|

Title: |

1886 Article-W. F. & John Barnes Co., Upright Drill Press |

|

Source: |

Manufacture & Builder, V18, Mar 1886, pg. 52 |

|

Insert Date: |

11/7/2019 11:15:30 AM |

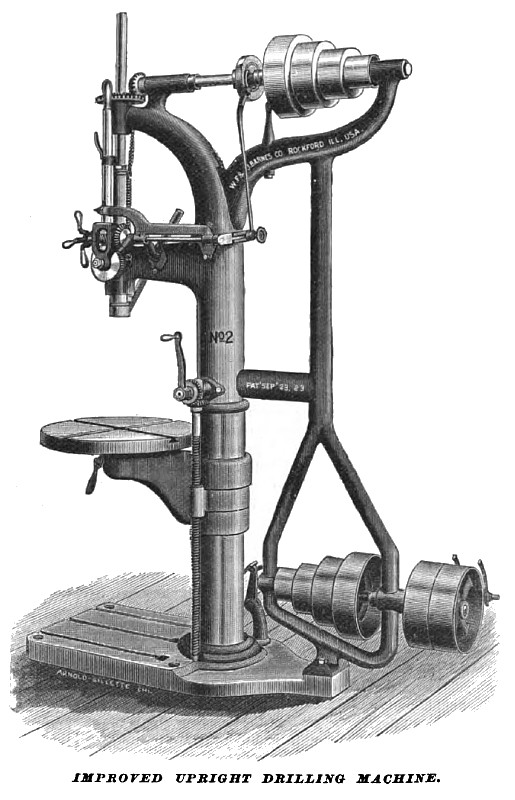

Barnes Improved Upright Drill

The accompanying illustration exhibits an upright drilling machine, in which the makers have succeeded in combining a number of features which adapt it for a great range of work. It embraces an arrangement of parts whereby either a lever feed, hand screw feed, or automatic power feed is provided, each being complete in itself, and capable of being used independently of the others, so that, for example, the lever may be used for small drills, the screw for larger drills, and the power feed for either. The design of the machine is such as to fill the requirements of any one of the above named features as completely as though it had been built with especial reference to only one of these, and the operator can bring either form of feed into use instantly without interference with the others. The essential details will appear from the following description:

The back gear is of the internal, or planetary pattern, combining great power and compactness with durability and comparatively noiseless action. It is brought into action or thrown out by raising or lowering a latch which projects from the face plate of the cone pulley. This latch is easy of access and can be instantly operated. The automatic feed is affected by the use of an eccentric, located on the upper horizontal cone pulley shaft, which in turn, by means of a pawl and ratchet, operates the. screw, worm wheel, rack and pinion, and sleeve in which revolves the spindle that carries the drill or cutters. By the suitable adjustment of the rod in a slot provided in the rocker shaft arm, which may be instantly done while the machine is in motion, any desired speed of feed may be obtained. The screw that engages the worm wheel is located in the feed lever and is provided with the usual hand wheel for screw feed. This screw can be raised from the worm wheel by a thumb latch above on the feed lever. This screw operates as a screw or pawl and is operated as a pawl by the thumb latch above it in the feed lever.

It will thus be seen that the design of the machine provides lever, screw and self-feeds, as each maybe required by the work in hand, and that each of these may be used independently of the others.

The quick return is obtained by raising the screw from the worm wheel by means of the aforesaid thumb latch, when the lever on the opposite side of the machine can be used to raise or lower the drill spindle rapidly. The platen is so contrived as to be adjustable in height by means of a screw placed parallel with the column and operated by a handle within easy reach of the operator. By this device the workman standing alongside the machine can readily raise or lower the platen to any desired height on the column, thus dispensing with the pile of blocks and wedges commonly used as a substitute. The platen also turns in the arm that supports it and may be thrown out from under the drill spindle by swinging the arm on the column. Both platen and its supporting arm can be clamped firmly in place by clamping screws that have levers attached to them, thus avoiding the necessity of using wrenches or detached tools in making necessary adjustments.

The drill spindle is of steel, lilted with the Morse twist drill taper, and counterbalanced by a weight in the hollow of the column. The rack and pinion for feeding the spindle are cut from solid Norway iron. The bevel gearing is also cut from solid iron and is comparatively noiseless in operation. The bearings are long and well fitted, to insure long wear. The shipper is located conveniently to permit the operator to start and stop the machine easily with his foot. The cones are designed for a 3-inch belt, and have four changes of speed, giving a great range of speed. The machine will drill to the center of a 25-inch circle. It has the following dimensions:

Height of the drill, 6 feet 6 inches: diameter of column, 6½-inches; diameter of spindle, 1½-inches; vertical travel of spindle, 14¾-inches; diameter of large pulley on cone, 10-inches; diameter of small pulley on cone, 4-inches; diameter of fast and loose pulley, 10-inches; diameter of bevel wheel, 7-inches; diameter of bevel pinion, 3½-inches; distance from spindle to base, 3-feet 8¼-inches; weight, 1,000 pounds.

The makers are the W. F. & John Barnes Company, of 67 Ruby Street, Rockford, Ill. |

|

1886 W. F. & John Barnes Co., Upright Drill Press

1886 W. F. & John Barnes Co., Upright Drill Press

|

|