|

Title: |

1908 Article-J. W. Mixter Saw Tool Co., Peerless Saw Gummer |

|

Source: |

Iron Age, V82, Aug 1908, pg. 546 |

|

Insert Date: |

11/24/2018 11:00:26 AM |

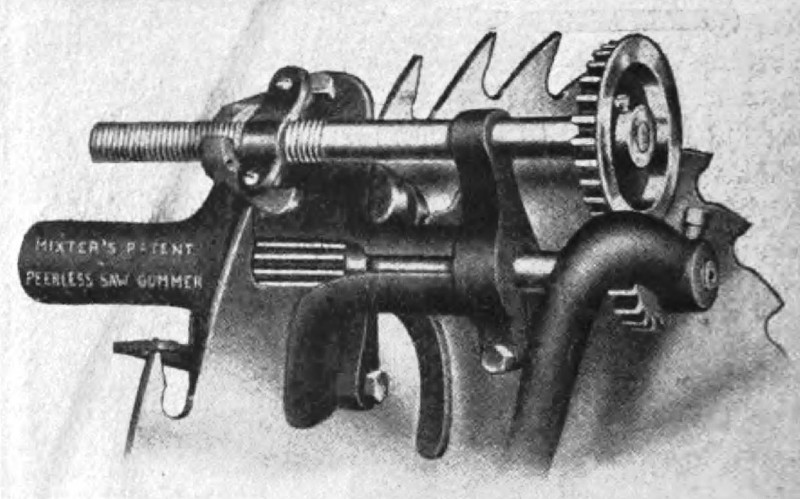

The saw gummer shown herewith is put on the market by the J. W. Mixter Saw Tool Company, Plymouth, Mass. It is referred to as a marked advance upon the company's Champion burr gummer and is said to retain all the advantages of burr gummers while obviating the disadvantages. Instead of feeding vertically into the gullet of the saw tooth, the feed is horizontal from the side. The gumming is done by a taper reamer cutter 4 in. long. It is the taper of this reamer, 9-32 in., which does the gumming. The reamer cutter is detachable from the cutter arbor, and therefore inexpensive, being made in sizes from 3/8 in. to 1 in. There are two bearing wheels or trolleys, one on the outer end of the reamer and one on the cutter arbor next the inner end of the reamer, which insures the entire absence of spring in the cutting part while the machine is at work. These bearing wheels are kept from revolving, and so wearing the main casting by means of lug pins which travel in slots provided for them. The arbor and cutter end turn in the bearing wheels. The chips of steel made by the gumming fall down through the slots and so do not interfere with. the wearing of the bearings. The machine is fastened to the saw by means of a cam lever and toggle, adjustable for the different thicknesses of saws, which is referred to as being far more easily and quickly done than with hand screws or thumb screws. There is a gauge, adjustable in two directions, for securing the proper position on the saw tooth and insuring that all the teeth will be gummed alike. The placing in position to gum at the proper angle is said to be much more easily accomplished than with the ordinary burr gummer. The drive of the feed is automatic and obtained from a threaded arbor, distinct from the cutter arbor, which works in a clutch nut. When the tooth is gummed the clutch nut disengages itself, and, being held open by the thumb and finger, the whole feed part and cutter arbor are quickly drawn back for another operation. There is a flange on the outer side of the gear on the feed arbor which forces the reamer cutter into the gullet of the tooth. The crank is attachable in two places to the small arbor gear by a clutch, thus saving key pins, and to the arbor itself by a set screw, so that it can be readily used at full length or shortened for quick work on thin saws. The bearing for the cutter arbor is slotted and has a bolt for tightening which admits of taking up the play as it wears.

There is nothing in the gummer, it is explained, that will wear out by constant use, except the reamer cutter, and that, it is pointed out, is much more durable than an old style burr, as the reamer cuts with a shearing cut and the teeth cannot chip off by turning backward or from taking hold unevenly. Also, the whole of the reamer cutter is used automatically in each operation and no care has to be taken to oscillate from side to side, as with the old-style burrs. The chief distinctive features of the gummer, as enumerated by the manufacturer, are the detachable reamer cutter, the cam lever and toggle device for quick attachment to the saw, and the durability of all parts and resulting cheapness of maintenance. |

|

1908 J. W. Mixter Saw Tool Co., Peerless Saw Gummer

1908 J. W. Mixter Saw Tool Co., Peerless Saw Gummer

|

|