|

Title: |

1912 Article-Hulse & Co., Ltd., The New Erecting Shop |

|

Source: |

The Engineer, V114, 26 Aug 1912, pg. 130 |

|

Insert Date: |

7/24/2018 1:22:16 PM |

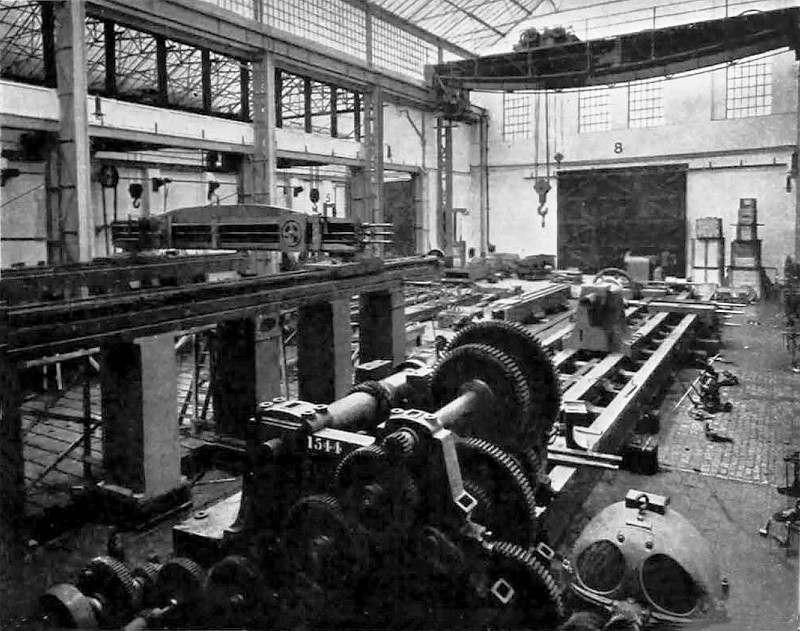

We recently had an opportunity of inspecting two large new erecting shops which have been built by Hulse and Co., Limited. Salford, and an now in full working order. As will be observed from the accompanying photographic views the capacity of these works has been considerably augmented. The main erecting shop for heavy work I 150ft. long, 65ft. wide, and 38ft. high up to the crane lift. This shop is provided with a 50-ton electric overhead travelling crane by Sir William Arrol and Sons. It has a span of 60ft. and an auxiliary lift of 7½ tons. The second new shop is 260ft. long, 40ft. wide and is 25ft. clear beneath the cranes. This shop is equipped with a 30-ton and a 15-ton electric overhead travelling crane built by Vaughans. Both shops ae splendidly lighted, the whole of the roofs being glazed on Heywood's principle. Power in the form of continuous current for testing purposes is supplied by two cables from the Salford Corporation mains, at pressures of 220 and 440 volts. The 220-volt circuit is also used for lighting. For convenience of testing machines ?tted with three-phase motors, a motor transformer is provided.

A considerable number of heavy machine tools of various types were in course of erection at the time of our visit. For turbine work there was the special pit planing and drilling machine seen in one illustration. This is for planing and drilling turbine casings at one setting. Further on we noted a large horizontal and vertical planing machine capable of dealing with turbines of the largest sizes, and a double spindle universal drilling, boring, tapping and milling machine. The huge lathe seen in one of the views has been designed for dealing with 14in. guns The firm has half-a-dozen of these on order for foreign governments. Other tools in different stages of production are planing machines with Lancashire Dynamo Company’s and Vickers high-speed equipment’s; a complete plant for 14in. guns, including rough and fine boring, rifling and chambering; a 10in. spindle, universal horizontal boring and drilling machine, which the makers claim to be the largest ever built in this country; three-spindle horizontal boring and screwing machines for the recoil cylinders of 14in. gun cradles; a special portable pit plane machine for seating’s of roller paths and a trunnion turning machine; and a complete plant for dealing with small gun cradles. |

|

1912 Hulse & Co., Ltd., The New Erecting Shop

1912 Hulse & Co., Ltd., The New Erecting Shop

1912 Hulse & Co., Ltd., The New Erecting Shop

1912 Hulse & Co., Ltd., The New Erecting Shop

|

|