|

Title: |

1895 Article-Defiance Machine Works, Spoke & Handle Wood-Turning Lathe |

|

Source: |

Modern Mechanism 1895 pgs 470-472 |

|

Insert Date: |

6/21/2011 1:12:35 PM |

|

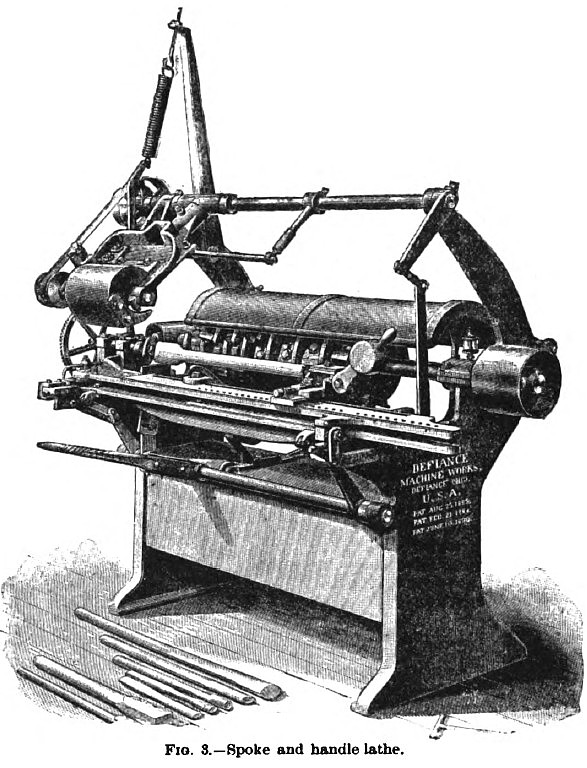

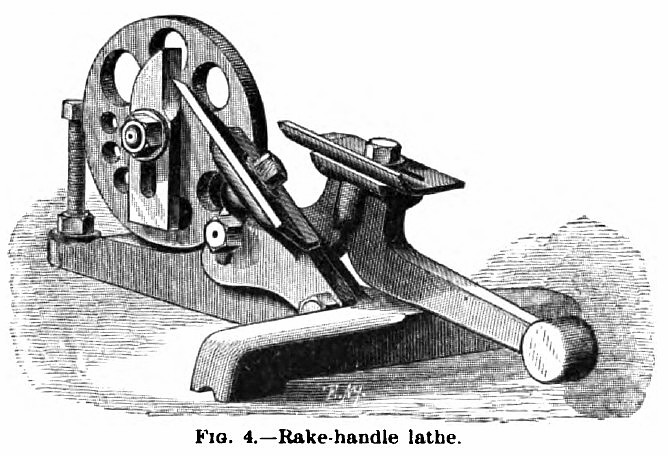

The automatic spoke and handle lathe, shown in Fig. 3., is for turning and squaring wagon and carriage spokes, although it has adjustments for turning common, Sarven, or sharp-edged shapes, making either light hickory spokes or heavy ones for wagon, truck, or artillery wheels, up to 44 in. long and 5 in. diameter There is a rotating horizontal cylinder composed of rotating knife cutter-heads placed side by side to make up the length of the spoke, each head having three cutters of 8-in. face lapping over each other so as to form a continuous cutting edge over the entire length of the cylinder. There is a table in two parts, gibbed and sliding on the frame in angular ways, being moved to and from the cutters by either a hand or a foot lever. The upper part of this table supports the turning centers, and is pivoted to the lower half near the tail center by a steel pivot, in one of several holes in the table, on which it vibrates for oval turning. At the opposite end of the head-center spindle is a cast-iron cam of the shape that it is desired to turn, this cam riding against an upright shoe extending up from the lower table, and held snug against the shoe by a coiled spring. When the table is moved toward the cylinder to where the turning is begun, an automatic feed slowly rotates the object to be shaped, and the cam rotating against the shoe oscillates the table in a path corresponding with the shape of the cam. When the pivot is placed directly opposite the tail center the machine will turn the work round at the tail end, gradually changing in section toward the other end, where it will correspond with the shape of the cam. For long, oval, or irregular turning, where both ends must correspond in section with the cam, the vibrating part of the table is locked fast with the lower part, and the cam rotates against a shoe fastened to the frame, thus vibrating both tables alike at each end. The diameter of the turning is regulated by screws. The tail-center can be adjusted at any desired distance from the spur center for short or long turning, or at right angles for straight or taper turning. The swinging cutter-head is made to advance and retreat from the work automatically, its position being regulated by the movement of the table, the section turned being governed by a cam upon the live center table. It will turn square, octagonal, or any other section desired. A desirable attachment to any ordinary wood-lathe, that is sufficiently strong for turning rake-handles and similar pieces, is a concentric slide, shown in Fig. 4. It consists essentially of a circular plate having through it a number of circular holes of graded sizes, the centers of all of them being the same distance from the center of the disk itself, which rotates on a horizontal axis. The article turned is finished to correct form by a knife on a swinging arm, which passes over a pattern fastened to the lathe-shears in front. |

|

1895 Defiance Machine Works, Spoke & Handle Wood-Turning Lathe

1895 Defiance Machine Works, Spoke & Handle Wood-Turning Lathe

1895 Defiance Machine Works, Rake Handle Wood-Turning Lathe

1895 Defiance Machine Works, Rake Handle Wood-Turning Lathe

|

|