|

Title: |

1880 Article-John McDowall & Sons., Wood Planing Machine |

|

Source: |

Woodworking Machinery, Its Rise, Progress and Construction, 1880, pg.94-95 |

|

Insert Date: |

7/10/2018 4:56:02 PM |

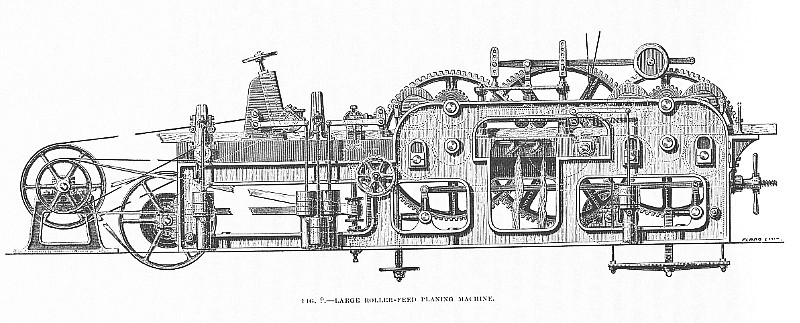

Our illustration (fig. 9) represents a side elevation of a wood-planing machine from the designs of Messrs. John McDowall and Son, of Johnstone. The timber is fed by means of four pairs of turned rollers, and the top ones are arranged to rise and fall to suit varying thicknesses of wood. Plane irons, fixed in a movable plane-box or drawer, operate on the underside of the timber, which, when rough or dirty, is first prepared by a set of revolving irons placed in front of them. A pair of revolving plane-irons operate on the upper surface of the wood, whilst two sets of plane irons, fixed on vertical spindles, act, at the same time, on the edges; thus, the whole four sides of a board are planed at once.

The blocks carrying the side spindle cutters are made removable, to facilitate the sharpening or setting of the cutters. For driving the machine two countershafts are used. One of them is placed at the delivery end of the machine, and is fitted with fast and loose pulleys, which are driven from the main mill shaft, and pulleys are also fitted on this countershaft, to drive the top and side cutters and feed motion. Another countershaft, with pulley to drive the bottom cutters, is usually placed underneath the machine. The bottom-feed rollers are fitted with bushes, beneath which a 'liner' can be placed to raise them, should they, through wear, sink below the surface of the table. The whole machine is strongly made and is arranged to work timber at speeds varying up to 60 ft. per minute, according to the variety or condition of wood being operated on. |

|

1880 John McDowall & Sons., Wood Planing Machine

1880 John McDowall & Sons., Wood Planing Machine

|

|