Image

Manufactured By:

J. A. Fay & Co.

Keene, NH; South Keene, NH; Worcester, MA; Norwich, CT; Cincinnati, OH

|

|

|

Title: |

1882 Images- J. A. Fay & Co., Factory Views |

|

Source: |

Scientific American, V47, 30 Dec 1882, pg. 415-418 |

|

Insert Date: |

5/23/2018 12:44:33 PM |

In the invention, manufacturing, and introducing of wood working machinery, J. A. Fay & Co. have been the pioneers; their name is known all over the world, and their machines are in use in every land. They are still as full of the pioneer spirit as ever, being constantly on the alert to accede to the demand of the times by introducing everything new or useful in their department of manufacture. This business, which has made the name of Cincinnati known at the remotest corners of the earth, was not built up in a single day. Its growth has been like that of the oak from the acorn, slow but sure, until its trade and trade ramifications are enormous. Successive years only add to and increase its volume.

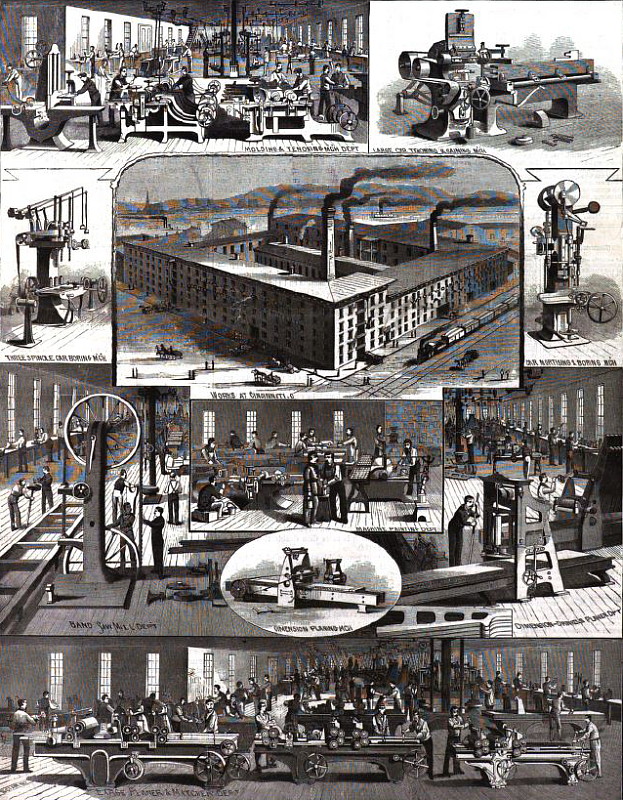

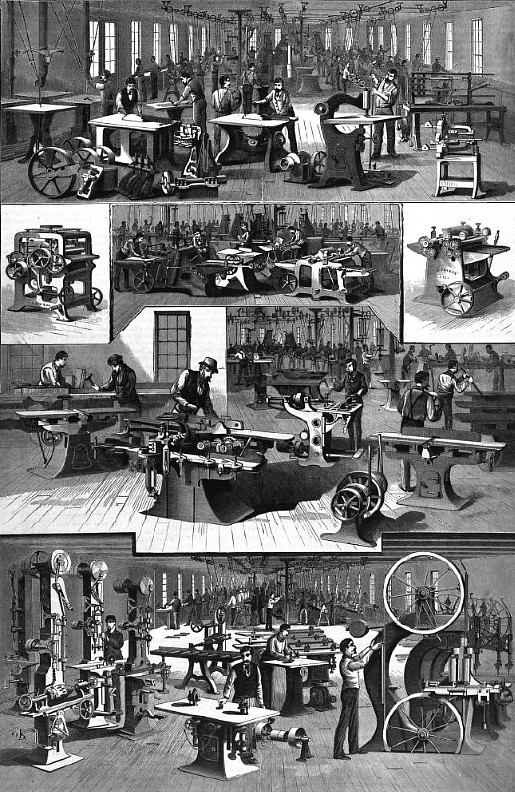

We present to our readers an engraving of the extensive plant of this house, with an inside view of a few leading departments, together with facts of its history, which will be to many very interesting. (See our first page.)

In 1834, George Page, of Keene, N. H., invented and began the manufacture of foot mortising machines. These were the first machines of the kind made in this country, if not in the world.

In 1835, Mr. J. A. Fay, of Marlboro, Mass., associated himself with Geo. Page, and under the firm name of Page & Co., Mr. Fay introduced the Fay tenoning machine for tenoning and coping doors, sash and some other wood-working machines. The country was not then opened up by railroads and was sparsely settled, and Mr. Fay found a market for his machines by taking them in a wagon over the hills and through the valleys, introducing them in various sash and door shops.

These machines were so wonderfully labor-saving, as compared with the old tedious and laborious hand process of working, that it was but a short time before their merits became established, and a rapidly increasing trade followed. In the meantime, Mr. Edward Joslin, of Keene, N. H., who had been in the employ of the company as a workman from the beginning, joined with Mr. Fay, and bought out the business of Page & Co. He was of a quite inventive turn of mind, and from this time the firm introduced various laborsaving wood working machines. This was in 1841. In 1848, their business having increased beyond the capacity of their works, they started branch manufactories at Worcester, Mass., and at Norwich, Conn. In the manufactory at Norwich, Mr. C. B. Rogers, now deceased, had a large interest and was the resident partner. The business increased rapidly and steadily, until, eleven years later, or in 1852, the enterprise was so great that they felt they must have a Western connection.

This was before there were railroads traversing the West and Southwest, as now; and in this year they established, at the corner of Augusta and John Streets, Cincinnati, another branch house of J. A. Fay & Co., with Mr. John Cheney and Mr. E. Reed as resident partners. Later in the same year, while Mr. Fay was in Richmond, Va., with a view of establishing a branch house in the South, he died. In 1855, his executors sold out his business at Norwich to C. B. Rogers & Co., and later, in 1862, discontinued the Worcester house, and still later, in 1863, discontinued the parent house at Keene, N. H., transferring most of the important machines to the Western house at Cincinnati.

In 1861, 21 years ago, Mr. Cheney retired, and Mr. W. H. Doane, who had been several years with the company, became the leading member of the house and manager. Its history during these 21 years is marvelous. And to recount its progress would involve the history of Cincinnati itself.

In 1860, the establishment of J. A. Fay & Co. was considered one of the largest in the West, but since that time it has more than quadrupled its size, and now it covers more than six acres of floor space, and furnishes steady employment to about 400 skilled artisans and mechanics, who, aided by the most improved labor-saving machines, are able to turn out the work of more than 2,000 men. The buildings are five stories in height and of the most substantial character and are provided with four power elevators. The motive power is supplied by a Corliss automatic cut-off engine, which takes its steam from a battery of Babcock & Wilcox sectional wrought iron boilers of 250 horse power. Over 2,000 feet shafting, and 5,000 feet of belting are in use in the different departments. The strictest system pervades the whole establishment; there are all together 15 divisions, each with its own foreman and all under the immediate supervision of a general superintendent. The foremen are especially selected from among the most skilled workmen of a department, and all vie with each other upon the general excellency of the product of their different departments, the aim of each being to excel the other.

To form a correct opinion regarding the immense number and variety of the machines made at these works, they should be., visited; but for the benefit of our foreign readers, we will enumerate a few of the principal ones and the uses for which they are designed.

Of car building machines for railroad shops, they make about thirty-five different varieties. Of planing, including matching, machines, over twenty, adapted to all kinds of work, from the smallest cigar box and cabinet making machines to those for the largest possible requirements, and weighing many tons. The number of wheel and carriage making machines, including machines for making and finishing every part of the wheels and carriage, is between thirty and forty, and of sash and door machines about the same number. Of cabinet making, including furniture, machines, twenty-five or more; agricultural implement machines, about twenty-five; and bridge building machines, about twenty-five. Of band sawing machines, they build ten sizes, from the largest costing two thousand dollars with a capacity to saw log six feet in diameter to the smallest size, costing one hundred and fifty dollars and suitable for all common scroll and curve cutting.

To describe the capabilities of the machines would require a volume, but their utility and power may be inferred from a brief description of a few. Among the more ponderous and massive are those designed for railroad car building. In fact, it may be stated that these are of a special character, particularly designed to decrease very materially the labor and cost of handling heavy timber; and to such perfection have these devices attained, that in dressing car sills, where formerly several machines were required to dress and square up fifty in a day, one machine will now do the same amount of work in an hour. The power of a large timber dressing machine is so great and its execution so precise that timbers even up to twelve inches square and of any length can be finished on all four sides at one cut at the rate of thirty feet per minute. If required, it will reduce one inch by the top cutting cylinder and the same with the heads which cut upon the sides. This, exclusive of the cut of the lower or under head, would make three inches off the surface of a timber, or equal to more than one inch reduced at one cut from a timber twenty-four inches wide. The vertical car tenoning machine, which takes the sill or timber from the machine first described, makes single, double, or triple tenons, first on one end, then on the other, without reversal. This one machine alone, it is said, saves the labor of sixty men. Another machine, the car gaining and boring machine, is capable of automatically traversing back and forth over timbers, and at each passage cutting grooves of any desired depth or width.

Slops regulate the precise distances apart, so that exact duplicates of the gains can be made in any part or number of pieces of timber without laying out. A vertical boring attachment completes the holes in the timbers for joint bolts while it is on the carriage of the machine, thus saving the labor of additional handling and separate machines. This machine is capable of doing the heaviest class of work required. Heavy mortising and boring machines are constructed that will "beat" mortises up to two and a half inches in width and of any ordinary depth, the peculiarity of which is the graduated movement of the chisel bar, which commences from a still point above the upper extreme throw of the chisel mandrel, and working down gradually into the wood without jar to the operator. In this department alone are turned out machines for boring with one, two, or three spindles either vertically, horizontally, or radially, that will finish a piece of limber in from four to five minutes. In all these machines, the quality as well as the quantity of the product are the leading features attained, and these remarks will apply with equal force to every class of machines made in the factory, regardless of the grade of work for which they are intended. Had we space, we might extend our review of the capabilities of the different machines to an unlimited extent. It is, however, a fact that the largest variety of machines for wood working purposes to be found in any manufactory in the world is made at this establishment, and its facilities rank it among the most extensive establishments of the kind in the world. To this house the manufacturers of the United States look for their best equipment’s. Here, furniture makers, wheel and carriage makers, planing mill owners, and other users of labor-saving wood working machinery look for the highest standard of excellence and perfection. The striking originality of the machinery, possessing as it does all that is desirable in accuracy of workmanship, precision of action, strength of construction, solidity, and uniformity, has attracted not only the attention of manufacturers, but also the executive departments of foreign governments, who have given the firm many orders.

The house of J. A. Fay & Co. has many established agencies and correspondents throughout the world. The following is a partial list of their principal representatives:

Messrs. Cayley & Cayley, Brackley St., Golden Lane, London, are the agents for Great Britain and Ireland. The same extensive house has also a branch in Hamburg, and are also agents for Germany, Austria, Norway, Sweden, and Prussia. The well-known house of H. P. Gregory & Co., of Sydney, represent the company in Australia.

In the city of New York, the George Place Machinery Co. are the general agents. Utilles Baird, of Water St., Pittsburg, Pa., is the agent of that city. At Detroit, Mich., the house is represented by James Jenks, Nos. 48, 50, 52, and 54 Randolph St. At Chicago, the firm have a branch house at 207 and 200 Lake St., over which Mr. John A. Roche, a mechanical engineer of reputation and ability, presides.

At St. Louis, Mo., the company have their own warehouse at 720 North Second Street, under the management of Mr. C. C. Harris, well known in that part of the country. On the Pacific coast, both at San Francisco, Cal., and at Portland, Ore., the house is represented by H. P. Gregory & Co., Market Street, San Francisco, who have extensive houses at each place. The general agents have also many minor agencies under their management and jurisdiction.

Large shipments are constantly being made to Great Britain, Russia, Germany, Italy, Sweden, France, Japan, Africa, South America, New Zealand, Mexico, and other countries. In all of these countries, their machines are looked upon as unrivaled.

The many displays of machinery by this house at the international expositions have done not a little toward bringing the excellence of their manufactures before the public, especially as at all of the expositions they have received the highest awards, which was the case at Paris, Vienna, Australia, etc.

The prominence gained for this house during twenty-one years, from 1861 until the present time, is undoubtedly largely due to the most indomitable energy, sagacity, mechanical skill, and executive ability shown by its president, Mr. W. H. Doane, and Mr. D. L. Lyon, secretary, who have lived to see the business of the house increase to the most extraordinary dimensions, with its reputation extending throughout the whole earth. |

|

1882 J. A. Fay & Co., Factory Views

1882 J. A. Fay & Co., Factory Views

1882 J. A. Fay & Co., Factory Views

1882 J. A. Fay & Co., Factory Views

|

|

|

|