|

Title: |

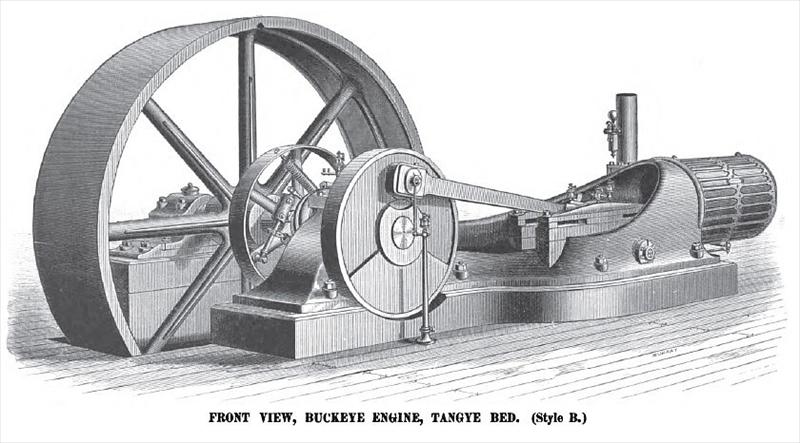

1890 Article-Buckeye Engine Co., Tangye Steam Engine |

|

Source: |

The Steam User 1890 pgs 89-93 |

|

Insert Date: |

4/20/2011 12:18:14 PM |

Style C. This was designed to combine, in the greatest possible degree, simplicity, strength, and accessibility of parts, in a design adapted to small sizes without objectionable features for medium sizes. The ratio of stroke to bore is still nearer equality than with style B, to adapt it to the high rotative speeds required for Electric Lighting and other duties requiring direct belting and high belt speed. The Slide System of style B would be troublesome to construct and keep in adjustment in small sizes, hence the simple vertical cross-head and two-slide plan of style A was adopted, but with a simple, single-piece, non-adjustable cross-head faced with genuine hard babbit-metal.

The slides being bolted to the frame, can be reset to compensate for wear, but the exceptionally large area of wearing surface and the remarkable anti-friction qualities of the metal with which the jaws are faced, renders the wear almost imperceptible; in fact, with reasonable care against dust and grit, it amounts to practically nothing. The slides have side borders and terminal cups, which retain the oil, thus still further promoting durability.

It is characteristic of the Buckeye Engine that it possesses great stability in the adjustments by which the cut-off is made to take place at the same distance from the beginning of both strokes. The variations of the point of cut-off required for regulation being effected by variations in the advance of the eccentric which moves the cut-off valve, must necessarily be equal for both strokes; hence when it is equalized for the average position, as is the practice, it will be practically equal at all other positions within any required working range. (It would be exactly so but for inequalities of the piston velocity at the ends of its travel, common to all engines using a connecting-rod, the effect of which is well understood by all engineers familiar with the mathematics of the steam-engine.) Also, the cut-off being effected by the passage of the cut-off valve over its port when at nearly the fastest part of its travel (from 2 to 5 inches, according to size), it is not sensibly affected by a degree of mis-adjustment, which would in some cases almost entirely defeat the operation of other forms of cut-off gear.

This engine contains a practical balanced slide-valve with which a riding cut-off valve can be used. All attempts to use entirely unbalanced slide-valves with riding cut-offs for automatic cut-off regulation have failed from the excessive friction and wear involved; for, as should be understood, the admission of the full boiler pressure to the valve constantly is one of the conditions necessary to perfect regulation by cut-off, and the realization of its benefits in the way of steam economy. In the common slide-valve "throttling " engine, the valve is protected from the full boiler pressure by the throttling process of regulation; hence, unbalanced slide-valves can be used on them; but when the riding cut-off is the regulating agent, it enjoys no such protection, and if such a pressure is carried, as good economy requires, and which may be easily sustained by other parts of the engine, its early destruction is inevitable.

It is to be understood, however, that they have not desired to produce, and do not claim to have produced, an absolutely balanced valve. There should be friction enough to keep the surfaces bright and prevent corrosion from starting leakage, to be afterwards increased by the cutting action of the steam, and such friction should be due to unbalanced steam pressure, for the need for it varies with the pressure. Hence, they have never sought to obtain a perfect balance, but to balance only so far as was compatible with the conditions necessary to continued tightness.

This qualification is necessary, since this necessary friction is so considerable in large engines working under high pressure, that the validity of their claim to having a "properly" balanced valve has sometimes been called in question, under the assumption that a valve to be "properly " balanced should be entirely balanced, so as to move with perfect and equal ease under all pressures.

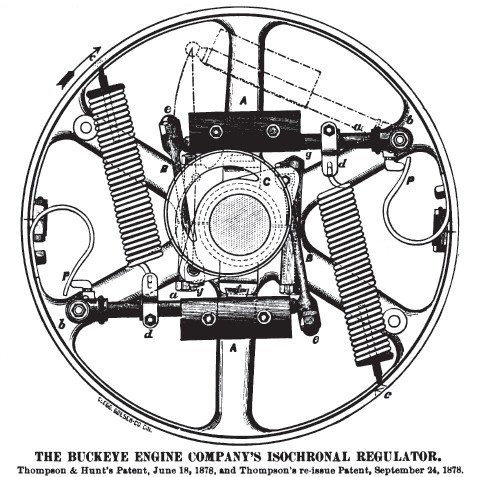

The Governor used on the Buckeye engine is virtually the pioneer in the market of the class to which it belongs (now quite numerously represented), which has come to be known as the "Shaft Governor," from its being mounted upon the shaft of the engine.

Its superiority in respect to appearance, convenience, sensitiveness, certainty of action, and, above all, safety from detachment, over all forms driven by belts or other intermediate machinery, is now almost universally recognized.

It is so simple in plan and construction, and has been so thoroughly familiarized to the public through mechanical periodicals and standard works, and through the thousands in actual successful use, that only a brief outline description here is needed.

Arms a a are pivoted to the containing wheel at b b, and connected at their other ends by links B B to ears on loose eccentric C in such a manner that their outward movement to the position indicated by the dotted lines near one of them, turns the eccentric on the shaft about one-quarter of a revolution in the direction the engine runs—that is, "advances " it. The direction of rotation is indicated by the arrows.

The arms are thrown outward by centrifugal force in opposition to the force of springs F F.

They are loaded with more or less weight at A A, according to the speed desired, the required effective weight, arm and all, being, other things equal, iu inverse proportion to the square of the revolutions in a given time.

The tension of springs F F is adjusted by screws c c. The amount of tension to be given them is determined by the amount of variation of speed due to variation of load. The more tension, the less such variation up to the point of almost absolute isochronism under favorable load conditions, beyond which unsteadiness of equilibrium would result.

The auxiliary springs P P were introduced a few years ago to obtain the refined closeness of regulation required for electric lighting. For reasons that we have not space to explain, the amount of tension required to give the closest possible regulation could only be carried while the arms were in the outer half of their range of movement. In the inner half it would be in excess, causing unsteadiness. The auxiliary springs tend to throw the arm outward, but act only through the inner half of movement range, leaving contact with the fingers on which they act in mid-movement.

Their force is made such that when the proper tension is given to springs F F to give best results, when the arms are in the outer half of their movement range, they will start out on starting the engine before the normal speed is exceeded, and the regulation will be steady at all loads. (These engines are manufactured by the Buckeye Engine Co., Salem, Ohio, and by the Kensington Engine Works, Ltd, Philadelphia—sole licensees for New Jersey (south of Trenton), eastern Pennsylvania, Delaware, Maryland, and Virginia.) |

|

1890 Buckeye Engine Co., Tangye Steam Engine

1890 Buckeye Engine Co., Tangye Steam Engine

1890 Buckeye Engine Co., Steam Engine Governor

1890 Buckeye Engine Co., Steam Engine Governor

|

|