|

Title: |

1919 Article-Baker Iron Works-Alligator Shear & Marine Engine Castings |

|

Source: |

Iron Age, V103, 13 Mar 1919, pg. 736 |

|

Insert Date: |

2/21/2020 9:28:16 PM |

Expansion of Baker Iron Works in Keeping With Rapid Growth of Los Angeles

The close interrelation between a live community and an efficient industrial organization growing up in its midst could hardly find a better illustration than in the case of the city of Los Angeles, Cal., and the Baker Iron Works. In 1872, when the works was started, the needs of the inhabitants were mostly agricultural, and the plant made plows and farm implements and ran a jobbing foundry and machine shop. With a rapid increase in the population came the need of improved means of local transportation, and the company enlarged its facilities to make street cars, employing a force of about 100 men.

Then came the oil boom and its urgent and pressing demand for the highly specialized tools and equipment for well drilling. Eleven steam hammers were added to the equipment giving constant employment to 300 men. The works escaped the dangers of over specialization, as the panic of 1907 put a quietus on further activity in the development of Southern California oil resources but did not arrest the progress of California nor interrupt the rebuilding of San Francisco.

In the reconstruction the reinforced concrete office building found extensive application, and in their operation highspeed elevators were essential. Utilizing its experience gained as agent of the Otis Elevator Co., the Baker Iron Works not only furnished and equipped complete but for the electric motors, high power passenger and freight elevators but undertook also the fabrication and erection of the steel frames for this type of building construction.

It also designed and fabricated a special riveted steel pipe 7 ft. in diameter with 1-in. walls, used extensively in the new 260-mile Los Angeles aqueduct, and in irrigation work, running all the way from 10 gage (9/64 in.) to 16 gage (1/16 in.).

In the four years preceding the war the company completed and installed 50 overhead travelling cranes in Southern California and South America, the largest of which, now in the plant of the Southern California. Iron & Steel Co., Los Angeles, is operating with five motors over a span of 60 ft. with a lifting capacity of 50 tons.

Its boiler shop meantime was turning out equipment for sugar works and chemical plants. A problem of peculiar local importance successfully solved was the design and installation of apparatus for the production of gas from crude oil by distillation. This product, mixed with coal gas, is extensively used for lighting and heating purposes and means a great saving to the consumer through elimination of transportation charges on coal and coke from distant centers of production.

The city, through the development of San Pedro harbor and by connecting it with the city through the acquisition of the so-called “Shoe-string” strip, more lately consolidated its position as an important factor in the Pacific marine trade. This growth was brought to rapid maturity by the outbreak of the war.

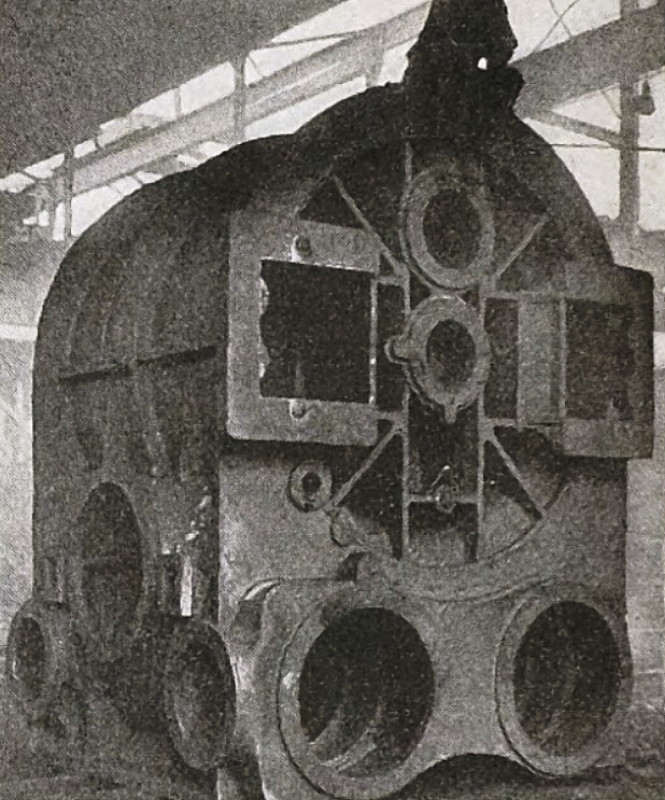

To meet shipbuilding demands a gray iron foundry was installed, with facilities for producing the large castings required for marine construction (between 15 and 22 ton) at the rate of up to 75 tons per day. A notable performance in its machine shop department has been the finishing of what is reported to be the heaviest so far cast on the Pacific Coast. It was poured at the Columbia Steel Co., Pittsburg, Cal., and forms the base of an alligator shear. The preparation of the local scrap for open-hearth operation exposes such tools, designed for cutting 6 x 6 in. bars in the cold, to exceptional strains which the original cast-iron base of the machine Was found incapable of withstanding. The new casting measures 25 ft. long x 8 ft. wide x 8 ft. high at the highest point. It weighs about 58,000 lb., and the cutting blade, which will be electrically operated, will weigh over 10 tons. |

|

1919 Baker Iron Works-Alligator Shear & Marine Engine Castings

1919 Baker Iron Works-Alligator Shear & Marine Engine Castings

|

|