|

Title: |

1857 Article-Sparke & Co., Sawing Machine |

|

Source: |

Mechanics Magazine, V67, 24 Oct 1857, pg. 385 |

|

Insert Date: |

7/4/2018 8:46:08 AM |

Messrs. Sparke arid Co., of the Thorn-lane Foundry, Norwich, engineers and founders have patented the following improvement in sawing machinery. The first part of their invention relates to that part of sawing machinery which is employed to give motion to the timber under operation for the purpose of bringing it up to, and keeping it in contact with, the saw during the cutting, and of withdrawing it from the law when the cut is completed; and this part of the invention consists in the employment of a chain or rope, one end of which It attached by claws to the timber, and the other end of which is passed partially around two friction rolls or pulleys, one of which is fixed upon a spindle driven by power, and the other is carried on an axle at the extremity of the short arm of a lever, or of the short arms of two similar levers. Upon the same axes as the two friction rolls or pulleys, and rigidly connected with them, are two toothed wheels, which gear into each other, for the purpose of rendering the motions of the rolls or pulleys perfectly isochronous. A guide roll is fitted upon the end of the saw bench for guiding the chain or rope from the timber to the rolls or pulleys.

The second part of the invention relates to the mode of driving reciprocating saws, or saws which act upon the material to be cut by successive strokes, and consists in the employment of a crank arm, the length of which may be varied when it is desired to change the length of the saw's stroke, such crank arm carrying at its extremity a pin which works in a transverse slot in the frame of the saw, and which, as the crank arm rotates, imparts the necessary reciprocating motion to the saw. Instead of a crank arm and pin, a disc and adjustable pin, or other equivalent contrivance may be employed.

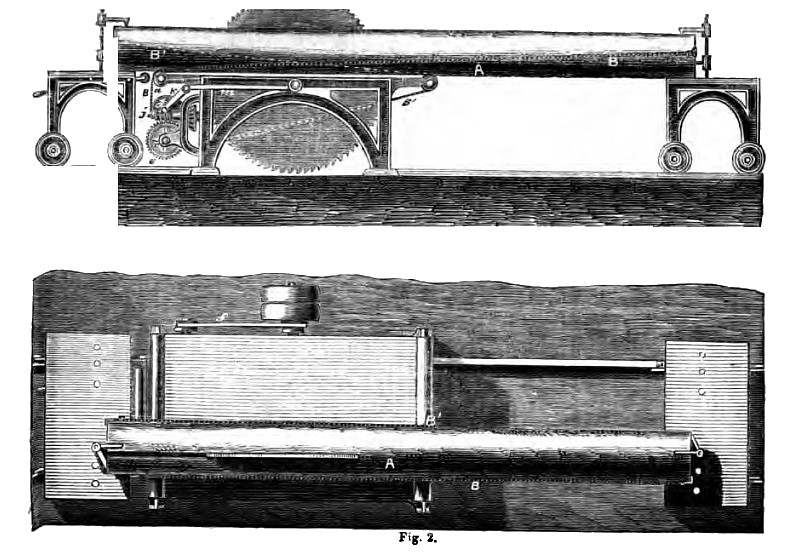

The accompanying engravings represent the manner in which the invention is carried into effect. Fig. 1 is a side view, fig. 2 a plan, and fig. 3 an end elevation of a circular sawing machine fitted with the improved apparatus for bringing the timber to be cut up to the saw, keeping it in contact with it, and withdrawing it from the saw when the cut is completed. The machine is formed with a frame, part of which run on rails; and the tree, A, to be cut, is attached thereto by dogs. This frame, together with the circular saw, is formed and fitted as usual, or in any other suitable manner. In this machine two ropes, B B' (the latter shown partly in dotted lines), are employed, the former Tor imparting a forward motion to the timber, A, and the latter for giving it a backward motion. The rope, B, is attached at one end by a claw to the timber, A, and is thence led over the roller. A, down under a pulley, c, and, ascending on the other side of this pulley, passes under and then over a second pulley, d, and then falls slack to the ground. The lower pulley, c, is mounted upon an axle driven by a worm wheel, e, to which motion is transmitted from the saw spindle through a belt, f, a spindle, g, a bevel pinion, h, a bevel wheel, I, and a worm, j. The upper pinion, d, is mounted upon an axle carried by levers, kk, which is fixed on a rocking shaft, l. By raising or depressing the lever, m, which is fixed on this shaft, l, the amount of friction exerted upon the rope, B, between the pulleys, c and d, may be increased or diminished in such a manner as to regulate the speed with which the timber is moved, either by allowing the pulleys, c and d, to slip more or less within the rope, B, or by nipping them tightly against it. A cog wheel is mounted upon the axle of each of the pulleys, cd, so as to gear into each other, in order that the pulleys, cd, may be made to move with the same surface speed. The rope, B’, by which he timber is run back from the saw, may be acted upon by an arrangement of apparatus similar in construction and in action to that just described, the pulleys being made larger in this case, to give it a greater speed, if desired.

GB Patent: GB-185,700,987

http://datamp.org/patents/displayPatent.php?number=185700987&typeCode=0&country=GB |

|

1857 Sparke & Co., Sawing Machine

1857 Sparke & Co., Sawing Machine

|

|