|

Title: |

1887 Article-New York Belting and Packing Co. Saw Gumming Emery Wheel |

|

Source: |

Scientific American, V56, 26 Feb 1887, pg. 130 |

|

Insert Date: |

12/6/2018 11:49:14 AM |

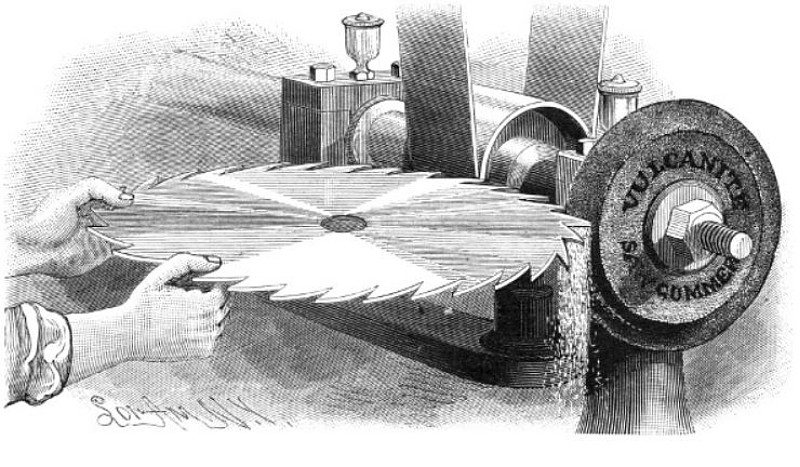

EMERY WHEELS FOR GUMMING SAWS.

In the illustration herewith, the operation of gumming saws with an emery wheel is vividly represented, the frame affording sufficient support for the side of the saw where the teeth are being ground, and the arrangement being a simple one, readily made at any work bench or machine where a shaft is run upon which an emery wheel can be placed. The operation itself involves only the simplest mechanical knowledge and but a rudimentary experience in the handling of tools, yet the desirability of this method of sharpening saws is largely dependent upon the kind of emery wheel used and the rate of speed at which it is run.

The vulcanite emery wheels made by the New York Belting and Packing Company have especial advantages for this kind of work. They are strong and safe at the highest speed at which it is desirable to run them, the company recommending that they never be run at a less rate than 6,000 feet per minute circumferential speed, and from that up to 8,000 and 10,000 feet per minute, although the lowest named speed is rather above the ordinary limit of many other kinds of emery wheels, and attempts to run other wheels at or beyond this limit have frequently resulted in serious accidents, from the breaking of the wheels. The higher rate of speed, which not only cuts faster, but, in the case of the vulcanite emery wheel, prolongs the life of the wheel, is concededly safe with the vulcanite wheel. Thus run, it is not likely to wear out of true, the operator does not have to bear on so hard, and the wheel retains its shape much better than when run at a slow speed. The nature of the wear of the working surface in the vulcanite wheel is claimed to be essentially different from that in wheels where the emery is fixed in its place by other methods, the rubber affording an elastic foundation or cushion, from which the particles of emery slightly protrude. This not only insures more efficient work from the cutting edges of the emery, as they become changed by use, but allows of more access of air to the work, thus tending to prevent casehardening of the edges of the metal being ground.

In addition to wheels with bevel shaped grinding surfaces, as represented in the engraving, the company also make wheels with round grinding surfaces, and this kind is always considered best for large saws. |

|

1887 New York Belting and Packing Co. Saw Gumming Emery Wheel

1887 New York Belting and Packing Co. Saw Gumming Emery Wheel

|

|