|

Title: |

1889 Article-Charles P. Willard & Co., Vertical Engine & Boiler |

|

Source: |

American Engineer, V18, 24 Jul 1889, pg. 30 |

|

Insert Date: |

10/13/2018 1:04:21 PM |

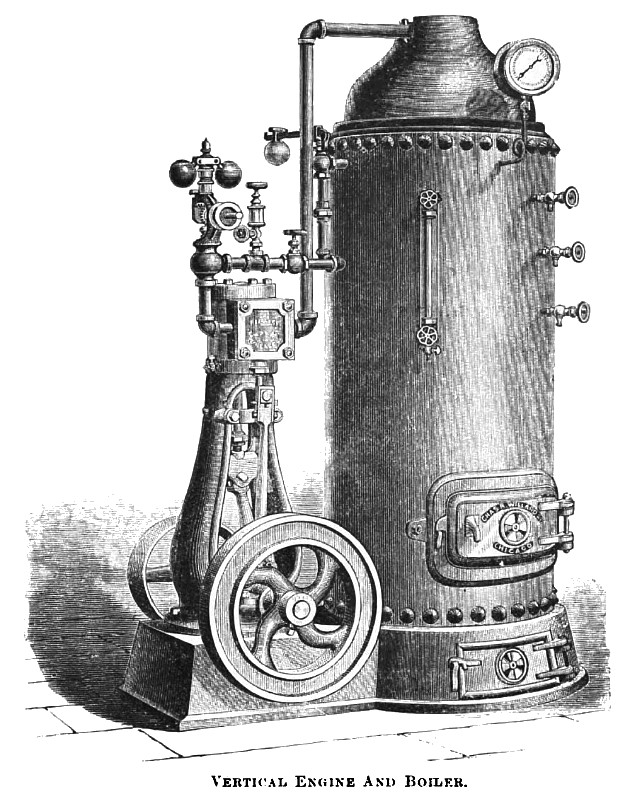

VERTICAL ENGINE AND BOILER.

The placing of engine and boiler on a single base proves to be very frequently, a most advantageous arrangement—one that is readily appreciated and adopted by manufacturers of light wares and goods, by farmers, printers and the owners of small work-shops. But to yield the highest efficiency, this type of engine and boiler has to be strong, rigid and compact with an abundance of steam; easily fired, oiled and packed, and readily adjusted and repaired.

The annexed engraving represents an engine and boiler on one base having all the desirable features we have named. The general exterior appearance of this combination appears pleasing to the eye. The excellent proportions and graceful form of frame, the absence of all bent pipes and distorted shapes, the completeness of fittings and withal its remarkable compactness—these make it one of the simplest and most desirable motors for a great variety of purposes. The manufacturers have named it the “Peerless” Engine, and have spared no pains to have it what the name implies, as the following reference to construction details will show. The piston rod, valve stem, and pins are made of steel. The crank shaft and connecting rod are made of Chester steel. The main frame of the engine and the slides, as well as the bearings for the crank shaft, are made in one piece, so that it is impossible for the working parts of the engine to get out of line or change their relation to each other. The construction of the engine is such that the action of the piston rod is exactly central, and all overhanging strains are avoided. These engines do not require any masonry foundation, or extra care in setting up. They will stand upon any ordinary floor and do perfect work, even when out of plumb. Every engine is adjusted, and run for several hours, before leaving the manufacturer’s works and is in complete order when sent out. A detached engine has many features which recommend it. When mounted on boilers, the journals often become so heated that it is difficult to keep them lubricated, and the working parts of the engine are liable to be thrown out of line by unequal expansion of the different parts of the boiler to which they are attached, and the durability and efficiency of the engine greatly lessened. A. Should it be necessary to move it any time, the boiler can be taken off the base by simply unscrewing the steam and exhaust pipes. A valuable feature of this form of portable boiler and engine is, that it can be taken apart and carried up or down stairs, or into localities where it would be difficult and expensive to carry the same power engines and boilers if all fastened together. Those familiar with the mechanical principles involved will understand why this form of engine. detached from boiler and standing on a solid iron foundation, is superior to the lightly constructed engines which are bolted to thin boiler shells. Aside from every other consideration. the greater power obtainable from an engine of this pattern, of same sized cylinder, owing to the higher rate of speed at which it can be run without serious vibration makes it a desirable motor. In a vertical engine no counter weight is required, because the recoil produced in a horizontal engine in overcoming the inertia of the reciprocating parts is here prevented by the perfect resistance of the earth, as the travel of the piston is in the direction of the line of gravitation and not across it. as with horizontal engines, and greater steadiness and freedom from vibration is obtained. In a vertical engine the wear is equal on all sides, which is not the case with a horizontal engine, in which there is always the heaviest wear on the underside of the cylinder. All bolts, nuts and screws used about these engines are of standard size and thread, and in case of emergency can be replaced at any good machine shop. All the parts are made to standard gauges and templates and are readily duplicated. Repairs are promptly made, and parts renewed with certainty of fitting.

Further information may be obtained from Charles P. Willard & Co., 236 Randolph Street, Chicago, Ill. |

|

1889 Charles P. Willard & Co., Vertical Engine & Boiler

1889 Charles P. Willard & Co., Vertical Engine & Boiler

|

|