|

Title: |

1900 Article-Cairo Foundry & Machine Shops, Hoo-Hoo Gummer & Sharpener |

|

Source: |

Age of Steel, V88, 25 Aug 1900, pg. 25 |

|

Insert Date: |

12/6/2018 8:19:25 PM |

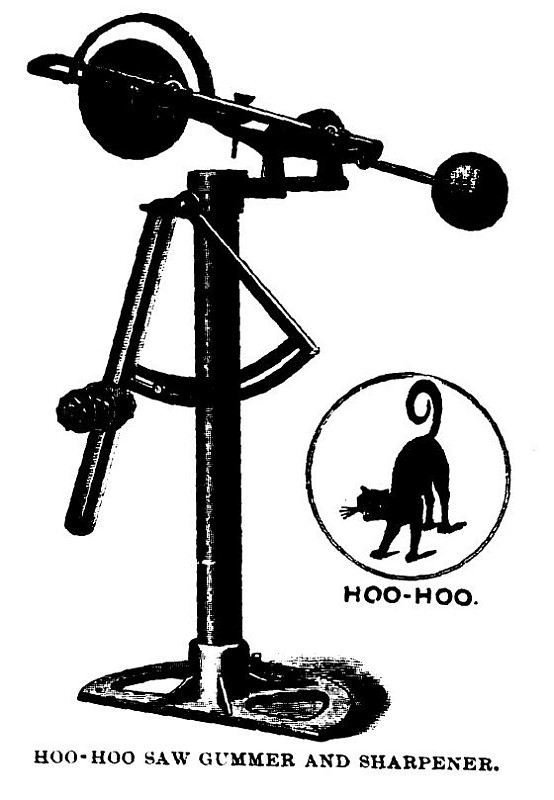

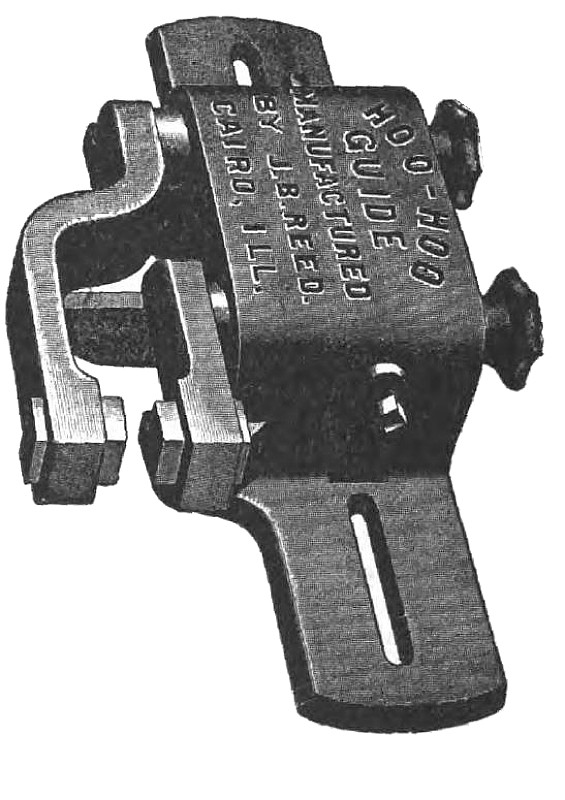

We are pleased to illustrate herewith the Hoo-Hoo saw gummer and sharpener, manufactured by the Cairo Foundry and Machine Shops, Joseph B. Reed, proprietor, Cairo, Ill.

This machine is made from new and improved patterns, combining all the latest and best improvements and is accurately and substantially built. The weight is about 375 pounds. It has refined steel shafts, with large collar. Long and adjustable bearing: has adjustable stop to regulate the depth and shape of tooth. It is easily adjusted to any size saw up to 74, for rip or cross-cut, square or cut under to any degree and any shaped tooth or distance between the teeth; has two changes of speed, is compact and occupies but a small space on the floor. The dimensions of the tight and loose pulley on the driving shaft, 4 inches diameter, 2½ inch face; speed about 1,000 revolutions per minute. The machine will save much time and keep saws in much better shape than any other way of sharpening them. In fact, it will save its cost in files alone in a very short time. The low price brings it within the reach of the smallest users of circular saws, and no one can afford to be without it. Every firm that has used them speak of their superiority over other gummers. The machine is furnished as shown in cut, without emery wheel. Supported by heavy base, with wrought hollow columns. Sold to responsible parties on, thirty days’ trial, fully guaranteed to give entire satisfaction, or be returned at the manufacturer’s expense. The adjustable Hoo-Hoo saw guide, which we show here with, is adapted to both right and left-hand mills. It is a first-class guide in every respect, simple in construction, and so arranged that the adjustment can be quickly made with perfect safety to the operator. The adjustments are made by turning the hand wheels, by which either jaw can be moved independent of the other. The jaws are turned so as to make a neat fit in the bearings and move parallel to the surface of the saw. The jaws can be turned back to permit the removal of the saw without displacing the guide. The guide pins are made square and filled with best oak tanned leather, well saturated with oil. In the construction of the Hoo-Hoo saw guide nothing but the best of material is used, and most expert mechanics are employed. Warranted to give entire satisfaction or can be returned at manufacturer’s expense. |

|

1900 Cairo Foundry & Machine Shops, Hoo-Hoo Gummer & Sharpener

1900 Cairo Foundry & Machine Shops, Hoo-Hoo Gummer & Sharpener

1900 Cairo Foundry & Machine Shops, Hoo-Hoo Gummer Guide

1900 Cairo Foundry & Machine Shops, Hoo-Hoo Gummer Guide

|

|