|

Title: |

1886 Article-C. B. Rogers & Co., 10 inch Inside Molder |

|

Source: |

Manufacture & Builder, V18, Mar 1886, pg. 53 |

|

Insert Date: |

11/7/2019 10:49:19 AM |

Improved Inside Molder.

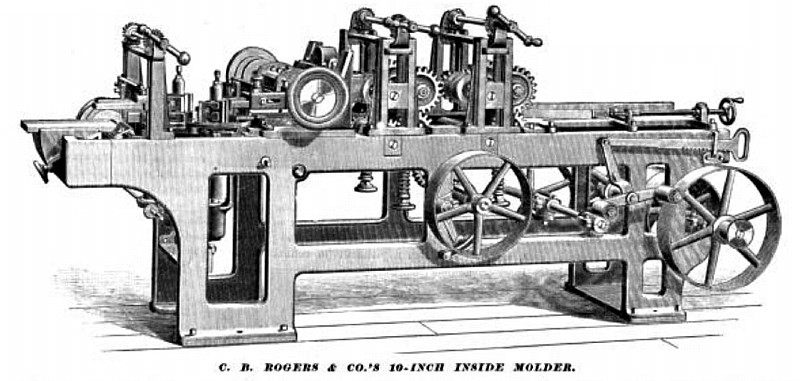

The illustration herewith shown exhibits the new 10-inch inside molder of the well-known manufacturers of wood-working machinery, Messrs. C. R. Rogers & Co., of Norwich, Conn., and 109 Liberty street, this city. It differs in several important respects from the other molders of the same makers, the changes introduced being such as to add to the convenience of operating the machine, and lo its general efficiency. The principal mechanical details will be understood from the following description.

The machine is arranged to work 10 inches wide and 6 inches thick, with all necessary adjustments for slicking moldings of every style, also flooring and ceiling. The top and bottom cylinders are made from solid crucible steel forgings, head and journals in one piece, and are slotted on four sides; the pulleys arc provided with a huge flange which acts both as a balance wheel to carry the cylinder through a heavy cut, and as a convenient means of turning the cylinder when setting the cutters. The top cylinder is adjustable endwise across the machine, making a great saving of time in selling the molding cutters; the lower cylinder is raised and lowered to any desired position in the same manner as the top one. Boxes for both top and bottom heads are connected in yoke form to avoid any cramping. The side spindles are moved to any desired position across the bed by means of screws, and both spindles can be tipped to work at an angle. All bonnets, chip breakers and pressure bars are arranged lo swing clear of the cutters in the heaviest work, and may be thrown back, or removed entirely, when setting or sharpening the knives. The opening in the bed for the lower cylinder may be enlarged or diminished at pleasure, and the entire end of the frame can be swung off to one side, giving free access to the lower cylinder. The feed is very powerful; the rolls arc geared at both ends, and the feed roll shafts so arranged that wide rolls can be removed and narrow or spur rolls substituted without loss of lime. The feed may be set at any desired speed.

The tight and loose pulleys on the counter-shaft are 10” x 6”, and should make 1,000 revolutions per minute. |

|

1886 C. B. Rogers & Co., 10 inch Inside Molder

1886 C. B. Rogers & Co., 10 inch Inside Molder

|

|