|

Title: |

1912 Ad & Article-Kane Mfg. Co., Inc., Drag Saw Gummer & Sharpener & Saw Set |

|

Source: |

The Timberman, V13, Jun 1912, pg. 46 & 48 |

|

Insert Date: |

11/26/2018 8:27:36 PM |

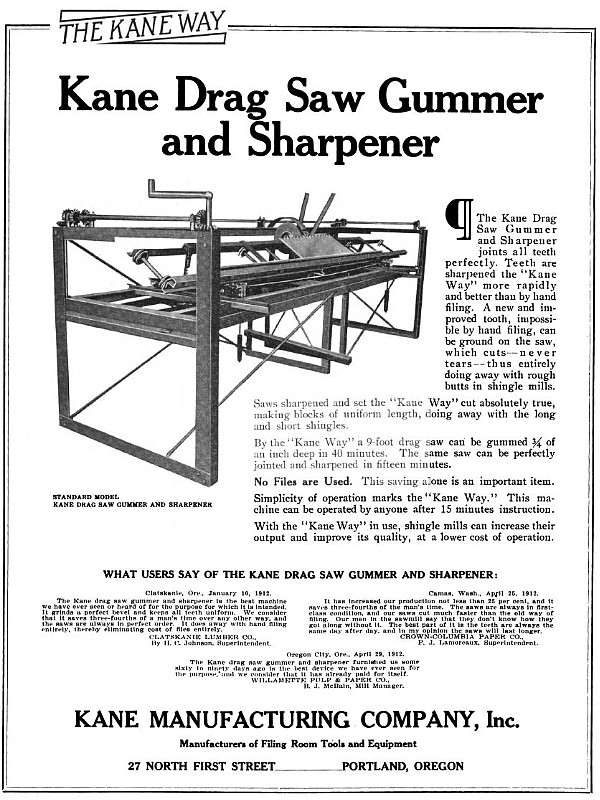

The Kane Manufacturing Co.. of Portland, Ore.. Is manufacturing the Kane Drag Saw Gummer and Sharpener, a machine for gumming and sharpening drags and crosscut saws, especially adapted for drag saws in shingle mills, pulp mills and veneer factories.

In speaking of the advantages of the machine Charles Kane, the inventor, says: "By the 'Kane way' saws are always in better condition than when gummed and filed by hand. The teeth are always perfectly jointed. Saws gummed and filed the 'Kane way' always cut absolutely true. They will never 'run.' thus doing away with long and short shingles. An improved tooth can be put on a saw by this machine, impossible with hand filing, which will always cut and never tear, thus doing away with rough butts entirely.

"Saws cared for the 'Kane way' will cut more rapidly and increase the output of a pulp mill 20 to 30 per cent, and the average shingle mill from 5 to 10 per cent. In most shingle mills the drag saw is usually behind the other departments. With a greater production of material at this end of the mill the entire output in accordingly increased.

"The purchase of files, a very considerable item of expense, is entirely dispensed with. The time of the filer is reduced three-quarters as compared with hand filing. The machine can be operated with equally good results by anyone with or without experience at saw-filing, as all the work done is entirely mechanical. Less power is required to operate the saws because of the perfectly jointed teeth. The Kane way' lengthens the life of the saws by removing unnecessary strain upon them when cutting.

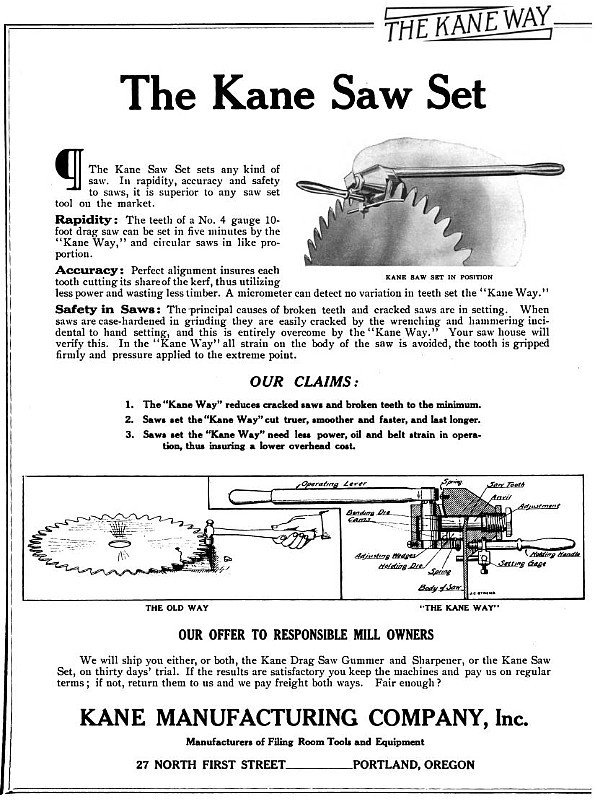

We also manufacture a filing-room tool known as the Kane Saw Set, which sets all kinds of saws, which will set a ten-foot No. 4 gauge drag saw perfectly in five minutes. By its accuracy a less clearance is required to the saw than hand-setting, effecting a saving in timber. Perfect aligned teeth require less power to operate than when the set is more or less irregular. There Is also a saving in oil and belts by reason of less strain and friction.

"Pressure, in setting with this machine, is only exerted on the extreme point of the tooth, thus preventing all strain on the body of the saw. Most cracks in saws originate at the point where the saw has become case-hardened from gumming and is caused by hammering the tooth in setting. Saws are also often broken by grabbing a slab, owing to the irregular set of teeth, an accident which is often attended with injury to workmen."

Charles Kane, the inventor and patentee of the "Kane way," is an experienced mill man. as well as a skilled saw filer, possessing just such knowledge as Is required to develop practical mill machinery. |

|

1912 Kane Mfg. Co., Inc., Drag Saw Gummer & Sharpener

1912 Kane Mfg. Co., Inc., Drag Saw Gummer & Sharpener

1912 Kane Mfg. Co., Inc., -Kane Saw Set

1912 Kane Mfg. Co., Inc., -Kane Saw Set

|

|