|

Title: |

1886 Article-S. E. Smith & Bro., Wood Lathe for Turning Square Work |

|

Source: |

Manufacture & Builder, V18, Feb 1886, pg. 30 |

|

Insert Date: |

11/6/2019 1:01:27 PM |

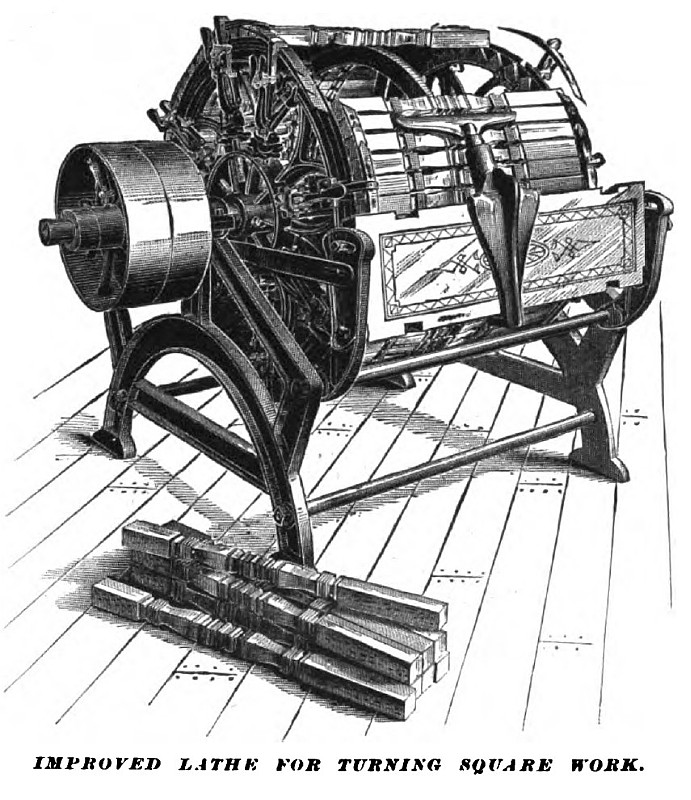

Improved Lathe for Turning Square Work.

The accompanying engraving represents a machine for which the manufacturers claim several new and important features found in no other square-turning lathe, and which makes it capable of doing first-class work very rapidly. It is easily and quickly adjustable to suit any size of work, is simple in design and construction, and a first-class machine at a very moderate price. Its points of superiority will appear from the following description of its construction and operation:

Journaled in suitable boxes on the frame of the machine is a shaft having tight and loose pulleys on the outer end. Mounted upon this shaft are two heads, or wheels, adjustable to any position thereon to enable them to hold materials of any length. The materials to be turned are held on the wheels by a series of clamps or shoes, arranged around the circumference of the wheels, and adjustable toward the center thereof by means of a screw and nut, to enable them to clamp to the wheels materials of any thickness. Besides this radial movement, the shoes have also a lateral movement, so that they may be set sidewise from the face of the wheels to freely permit of placing materials thereon.

Having been adjusted to the thickness of the materials by means of the screw and nut, the shoes are afterwards operated by a quick-moving and powerful lever. A single backward movement of this level will release the shoe from the work, when a spring instantly sets it sidewise out of the way, as shown in the engraving. When this section of the wheels has been filled with materials or when they have been turned over, the shoe is brought back over the ends of the work, when a single movement of the lever will firmly clamp them to the wheels, and at the same time securely lock the shoe and lever so that the shoe cannot be thrown off from the work except at the will of the operator.

As the sections are filled with materials, they are securely clamped so that they cannot be afterwards displaced in filling the balance of the wheels. When the wheels have been completely filled with materials, they will form a cylinder, which, being revolved, the outer face of the materials can be quickly cut to any desired shape by means of common turning tools. This done, the pieces are turned over and the other sides cut in like manner. A good turner will cut all the sides alike without any trouble. The pieces can be easily and quickly turned over, as only one section at a time need be freed from the shoes, while all the others remain securely clamped to the wheels. Each wheel has a guide against which the ends of the materials are placed, so that the lateral alignment of all the pieces with relation to each other, when they are turned about, is insured with ease and certainly. The wheels are also provided with adjustable angular seats, by means of which the work may be made octagonal, or with any desired number of sides.

In turning pieces of small diameter and considerable length, they will spring and chatter under the action of the cutting tools, thereby making rough work. To avoid this, the makers have provided a middle support for such work, upon which the pieces are firmly bound by an adjustable bund, thereby preventing all vibration and permitting of the finest work. This band can be adjusted to any size of materials, and can be instantly unclasped from the work and hooked up out of the way. The middle wheel is provided with an expanding arrangement by means of which it can be set out snug against the work, where it rests upon it, in case it should be cut smaller than the original size.

The shoes which hold the material on the wheels are made of the best spring steel, and readily adjust themselves to any size of materials. They are made to a radius somewhat smaller than the wheels, so that when placed upon the work they will touch first at the extreme ends, and when the middle portion is sprung down to the work by means of the lever they will grasp all the materials under them very firmly. The lever is made in such a manner that the middle joint thereof goes a little past the center when the lever is raised into position to bring the shoe down to the work, thereby tending to hold the lever and shoe firmly in place; but, as a further security, each lever is provided with a strong steel catch, so that it is impossible for the shoes to become displaced from the work and allow it to fly off the wheels. The bars to which the shoes are attached, the levers, and all parts of the mechanism that secure and operate the shoes, are made of steel, have solid and substantial bearings, and are made heavy and strong, so that there is no danger of their breaking or getting out of order.

The bed piece in front of the machine which sustains the tool rest is made of thick hardwood plank and is very firm and substantial. It is readily adjustable to or from the work by loosening a single nut at either end of the bed. The rest holder is planed true on the underside, so that it rests solidly on the bed, and is provided with a strong shoulder on the back side at the lower end, so that the tool rest shall not tip and come in contact with the revolving work.

The machine throughout is simple in construction, strong and durable, and with reasonably careful usage should run for years without needing repairs. It is well balanced, runs true and steady, requiring the minimum of power for its capacity. The makers claim for this machine that it will do four to eight times more work than a common lathe, and finish the work perfectly smooth, with all the edges clear and sharp, and that it will execute the most delicate patterns of work, and make all the moldings, fillets, quirks and arrises deep, clear, sharp and smooth.

US Patent: 321,763

http://datamp.org/patents/displayPatent.php?number=321763&typeCode=0 |

|

1886 S. E. Smith & Bro., Wood Lathe for Turning Square Work

1886 S. E. Smith & Bro., Wood Lathe for Turning Square Work

|

|