|

Title: |

1899 Ad-John Lang & Sons, Gap-Bed Engine Lathe |

|

Source: |

Engineering Magazine, 06 Jan 1899, pg. 76 & English & American Lathes, 1900 pg 68 |

|

Insert Date: |

12/15/2012 10:41:24 PM |

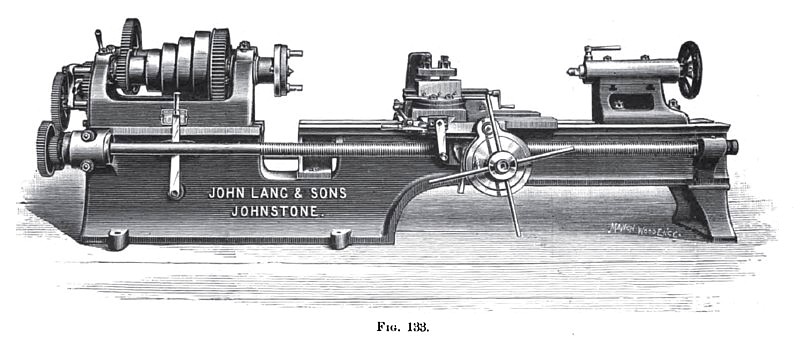

Fig. 133, p. 68, illustrates a 12-in. centre lathe to which Lang's feed is applied. In the smaller lathes, the feed-wheels are arranged in front under the headstock. Table V., in Appendix, gives these feeds. Fig. 134 is a 15-in. centre lathe by the same firm, in which the bed is of the sliding type, and in which the opening at its widest will take in 36 inches from front of chuck, with a diameter of 73 inches. The bed is slid along by a screw. All Lang's standard surfacing and screw-cutting lathes have friction-discs in the slide-rest for putting the feeds into operation. The arrangement is different from that adopted in America, but the principle is the same, and it is a departure from English standard practice. The friction - feed is put in motion instantly by the turning of a button on the outside of the discs. The gripping-power is ample. The bed in Fig. 134 is moved towards or away from the chuck by a screw. The fast headstock is treble-geared, having the cone on the spindle; the gearing is proportioned to give an equal percentage of variation at each change of speed; the cone is turned inside and balanced; the spindle is of hard crucible steel, and runs in parallel gun-metal bearings; the reversing-gear arrangement is at the end of the headstock. The loose headstock spindle has side adjustment by screw, for keeping the centres of lathe in correct alignment, and for taper turning; and has a small oil holder and pin for oiling the centre. The saddle has quick hand traverse by rack and pinion; the leading-screw has a divided nut gripping the screw on top and bottom. The compound slide-rest has a swivel arrangement for conical turning. All the wheels, including internal wheel, change-wheels, and rack, have teeth machine-cut from the solid. The lathe is self-acting, sliding, and surfacing by back-shaft, having Lang's feed motion. There are three feeds, viz., 1/16 in., 1/8 in., and 1/4 in. advance of tool per revolution of spindle.

The bed is 23 in. broad on the face, and 15 in. deep. The lathe can swing 73 in. diameter, at the gap, and will admit IB ft. between centres when the sliding bed is IB ft. long; the front journal is 6½ in. diameter; the cone has five speeds, each of 4¼-in. face. The ratios of gearing for the two changes are 6½- to 1, and 31 to 1 respectively. The following are the revolutions made by the lathe when the speed of countershaft is 100 revolutions per minute, viz.: 200, 140, 100, 71-4, 50-0, 322, 225, 16-1, ll-5, 80, 6-3, 4-4, 3-1, 2-2, 1-6. The fast and loose pulleys on countershaft are 24 in. diameter by 4½-in. face. |

|

1899 John Lang & Sons, Gap-Bed Engine Lathe

1899 John Lang & Sons, Gap-Bed Engine Lathe

1900 John Lang & Sons, Gap-Bed Engine Lathe

1900 John Lang & Sons, Gap-Bed Engine Lathe

|

|