|

Title: |

1911 Article-Cincinnati Bickford Tool Co., 21 in. Verical Drill Press & Geared Tapping Attachment |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V2, 1911, pg. 8 |

|

Insert Date: |

4/10/2020 11:49:23 AM |

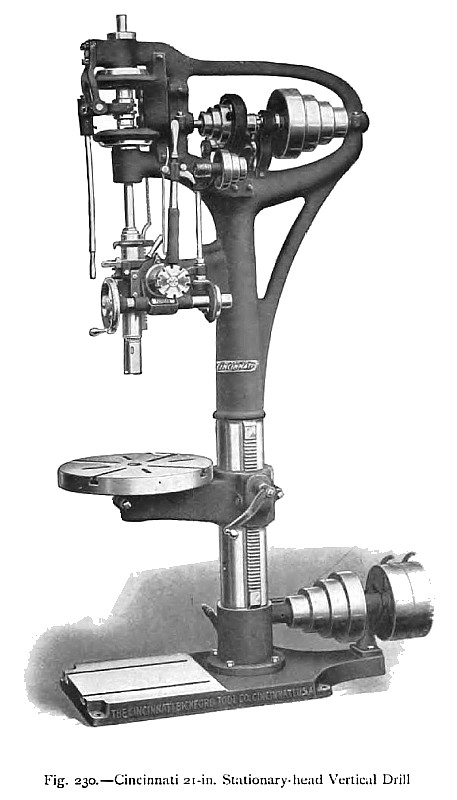

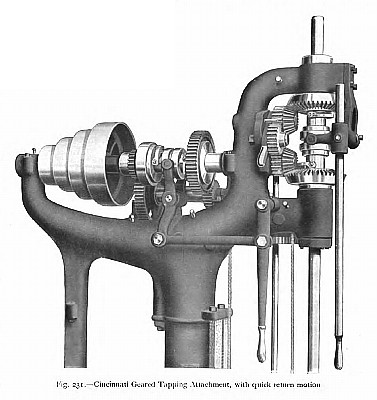

A Cincinnati machine of a type similar to the large one above described, but with a stationary head, is illustrated in fig. 230. Instead of driving the spindle feed gear positively from the drill spindle, the simpler but less powerful method is adopted of driving the feed gear through the belt cone pulleys, shown at the head of the column, and through a worm gear. It will be seen that the motion of the drilling spindle may be reversed by suitably operating the pair of bevel wheels which drive the spindle, and that the machine is fitted with the Cincinnati geared tapping attachment, which can be completely disengaged when no tapping is to be done. Fig. 231 is an enlarged view with all guards removed, showing the details of the tapping mechanism as fitted to a machine of a different construction. The lower spindle bevel is driven directly from the pinion bevel on the driving shaft; while the upper bevel is driven in the reverse direction, and at a considerably greater speed, through the gearing, shown in the illustrations, the intermediate wheel being introduced to reverse the motion of the upper bevel. It will be seen that the intermediate wheel can be swung out of mesh with the positive-geared feed driving spur wheel, by moving upwards the small lever at the left side, when it is desired to disengage the tapping gear, which then remains idle and is not subjected to wear. By a forward movement of the controlling lever at the front of the machine (fig. 230), the spindle is started; and, when the tap has reached the required depth, the motion of the spindle is reversed by a movement of the lever in the opposite direction, and the tap returns at a greatly increased speed.

A Cincinnati Drilling Machine with Sliding Head—Fig. 232 is an illustration of a 21-in. Cincinnati drill, fitted with a sliding head, friction back gear, patent positive-geared feed, and an automatic stop and quick-return motion. A separate view of the sliding head, showing the arrangement of the positive- geared feed and the quick-change feed-box, is illustrated in fig. 233, this device being generally fitted to machines of 21 in. and heavier sizes. Six spindle feeds are obtained by suitably operating the handle of the feed-box, conveniently situated on the sliding head, and an index attached to the handle clearly registers the feed in thousandths of an inch per spindle revolution. With this positive arrangement no feed-belt is used, and to change the feed the operator is not obliged to reach to the top of the machine. On the 24-in. machine, feeds of from 6 to 39 thousandths of an inch per revolution are obtainable: a range sufficiently wide for all drilling, boring, and reaming operations within the capacity of the machine. The same illustration shows the graduation of the spindle sleeve and the automatic trip gear, by means of which the feed is disengaged when the spindle has travelled to the required depth. On the sleeve there is mounted an adjustable collar, which can be set to the scale indication corresponding with the desired depth. When the drill reaches this depth the projection on the collar releases the trip-gear levers shown in the illustration and disengages the feed worm which drives the spindle sleeve. |

|

1911 Cincinnati Bickford Tool Co., 21 in. Verical Drill Press

1911 Cincinnati Bickford Tool Co., 21 in. Verical Drill Press

1911 Cincinnati Bickford Tool Co., Geared Tapping Attachment

1911 Cincinnati Bickford Tool Co., Geared Tapping Attachment

|

|