|

Title: |

1866 Article-L. H. Olmsted, Drill Chuck |

|

Source: |

Scientific American, V15 (New Series), 30 Jun., 1866, pg. 22 |

|

Insert Date: |

9/17/2023 12:29:15 PM |

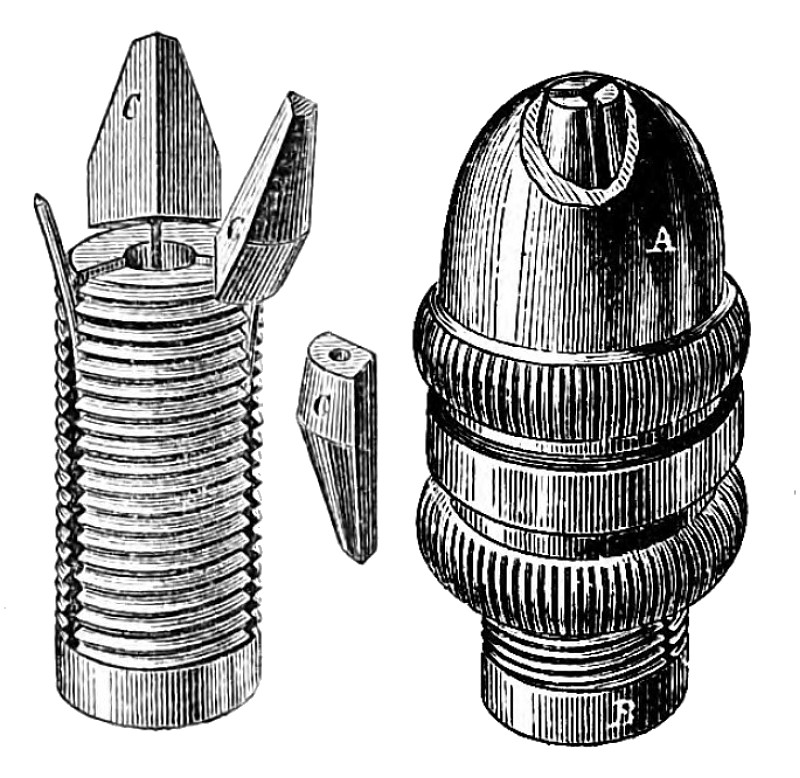

OLMSTED'S PATENT DRILL CHUCK,

We well remember the time when the "live” spindle of a lathe was provided with a tapering square hole to which the shank of the centers and each drill used was fitted. Then came the round hole, and then the drill chuck, holding the shank of the drill by a set screw or by a flatted portion fitting in a transverse slot through the chuck. The idea of a proper drill chuck, adapted to all sizes of drills and demanding only perfectly round chucks, is quite modern. Yet these chucks are considered now an absolute necessity in every well-ordered shop.

The chuck hereby illustrated seems to be a very convenient form, easily adjusted and holding the drill securely. It is also well adapted for holding wire to be threaded. Every piece of which it is composed is of cast steel well hardened. It can be furnished with a shank to fit the hole for the center, screwed on the spindle, or slipped on the center. No wrench is necessary, the gripe of the fingers being sufficient to secure the shank of any drill. The inventor claims that he has used a one-inch drill, in tenacious wrought iron in one of them, receiving a shank of only three-eighths of an inch diameter without using a wrench.

A represents the shell of the chuck with milled bosses for the fingers. The core, B, is threaded and fits on the lathe spindle or center. The front of th shell is bored to receive the jaws, C, whose outer surfaces correspond with the incline of the inside of the shell, so that in screwing up the shell, the friction of the thread acts with the compression of the two inclines of the jaws and the conformation of the interior of the shell. The core, B, is slotted to receive a steel wire spring which is inserted into the rear of each jaw, so that when relieved from pressure, the jaws open automatically.

With this brief explanation, the operation of the chuck can be easily comprehended. These chucks are made of two sizes, one with an opening of three-eights of an inch, and the other of three-sixteenths of an inch, and they can be made of larger sizes.

Patented May 15, 1866. For more particular information address L. H. Olmsted, Stamford, Conn.

US Patent: 54,760

https://www.datamp.org/patents/displayPatent.php?number=54760&typeCode=0 |

|

1866 L. H. Olmsted, Drill Chuck

1866 L. H. Olmsted, Drill Chuck

|

|