|

Title: |

1907 Images-Holly Mfg. Co., Factory Views, Part 1 |

|

Source: |

Manufacturer & Builder, V20, Feb 1888, pgs. 33-34 |

|

Insert Date: |

4/6/2018 8:16:54 PM |

The Holly Manufacturing Co. (See also parts 2 & 3.)

The illustrations shown herewith represent the works and the several departments of the Holly Manufacturing Company, of Lockport, N. Y., a flourishing establishment, largely engaged in the manufacture of improved pumping engines and machinery for water works, fire hydrants, water valves, and kindred appliances.

The company was organized in 1859, for the purpose of introducing the inventions of Birdsall Holly, which embraced, among others, a system of water supply for cities and towns by the method of pumping directly into the mains, thus dispensing with the use of reservoirs and stand-pipes. This system, which I now widely known as the Holly system, became popular from the start and at the present time is extensively in use throughout the United States. From time to time, Mr. Holly introduced improvements upon the pumping engines employed in connection with his system, its latest development being the quadruplex engine, in which four steam cylinders were employed in conjunction with four water cylinders. The first engines of this type were erected at Dunkirk, N. Y., and worked very successfully. Later, Mr. Holly adapted the compound principle to this engine, and with equally satisfactory results, the first engine of this form having been erected at Rochester, N. Y., in 1874.

In 1882, H. F. Gaskill, at present the chief engineer of the company, designed the pumping engine which has since superseded all others made by this company, and which has proved to be so unqualifiedly successful that it has given fresh impetus to the prosperity of the company and additional prominence to its operations from a mechanical and engineering standpoint.

The first engine built on Mr. Gaskill's plans was erected in 1882, at Saratoga Springs, N. Y., where it has remained down to the present time in constant use. Daily records of its duty have been kept by the engineer, in charge of it, from which it appears that it has averaged, during the entire period of its service, 105,000,000 foot-pounds for every 100 pounds of coal burned. This, it will be observed, is the average duty; when worked to the limit of its capacity, its yield would be considerably higher. So high a duty would be very satisfactory under the most favorable circumstances, but when it is remembered that this was the pioneer engine of the Gaskill type, and, therefore, to some extent an experiment, the high record it has yielded is especially noteworthy. The advance which the Gaskill engine made upon the earlier ones of Holly, will appear from the comparative statement, that the improved engines of Mr. Gaskill have yielded a duty varying from 54,000,000 foot-pounds to 87,000,000 foot-pounds, while the Gaskill engines have yielded duties varying from 102,000,000 to 125,907,000 foot-pounds.

On this point the accompanying table will give interesting evidence:

Since the successful introduction of the Gaskill pumping engine at Saratoga, above noticed, the Holly Manufacturing Company has built and disposed of 86 of the same type, representing a total daily capacity of 373,500,000 gallons.

These engines are built of vertical and horizontal pattern, and either single or compound. They combine great simplicity of construction with high economy of operation, and low first cost. We exhibit among our illustrations a view of the compound horizontal engine, and its salient features will be learned from the following concise description; The high-pressure cylinders lie above the low-pressure ones. The steam connections between the two are straight and direct, and the steam is admitted to the low-pressure cylinders by slide valves. The high-pressure cylinder is supplied with steam by poppet valves, forced to their places by springs contained in dash-pots. The four rocking beams for working these valves are visible directly above the steam chests. When the high-pressure piston is on its back stroke, the low-pressure piston is making its forward stroke. The two are connected by a short walking-beam, which works in a vertical plane between the guide bars of the parallel motion. Short links connect its ends with the piston rods. The main pitmen are connected to the upper end of the walking-beam; these drive the fly-wheel. The pump cylinders are in the line of the lower or low-pressure cylinders, so that with them they preserve the relation of a direct-acting pump. The pump valves are of bronze and India-rubber, and work by gravity only. The displacement is by a plunger working through a diaphragm in the center of the water chamber.

The location of the works of the Holly Manufacturing Company, in respect to the command of an abundance of cheap power and of ample facilities for the shipment of its products, either by water or railway, is in all respects most advantageous. They are situated at Lockport, N. Y., on the Erie canal, opposite to the famous locks. One of our illustrations shows a general view of the works. The works are run, of course, by water power. The prime mover is a turbine water wheel, the water to run it being drawn through a long tunnel from the upper level of the canal above the last lock. This level is that of the lake, and the works stand, therefore, in direct communication with the waters of Lake Erie. The total fall is 56 feet, and the supply of power which it affords is so much in excess of that needed at the works, that a large surplus is leased out to other industrial establishments adjacent to them. Side tracks from the New York Central Railroad pass directly into the company's works. The facilities for shipment, therefore, either by rail or canal, are all that could be desired.

The general view shown in our illustrations gives some idea of the extent of the company's works, which cover about 4¼ acres. Power is carried by shafting from the turbine house to all the departments of the establishment. The numerous buildings are all built of the limestone which is plentiful in the neighborhood.

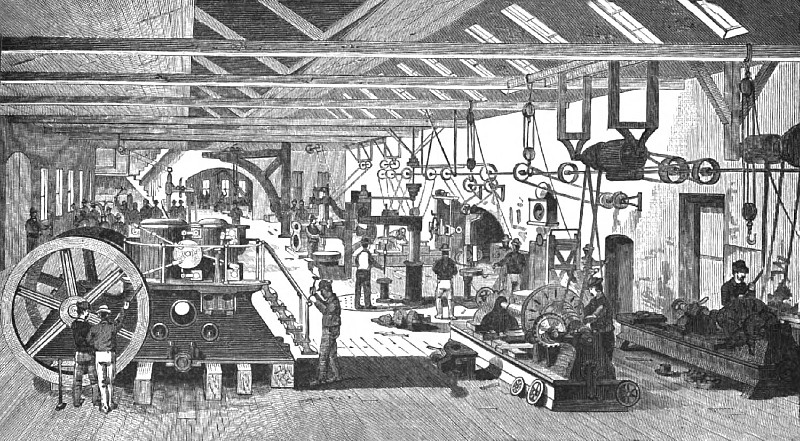

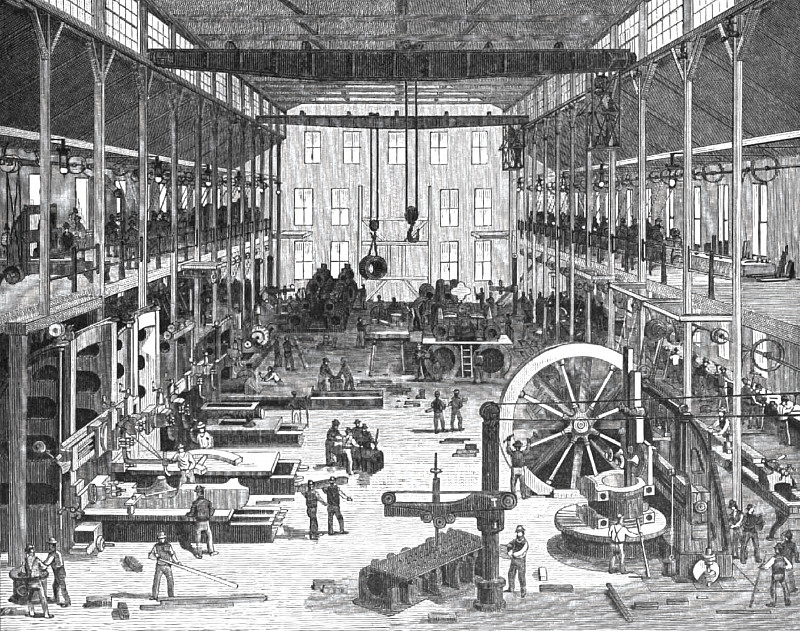

The views of the interiors of the several departments, shown in the accompanying illustrations, will give a fair idea of their extent and the completeness of their equipment. The old erecting shop is devoted to the construction of the Gaskill vertical and horizontal direct-acting engines, of which a nearly-completed one is seen in the foreground of the picture. The new erecting shop is supplied with the best facilities for rapidly disposing of the heaviest class of work. The machine tools are of large size and capacity, and the handling of large and heavy masses is readily effected by means of the overhead traveling cranes.

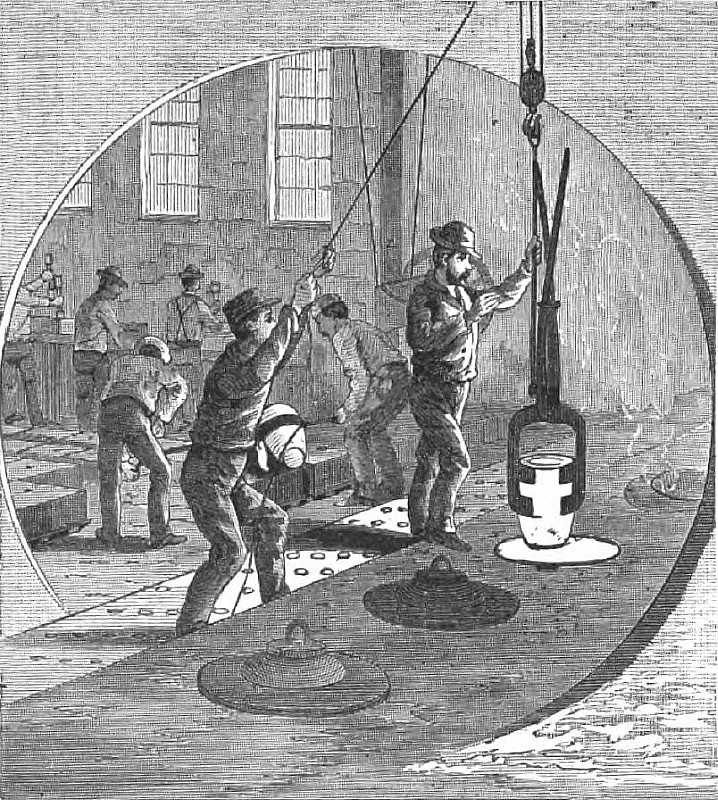

Our view of the pattern shop exhibits a specimen of the work now going on for the construction of a 20,000,000-galion pump for the city of Buffalo, N. Y. Our picture of the iron foundry gives a very good idea of this department of the works. It covers a large floor area and is admirably fitted with every facility for the heaviest casting work. The whole length of the foundry is commanded by the overhead traversing crane, and other parts of the floor space are commanded by jib cranes, disposed at convenient distances from each other. Another view shows the operations of the brass foundry, in which the brass-work, journals, etc., of the engines are made. Another view exhibits the interior of the lower shop, devoted to a great variety of work. The upper shop, also pictured in part, is given over to the lighter class of work. In this, one of the Holly regulators is shown. This piece of mechanism is used in connection with the Holly direct-supply system, and effects the automatic regulation of the pressure. The regulator being set to any desired pressure, maintains this pressure automatically with in very narrow limits. The regulator does not act directly upon the cut-off of the engine, but simply throws into action gearing connected with the engine, which indirectly effects the desired object.

Another portion of the works (not shown by any of our illustrations) is devoted to the manufacture of fire hydrants and water valves, in the production of which, of all sizes and for every form of fire service, the Holly Manufacturing Company is largely engaged.

The company employs about 500 men and is at present engaged in building about thirty pumping engines, varying from one to twenty million gallons daily capacity. The main office of the company is at Lockport, N. Y.; branch offices are located at New York, in charge of C. G. Hildreth, 45 Broadway; at Chicago, in charge of P. II. Linnean, 51 Home Insurance Building, La Salle street; and at Boston, in charge of W. E. Decrow, 27 Federal street. The company's officers are, Hon. T. T. Flagler, president; H. F. Gaskill, vice-president and engineer; H. H. Flagler, treasurer. |

|

1907 Holly Mfg. Co., Old Erecting Shop

1907 Holly Mfg. Co., Old Erecting Shop

1907 Holly Mfg. Co., New Erecting Shop

1907 Holly Mfg. Co., New Erecting Shop

1907 Holly Mfg. Co., Brass Foundry

1907 Holly Mfg. Co., Brass Foundry

|

|