|

Title: |

1893 Article-Vulcan Co., Curved Molding Machine |

|

Source: |

Metal Magazine, V2, 08 Jun 1893, pg. 384 |

|

Insert Date: |

2/6/2019 1:31:59 PM |

|

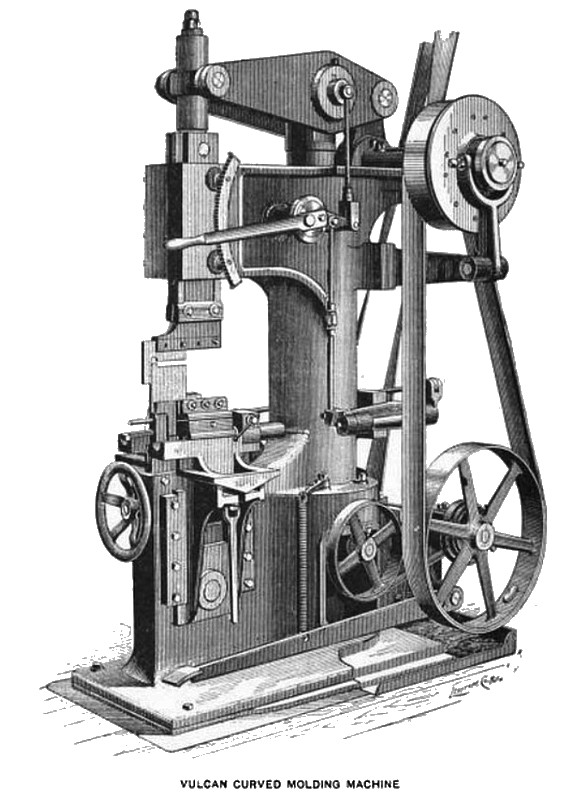

The Vulcan Company, 1227 Callowhill Street, Philadelphia, are putting on the market, with other patented devices, a machine, which has hitherto given the members of the Vulcan Company a practical monopoly of the curved molding business in their several districts. The machine is illustrated in Fig. 1. It is hardly possible for a mechanic, on first examining it, to conceive of the scope of work, which it can produce wait an ease and facility that seems almost like magic. It is not only far in excess of the power of any ordinary machine for making curved moldings, but its capacity for small moldings is something that cannot be approached with any other machine or tool now manufactured and its range of work is almost unlimited. It will form complete circular moldings of three- or five-inch profile down to two inches in diameter and will make spheres from six inches to six feet in diameter, in sectors or segments. By simply changing the tools, it will form molded faces of brackets which are ordinarily stamped. It is an embossing machine, in other words, a hand hammer with its scope indefinitely widened by the ability to strike repeatedly in the same place with the same amount of force and widened again in another direction by the ability to use a hammer with a long face of irregular profile. Instead of expensive rolls to make where it is desired to change a pattern it is only necessary to put in a pair of dies, such as are shown in Fig. 1. These can be made to any profile in a few minutes from zinc, lead or solder, and cost but a few cents per pair. When done with them, they can be melted for new sets. They are so simple that even when made of cast iron their cost is too trifling to become an item in cost. Although the machines have been in use for several years, scarcely a week passes without a surprise in the way of some new achievement from a skillful workman. Repoussé patterns on large sheets are produced with a facility and accuracy which leads many who are familiar with the machine to the belief that when its capabilities have been fully explored, and all modifications achieved, that work which is now considered artistic, and is left for the hand, can be executed on the machine. Whether the machine is used for ordinary routine work or is employed to carry out architect's special designs it has a range and a facility which makes it invaluable, and it will become indispensable in the future wherever its power is known. In general, it can take the place of hand hammer work. It is heavy and powerful and runs at the rate of 600 strokes a minute. A little examination of Fig. 1 will show that the numerous adjustments for holding the dies, controlling the length of the stroke and the speed, are all provided for by means of a foot and hand lever, and hand wheel at the front, and that the different adjustments are under the complete control of the operator. The cuts are from an elaborate catalogue recently published by the Vulcan Company. |

|

1893 Vulcan Co., Curved Molding Machine

1893 Vulcan Co., Curved Molding Machine

|

|