of the leading railroad locomotive and car shops. |

|

1908 Chambersburg Engineering Co. -Steam Drop Hammer (Fig. 1)

1908 Chambersburg Engineering Co. -Steam Drop Hammer (Fig. 1)

1908 Chambersburg Engineering Co. -Steam Drop Hammer (Fig. 2)

1908 Chambersburg Engineering Co. -Steam Drop Hammer (Fig. 2)

|

|