|

Title: |

1872 Article-W.M.Furness & Co., Dovetailing Machine |

|

Source: |

The Engineer, V33, 09 Feb 1872, pg. 94 |

|

Insert Date: |

8/2/2018 12:51:53 PM |

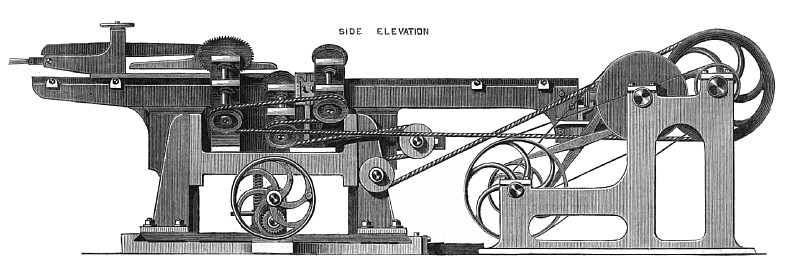

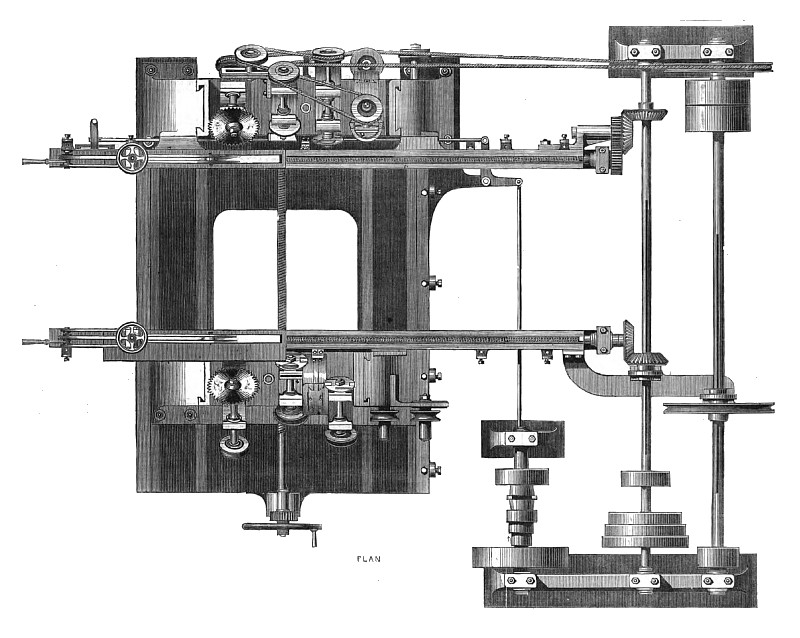

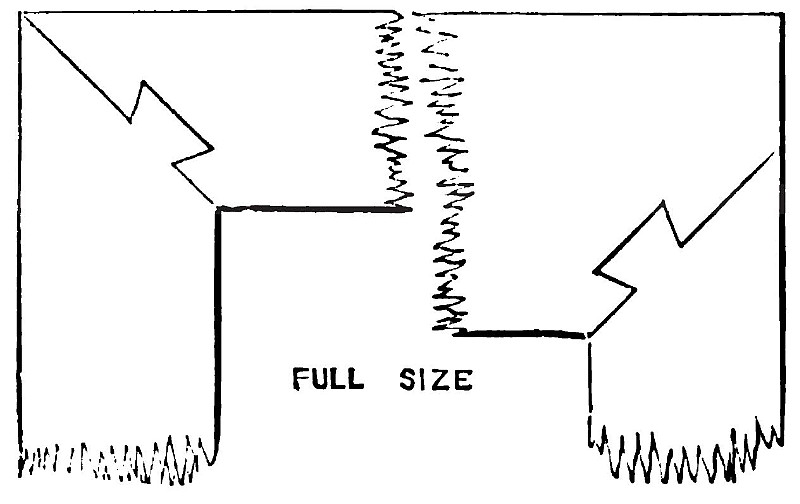

This machine, the invention of Messrs. William Furness and Co., wood working machinists, Liverpool, is for the purpose of cutting mitre or secut dovetails on timber used in the manufacture or drawers and other cabinet work, and is also applicable in all cases where the ordinary "1 pin" dovetail is used, the great advantage being that the work is much stronger, and the objectionable pin ends " arc done away with. It is entirely self-acting, and consists of a strong bed plate, on which stand the four upright carrying the cutter heads. The two fixed uprights have on the inside "V's in which slide a frame carrying the cutter heads for making the female end of the dovetail. These work in compound slides in the usual way by means of screws and are adjustable to the various thicknesses of timber used. They are set to the required angle and are driven by means of round leather bands, working in grooved pulleys, one of which, a friction pulley, is movable for the purpose of tightening the bands.

The two movable uprights are bolted to a slide frame, working in " V's " on the bed plate, by means of a screw and hand-wheel It can be moved to and fro to suit any length of timber, up to 4ft. 6in. long. On the inside of these also are "V's," in which slides a frame carrying the cutter heads for making the male end of the dovetail. The whole of this side of the machine can be moved to and fro by means of a screw and handwheel, to work any length of timber up to 4ft. 6in. long and 26in. wide, both ends being cut at once. The frames carrying the cutter heads on both sides of the machine can be lowered out of the way by means of a screw and handwheel, Ho that any length of timber can be worked by doing one end at a time. The table on which the timber is fastened works in slides, and is moved to and fro by means of screws actuated by bevel wheels. The timber is held firmly to the tables by pressure bars, an eccentric at the end of the lever giving the required pressure. This method of fastening the timber is at once firm and expeditious. There are three rates of feed, 6ft., 9ft., and 12ft. per minute/and a quick return motion for bringing back the table after the timber has been operated on.

The motion to and fro is communicated through a friction clutch, and stops are placed on the table for throwing it out of gear at the end of both the forward and return motion. |

|

1872 W.M.Furness & Co., Dovetailing Machine (Side View)

1872 W.M.Furness & Co., Dovetailing Machine (Side View)

1872 W.M.Furness & Co., Dovetailing Machine (Plan View)

1872 W.M.Furness & Co., Dovetailing Machine (Plan View)

1872 W.M.Furness & Co., Dovetailing Machine (Dovetail Joint)

1872 W.M.Furness & Co., Dovetailing Machine (Dovetail Joint)

|

|