|

Title: |

1874 Article-W.M.Furness & Co., Trying-Up & Four-Cutter Planing & Molding Machine |

|

Source: |

Scientific American, V31, 26 Dec 1874, pg. 406 |

|

Insert Date: |

7/30/2018 9:14:53 PM |

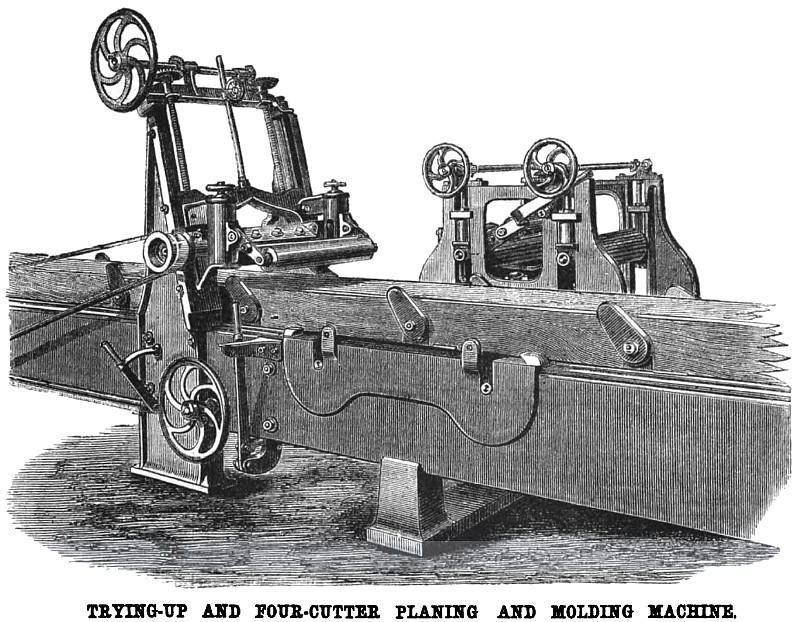

TRYING-UP AND FOUR-CUTTER PLANING AND MOLDING MACHINE

We illustrate herewith a new wood planing and molding machine introduced by Messrs. Wm. Furness & Co., of Liverpool, Eng., for the combined purposes of dimension planing, or trying-up, and planing on all four sides timber of any length, and up to a given width and thickness. The machine is shown adapted for trying-up or planing perfectly level and out of wind a piece or pieces of timber up to 20 feet long, 20 inches wide, and 16 inches thick. This is done in the ordinary way by revolving horizontal cutters, driven by two bands, one on each side of the machine, the table with the timber traveling under the cutters at the desired rates of feed, a quick return motion being provided for bringing back the table. The novel part of the machine consists in the feed works, which are here shown to be behind the table. These feed works are formed of four calender rollers powerfully geared, between which works the bottom cutter head driven from a countershaft fixed to the framing of the machine. The side cutter heads are in advance of the second pair of feed rollers and are also part of the feed works. One side cutter head is a fixture, and the other is worked in or out on slides by means of a screw. It will thus be seen that the feed works comprise the feed rollers and necessary driving gear, bottom and side cutter heads, and pressure rollers, etc. The whole is carried by four grooved friction rollers, running on two turned rods supported by the framework of the machine and a bracket at the back. When it is desired to use the feed works for tonguing and grooving, molding, or planing all four sides of the timber at once (says The Engineer, from which we select the engraving), the table of the machine is run forward till the end is almost under the TRYING-UP top cutter head, when the feed works can be easily drawn across the framework of the machine. It fixes itself in V slides; and the bands for bottom and side cutter heads having been placed on their respective pulleys—which are fixed on the ends of the spindles, so that no lacing or fastening is required—the machine is ready for work. It will work any size of timber up to 4 inches thick and 12 inches wide. By the removal of the side cutter heads, which is a very simple operation, surfacing or panel planing can be done by the top cutter head alone up to 20 inches wide. A very important feature of the machine is the rapidity with which the feed works can be removed when the machine is required for trying-up purposes, about five minutes being required. A great advantage, and worthy of attention, in this combination of two efficient machines is that they only occupy the same space as one machine, and only require one pulley upon the shaft of the mill to drive them. |

|

1874 W.M.Furness & Co., Trying-Up & Four-Cutter Planing & Molding Machine

1874 W.M.Furness & Co., Trying-Up & Four-Cutter Planing & Molding Machine

|

|