|

Title: |

1938 Article-Detroit Lubricator Co., Model A Mechanical Lubricator |

|

Source: |

Locomotive Cyclopedia of American Practice, 1938, pg. 724 |

|

Insert Date: |

10/18/2022 9:35:26 PM |

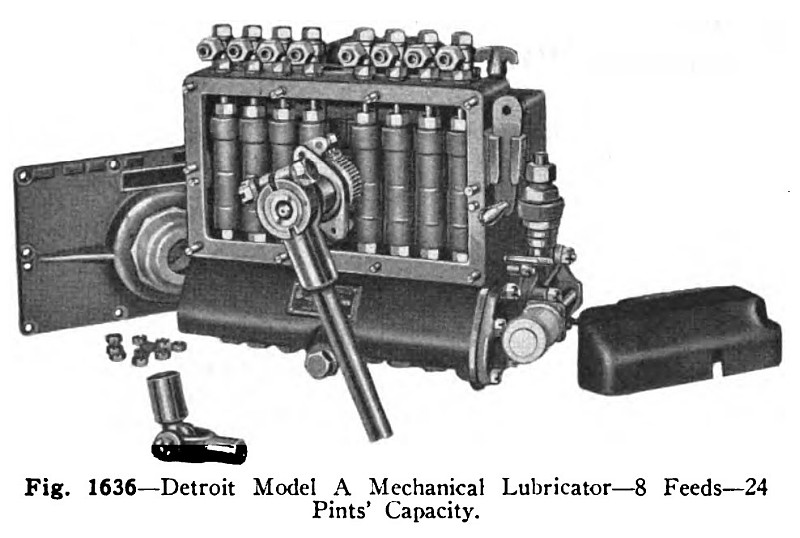

The “Genuine Detroit” Model A Locomotive Mechanical Lubricator is designed to lubricate, positively and automatically, the valves and cylinders and such other points of steam locomotives as may be desired. Being driven by a moving part of the locomotive, it starts and stops with the locomotive and increases or decreases the amount of oil delivered in accordance with the speed of the locomotive.

In its design and construction, it embodies principles, which have been thoroughly proven through several years of actual road service. It can be furnished in any number of feeds from one to eight. Each feed is a separate unit and its rate of oil delivery is individually and easily adjusted. The adjusting is done by the Mechanical Department and the feed adjustment is designed so that it may be sealed and thus made difficult to tamper with by unauthorized persons.

Built for Maximum Service at Minimum Maintenance Cost

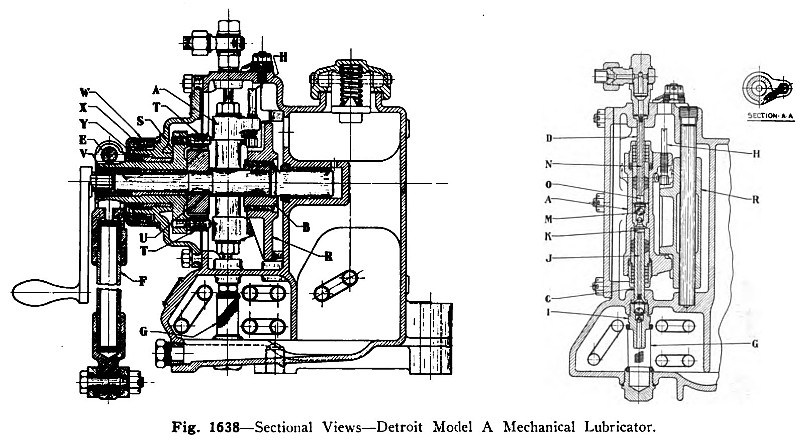

Every consideration has been given to the severe requirements of the service the Lubricator has to perform and its construction has been developed around the idea of combining the lowest possible maintenance cost with the maximum of efficiency. This result has been accomplished by making all parts unusually strong and by the liberal use of alloy steels and special long-wearing materials throughout. The hardened and ground plungers are of the double-acting packed type with ball checks, a design which is most efficient for pumping oil against high pressures and which has a very long service life. Because of the double-acting feature, there are two discharges of oil for each complete cycle of the mechanism, thus providing an even flow of oil. The plunger packing (shown in Fig. 1638) is the molded ring type, especially made for this purpose and of a design and composition which develops long service without the necessity of frequent adjustment or replacement. Heavy springs between the stuffing box nuts and packing glands ensure oiler efficiency, as by exerting a continuous pressure upon the plunger packings a tight seal is automatically maintained. They also prevent the nuts becoming loose on the headers. The operating mechanism works in a bath of oil, thus insuring positive lubrication at all times.

Accessibility of Parts

The parts of the Lubricator are easily accessible. The pumping mechanisms are in the front compartment, so when the Lubricator is drained and the protecting cover removed, the pumping mechanisms are completely exposed. The ratchet is also placed in the front of the Lubricator and thus is easily removed for adjustment. The heater and the oil strainers are individual units equally accessible and are clearly shown by the diagram—Fig. 1638 on page 724.

Sturdy Driving Arm of Fixed Length

The driving arm of the Lubricator is very sturdy and is of the non-adjustable type. It is cut to proper length at the time the Lubricator is installed. This design of arm precludes the possibility of it being tampered with or improperly changed, which is a desirable feature, as any change in the length of the arm materially affects the rate of feed. |

|

1938 Detroit Lubricator Co., Model A Mechanical Lubricator

1938 Detroit Lubricator Co., Model A Mechanical Lubricator

1938 Detroit Lubricator Co., Model A Mechanical Lubricator (Sectional View)

1938 Detroit Lubricator Co., Model A Mechanical Lubricator (Sectional View)

|

|