|

Title: |

1922 Article-Blacker Engineering Co., Blacker Smithing Hammer |

|

Source: |

American Machine & Tool Record, V22, Dec 1922, pg. 58 |

|

Insert Date: |

3/31/2019 2:17:23 PM |

THE BLACKER SMITHING HAMMER

Practical craftsmen have long felt the need for a power hammer capable of replacing the hand swung sledge upon jobs that cannot be properly, nor economically, handled upon even the lightest of steam hammers.

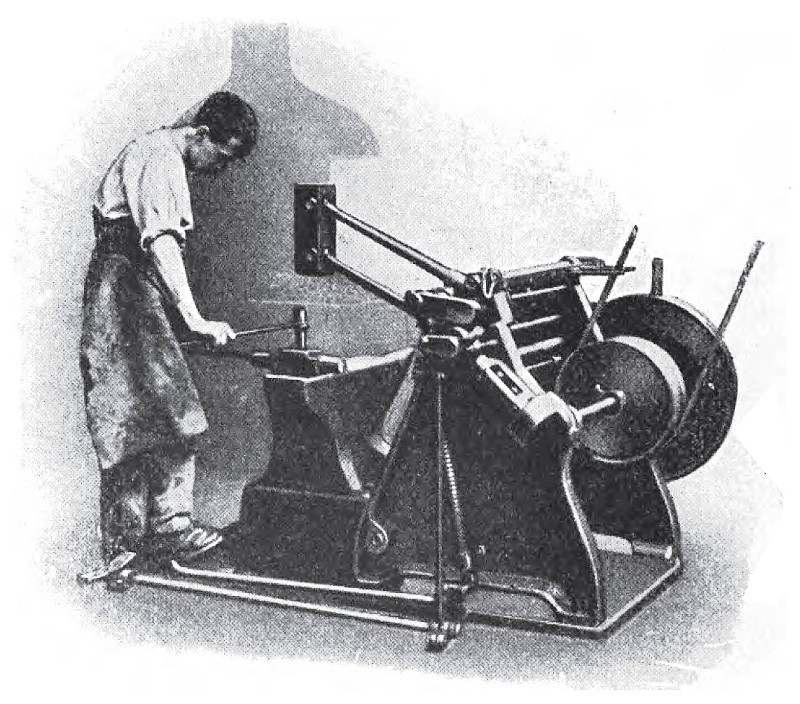

Numerous attempts have been made to supply such requirements, but with questionable success. The Blacker Engineering Co., Inc., Grand Central Terminal, New York City, recognizing the demand for a machine that would successfully replace the hand swung sledge, is marketing the Smithing hammer illustrated herewith. This, unlike other hammers, is not limited to special work, nor does it require any special tools or dies.

It is essentially a “Mechanical Helper,” replacing one or two human strikers, who are, for the amount of actual work they do, very highly paid. Blacker hammers use the same hand tools to which the Smith is accustomed, are always ready for work, and much more efficient and powerful than human strikers.

The old primitive hand anvil is found in all shops, even alongside the most modern power hammers, and it cannot be dispensed with, but one can dispense with the helpers, and at the same time greatly increase the anvil's capacity and output.

This Smithing hammer was developed and perfected by a practical smith, for his individual use as one-man tool. Operations can be completed with it three to four times more rapidly than by the old-fashioned hand methods, and while the machine is rated for 2%-in. material, it will handle larger sizes as needed. The hammer is always under perfect control and the operator can at will strike light or heavy blows, intermingled or not as desired. The force of the blow varies directly with the depression of the foot treadle that extends around the anvil.

The maximum blow is about four times as heavy as that of a human striker and the machine attains the rate of 140 blows per minute. This is almost four times the human speed and the limit of speed at which the Smith can handle his tools. The usual distance between the head and the anvil is 8% ins., but the stroke can be adjusted in a moment to suit the work in hand.

The lateral traverse motion is an important feature. It is controlled by a winged foot lever conveniently located to the right of the anvil, permitting the head to be instantly traveled along the face of the anvil to any desired point. Thus, the head is brought exactly over the holes, and ready for swaging, punching, heading, and similar work.

The parallel arms are so adjusted that the work is always struck a flat, straight blow, doing away with the clamps, swages, and special tools usually required with other hammers. The movement of the head is very similar to that of the hand swung sledge, and raises to strike its blow, then rebounding quickly from the metal.

With greater power, rapidity and accuracy of hammer blows considerably more can be accomplished at one heat, and the saving over obsolete hand methods is visibly evident. Not only can costs on small production work, on tool dressing and sharpening be cut one-half, but a better forging is obtained.

An anvil and block of special design is furnished, built to specifications. This has a planed base and a stand with adjusting screws, as shown in the illustration. This adjustment permits of the anvil being brought backward or forward as required, and its use materially increases the efficiency of the machine.

The tight and loose pulleys are 15 ins. in dia. by 2¾,-in. face. The hammer requires but one horsepower to drive, and on a line shaft with other tools the power absorbed averages much less. A belt approximately 7 ft. in length is required. At a recent demonstration attended by inspectors from various parts of the country, representing many of the larger railroad and industrial companies, operations were performed as follows, and the work completed in one hour that ordinarily required a “smithing gang” one-half day, all the work being done by a single operator without the aid of “strikers.” For example: (1) and as showing the utility of the hammer, for the making of smithing tools, a piece of mild steel 2½ ins. square was heated, the operator then drawing down a shank cut off a piece from the bar, fitted it to the hardie hole, and at one heat made a steel bottom swage suitable for swaging 1-in. round material.

(2) A bar of 1 1/8-in. round steel was properly heated and drawn down to make the leg of a pair of tongs. This was perfectly made, with nicely reduced shoulders, the hole was punched for the rivet and the end cut off, all at one heat.

(3) Without the aid of any tools a piece of 2½-ins. square was brought down to a very fine point at one heat, showing the perfect control of the blows and demonstrating the usefulness of the machine for dressing chisels, picks, and other articles with tapered ends.

(4) He next made a 2-in. welded nut, 3 1/8-ins. across the flats. This was made from 2 by 7/8-in. wrought iron, a piece being cut off hot. the ends tapered in cutting and the whole being bent into position at the first heat. It was thoroughly welded and perfectly finished in the second.

(5) A bolt was then made from 2-in. square iron, 6 ins. long and 1½ ins. in diameter, with a square head and neck. The material was forged, swaged, cut off, headed, and finished at one heat, and was illustrative of the adaptability of the machine for the different operations required.

(6)_Two 3-ft. lengths of 1½-in. round mild steel were welded into a single bar. The two ends were scarfed and prepared then heated and perfectly welded together. Without any aid this work was very efficiently done, the piecing nicely swaged and finished without marks or edges showing.

A lateral traverse motion is provided and is an important feature since it enables the head to be instantly traveled along the face of the anvil to any point, and brought perfectly over the holes, being then ready for swaging, punching, heading, or other similar work. This motion is controlled by a winged foot lever conveniently located to the right of the anvil and can easily be operated without stopping the hammer. In large shops, using other types of special hammers, the Blacker hammer has proven especially efficient for quick general utility work. In fac it is a general smithing hammer with such distinctive features of construction as to make it an extremely useful and economical tool.

The company is also marketing this Smithing hammer operated with an electric motor. The motor is of 1 horsepower rating and is mounted in the base of the machine, and geared to a large driving gear, in place of the tight and loose pulleys, making a most compact unit. |

|

1922 Blacker Engineering Co., Blacker Smithing Hammer

1922 Blacker Engineering Co., Blacker Smithing Hammer

|

|