|

Title: |

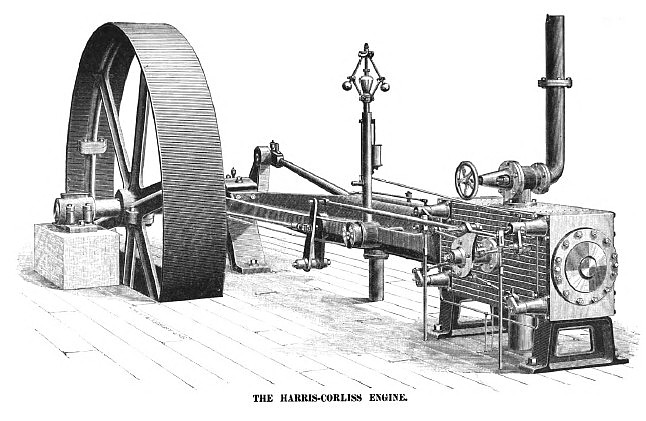

1890 Article-William A. Harris Steam Engine Co., Corliss Steam Engine |

|

Source: |

The Steam User 1890 pg 23 |

|

Insert Date: |

4/14/2011 4:19:56 PM |

The great success of the Harris-Corliss engine lies chiefly in the simplicity and precise action of the governing elements. The governor is an independent mechanism, saddled with no extraneous load, and free to instantly respond to variations in the angular velocity of rotating parts. (The slightest variation in the angular motion of the shaft or fly-wheel is immediately appreciated by the governor, and a corresponding point of cut-off is instantly indicated.) "An automatic cutoff engine is one in which the volume of steam cut off in the cylinder is exactly proportioned to the steam pressure and imposed load, to automatically regulate the speed of the engine. If the load is increased, the piston stroke to cut off is lengthened; if the steam pressure is increased, the piston stroke to cut off is shortened, and vice versa: and the regulation of cut-off for any stroke depends upon the conditions existing during that stroke. Thus each stroke of the piston and each semi-revolution of the crank possesses a perfect autonomy" In the Harris-Corliss engine, when the steam-port is opened for admission of steam to the cylinder, no obstruction exists to the free flow of steam from the boiler, and when the connecting pipe is of proper size, with few bends, and well protected from loss of heat by radiation, the initial pressure in the cylinder is within a pound or two of the pressure in the boiler. When steam flows into the cylinder, the piston advances with a velocity proportional to the load on the engine and steam pressure, the motion of the piston is communicated to the crank, and from the shaft to the governor, and a point of cut-off is indicated for that stroke, the nearness of the steam and exhaust valves to the bore of cylinder, the prompt opening and instantaneous closing of steam-valves, the rapid opening of exhaust, and the tightness of valves under pressure, all contribute to the remarkable performance of this engine. The motion of steam and exhaust valves derived from the wrist-plate is peculiar to this engine, and, next to the precise action of the regulator, has much to do with the high economy of performance. In every case where the cost of condensing water does not overbalance the gain in economy by the vacuum, a condenser and air-pump should be added, and the engine worked condensing. If (as in many instances) the condensing water can be obtained without cost, the utilization of the vacuum will reduce the cost of the power 25 to 35 per cent. In plain terms, if three pounds of coal be necessary per hour per horse-power with engine worked non-condensing, then two pounds of coal per hour will develop the same power with engine condensing. The absolute pressure of steam is measured from zero, or perfect vacuum, and consists of the pressure indicated by the steam-gauge (which is known as pressure above atmosphere), and the pressure of the atmosphere as indicated by the barometer. The latter is, for all practical purposes, a constant quantity for any given locality, and may be roughly taken at 14.5 lbs., corresponding to 29.50 inches of mercury (vacuum gauges are usually graduated to agree with the scale of barometer, and the vacuum is usually stated in inches of mercury). To the steam pressure, as indicated by the gauge, add 14.5 lbs. for total pressure; thus, if the pressure by the gauge is 60 lbs., the total pressure is 74.5 lbs.; and if the steam pressure by gauge is 70 lbs., then total pressure becomes 84.5 lbs.

By the same token, when the piston moves forward in an engine, the total pressure on steam side at any point in the stroke of piston is the pressure above the atmosphere plus 14.5 lbs.; and the total pressure for whole stroke is the mean pressure above the atmosphere plus 14.5 lbs.; thus, if the mean pressure for whole stroke is 30 lbs., the total mean pressure is 44.5 lbs., and this 44.5 lbs., whether engine is operated condensing or non-condensing, is the variable factor in estimating the load of an engine.

Now if the engine be operated non-condensing, the 14.5 lbs. (pressure of atmosphere) on steam side of piston is balanced by a like pressure of atmosphere on exhaust side of piston, and its effect is annihilated ; but if the engine be operated condensing, a large proportion of the pressure of atmosphere on exhaust side of piston is removed, and an equivalent portion of the pressure of atmosphere on steam side of piston utilized and made to do useful work. With well proportioned condensing apparatus, the pressure of atmosphere on exhaust side of piston can be reduced nearly 90 per cent. ; in other words, a vacuum in the cylinder (exhaust end) of 13 lbs. (26.5 ins.) can be maintained; and this 13 lbs. pressure per square inch of piston is an absolute gain, and should in all cases be utilized.

In a condensing engine the exhaust is connected with a tight vessel or chamber termed the condenser. (When the condensed steam is to be returned to the boiler as feed water, to the exclusion of the water used in condensing the steam, a surface condenser is used, and when the condensing water is suitable for boiler use, a jet condenser is used. Surface condensers are rarely used with laud engines, and are not equal in useful effect to jet condensers.)

When the exhaust steam enters the condenser it is intercepted by a spray of cold water which takes up the sensible and latent heat in the steam and converts it from an elastic vapor to liquid water and a partial vacuum created (a perfect vacuum is never formed in steam engine practice, neither is it desirable, for the extra economy of the perfect vacuum as compared with a partial vacuum is neutralized in effect by the extra load on the air-pump, and diminished temperature of water to the hot well). The vacuum created in the condenser extends to the exhaust end of cylinder, and the moving piston, instead of working against an atmospheric resistance of 14.5 lbs., meets a resistance of but 1.5 lbs., the remaining 13 lbs. of atmospheric resistance having been removed by the vacuum.

The air-pump worked by the engine removes the water of condensation and condensing water from the condenser, and delivers it into a hot well, from which the water is drawn to feed the boilers. The expense of engine power in working a well-proportioned air-pump is trifling, and should not be considered in the selection of condensing apparatus.

The compound engine has attracted so much attention from engineers and steam user, and its advantages over the regular condensing engine, both in economy and reduction of initial strains, are so well known, that we think it unnecessary to advance any lengthy argument in favor of their use.

The possibility of using higher steam pressures, and consequently higher grades of expansion that can be advantageously used in single cylinders, has done much toward the success of the compound engine. There is a limit, soon reached, in the expansion of steam in a single cylinder, and at this point, by the addition of one or more cylinders wherein the expansion may be continued without the excessive range of temperature which occurs in a single cylinder, resulting in internal condensation, the feasibility of the compound engine is self-evident

This company are prepared to furnish compound engines with cylinders arranged tandem, or in pairs, that is, with cylinders side by side, with sufficient space between to allow of proper arrangement of valve, gear, etc. The tandem arrangement is of less first cost, and requires less floor space.

The importance of this matter of compounding whenever high efficiency is desired cannot be over estimated. (The engines are manufactured by the Wm. A. Harris Steam-Engine Co., Providence, RI.) |

|

1890 William A. Harris Steam Engine Co., Corliss Steam Engine

1890 William A. Harris Steam Engine Co., Corliss Steam Engine

|

|