|

Title: |

1917 Article-National Lathe Co., Engine Lathes |

|

Source: |

Machinery Magazine Jul 1917 pgs 1019-1020 |

|

Insert Date: |

6/18/2011 11:37:24 AM |

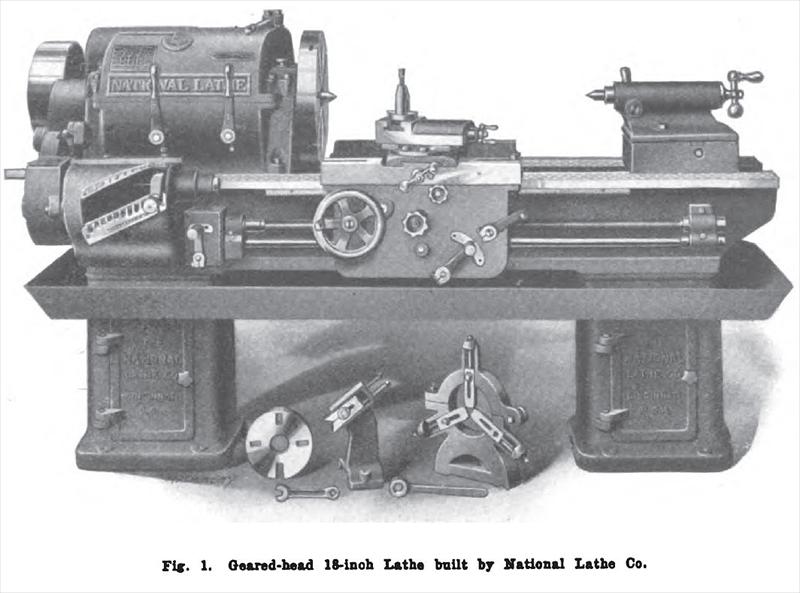

The National Lathe Co., 15 W. Second St., Cincinnati, Ohio, is now building the 18-inch geared-head lathe illustrated in Fig. 1. On the National geared-head lathe there are only twelve gears in the head. All the back-geared drive gears are five pitch and the direct geared drive gears are six pitch. All the gears are made of steel, and there are only two shafts besides the spindle. These shafts run in bronze journals in the bottom of the head. There are no journals suspended in the top of the head. This is said to insure perfect alignment and rigidity. The shafts are of 40-point carbon steel, ground to fit. The gears are cut with special cutters, giving them as perfect a mesh as possible.

The design has been worked out in such a way as to insure strength and long wearing qualities and the simplicity of the design makes it possible for the operator to change speeds with great rapidity. With a two-speed countershaft a total of sixteen speed changes are obtainable, ranging from 12 to 330 R.P.M., or eight forward and eight reverse speeds. The stopping and starting lever is conveniently located so that the operator does not have to change his position when he is checking or calibrating a piece of work. When the clutch lever is shifted, all the gears in the head are stopped. It is so designed that only the gears that are working are in mesh, the gears not required to operate being thrown out of mesh. The advantages in this arrangement are obvious.

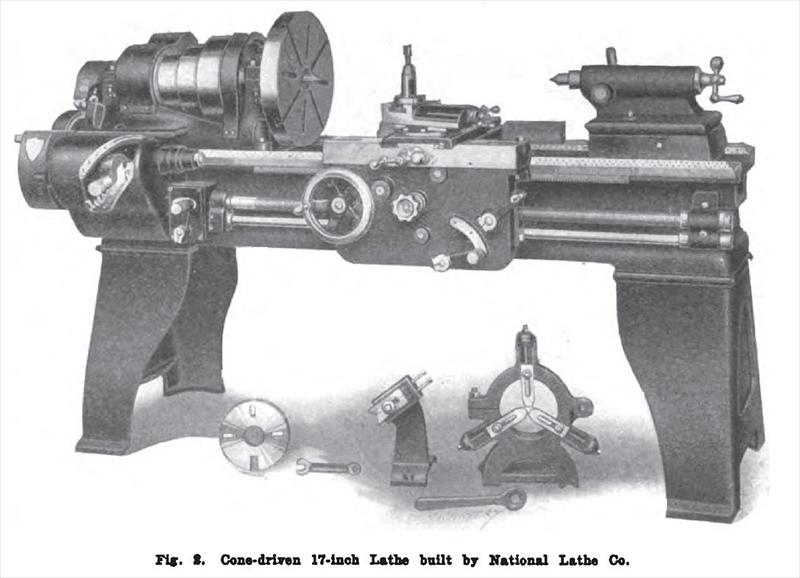

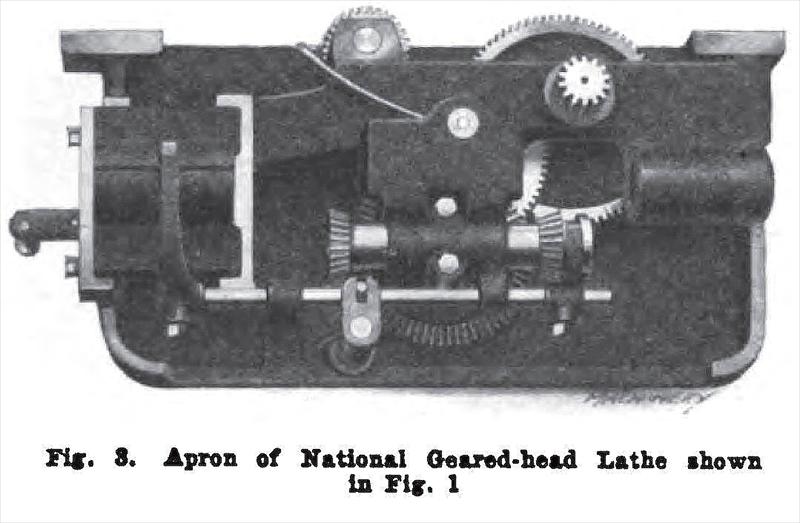

The drive is of the single-pulley type; the pulley is 12 inches in diameter, and runs at 330 R.P.M. It carries a 4-inch belt, which gives ample driving power. A friction clutch is mounted on the driving pulley shaft, and is operated instantaneously with a single lever. The countershaft clutch pulleys are 12 inches in diameter and run at 240 R.P.M. They carry a 4-inch belt. The spindle speeds range from 12 to 330 R.P.M. At no time do the gears drive at a greater speed than the driving pulley, and the greatest speed reduction is 28 to 1. In Fig. 2 is shown a 17-inch engine lathe with double back gears and a three-step cone pulley, which is another recent product of the National Lathe Co. The bed of this machine is firmly braced for its entire length and designed to absorb vibration incident to heavy work. The head-stock is also ribbed. The spindle is hollow and made of a special carbon steel and finished by grinding. The centers are No. 4 Morse taper, and the boxes are made of phosphor-bronze, with means of compensating for wear. A |L double-walled apron is provided, so that all important shafts and studs may have a rigid outboard bearing. Control of all feeds is within convenient reach of the operator, and an interlocking device makes it impossible to engage the lead-screw and feed-rod at the same time. The screw-cutting mechanism is of the quick-change gear type, and all available feeds are obtained by the movement of one lever. Speeds from 3 to 64 per inch are available on standard lathes, and from ½ to 15 millimeters on the screw-cutting lathe. The range of available feeds is from 0.006 to 0.128 inch per spindle revolution. The lead-screw is 1 5/16 inch in diameter, and is made of special carbon lead-screw stock. It is chased by means of standard and metric master lead-screws, either metric or standard pitch screws being furnished, as desired. In chasing threads, the apron half-nuts engage at the proper point, thus guarding against error and saving time. The feed-rod is gear-driven and enables the operator to obtain a.' large range of feeds, from the coarsest to the finest. The compound rest is rigidly constructed and fitted with full length taper gibs having end adjusting screws. The swivel is made completely circular, is graduated in degrees, and firmly clamped to the cross-slide. A tail-stock of the National Lathe Co.'s offset type allows the compound rest to be placed parallel with the bed. The tail-stock is provided with set-over screws for taper turning operations. Provision is made for firmly locking the carriage for cross-feed work, and the carriage is gibbed to the bed at both the front and back; it has a wide bearing for the slide-rest, with a large vee at the front and back. |

|

1917 National Lathe Co., Geared Head 18 in Engine Lathe

1917 National Lathe Co., Geared Head 18 in Engine Lathe

1917 National Lathe Co., Cone Driven 17 in Engine Lathe

1917 National Lathe Co., Cone Driven 17 in Engine Lathe

1917 National Lathe Co., Engine Lathe Apron

1917 National Lathe Co., Engine Lathe Apron

|

|