|

Title: |

1895 Article-Wais & Roos Punch & Shear Co., Combined Tin Plate Shear & Doubler |

|

Source: |

Chicago Journal of Commerce, 14 Mar 1895, pg. 11 |

|

Insert Date: |

11/6/2012 7:41:51 PM |

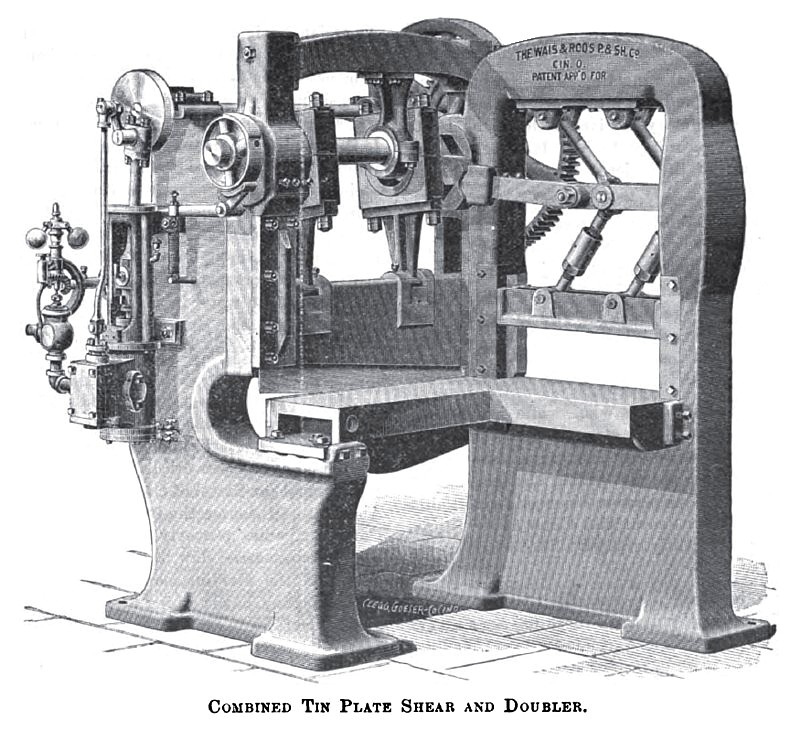

COMBINED TIN PLATE SHEAR & DOUBLER

The accompanying cut represents a now combined shear and doubler with engine, built by the Wais & Ross Punch & Shear Company, Cincinnati, Ohio. The company, we understand have been at work ever since the new industry of tin plate making had become an assured fact to get up a machine that would overcome all the inconveniences of the alligator patterns which have been in vogue in Europe for so many years. An inspection of the accompanying engraving will show what a simple and compact machine has been devised. The machine is illustrated with engine attached, but if desired it may be arranged for belt power. One of the principal features in its construction is that both the shear and doubler may be operated at one time or each independent of the other. The shear is the same as the latest improved gate patterns and is adapted to cut packs and trim tin plate, the knives cutting 36 inches in width. The doubler is driven by a crank from the same shaft that operates the shear and with the connection operates the toggle joints which produce a powerful though quiet running motion. The doubler opening is 28 inches wide and the head lifts about 8 inches, made adjustable by couplings having right and left threads, so that it is exactly parallel and enabling the operator to double either tight or loose as he may desire. Other advantages to which attention is directed are that it is not necessary for the operator to change position while doubling hence he economizes time; the machine furthermore doubling very heavy metal. It is compact, takes up small space, and requires a correspondingly small foundation. There are no obstructions, such as pit, cam shaft, etc., and the engine and gearing are also entirely out of the way. The manufacturers mention that the machine is made of the best material throughout, the table and working parts are adjustable and the engine, which is also adjustable, is 7x10 inches. When complete for shipment the machine is mounted on heavy oak skid with pipe connections all in place ready to turn on the steam, the weight being about 5400 pounds. |

|

1895 Wais & Roos Punch & Shear Co., Combined Tin Plate Shear & Doubler

1895 Wais & Roos Punch & Shear Co., Combined Tin Plate Shear & Doubler

|

|