|

Title: |

1872 Article-Rowley & Hermance Co., Pennell & Zimmer Dovetail & Shaping Machine |

|

Source: |

Scientific American, V 26 #7, 10 Feb 1872, pg. 94 |

|

Insert Date: |

3/7/2013 8:28:10 PM |

THE PENNELL AND ZIMMER DOVETAIL AND SHAPING MACHINE

This machine is designed to supply a want long felt by all sash makers.

The formation of the dovetail mortises on the stiles, and tenons on the check rails, of sash have heretofore been the most tedious and expensive parts of sash making, requiring skilled labor, and the use of at least four different machines, as well as from six to ten times handling the material to accomplish the purpose. With this improvement, the work is all done on one machine, and more perfectly than is possible by any method we have seen employed. An ordinary hand can, it is claimed, make at least ten dovetail mortises or tenons per minute, or the joints for 1,500 windows per day, being the work of some twenty skilled men.

The rapidity of production, in comparison with the old modes, is sufficient to attract attention to this machine, yet there are other advantages quite as important.

A shoulder is formed on the side of the stile, which makes a perfect fit, and a much better and stronger joint. By a slight change, which requires but a few minutes, it is made to do the work of a shaping machine for circular sash or any irregular molding, thus obviating the necessity of a separate machine for that purpose.

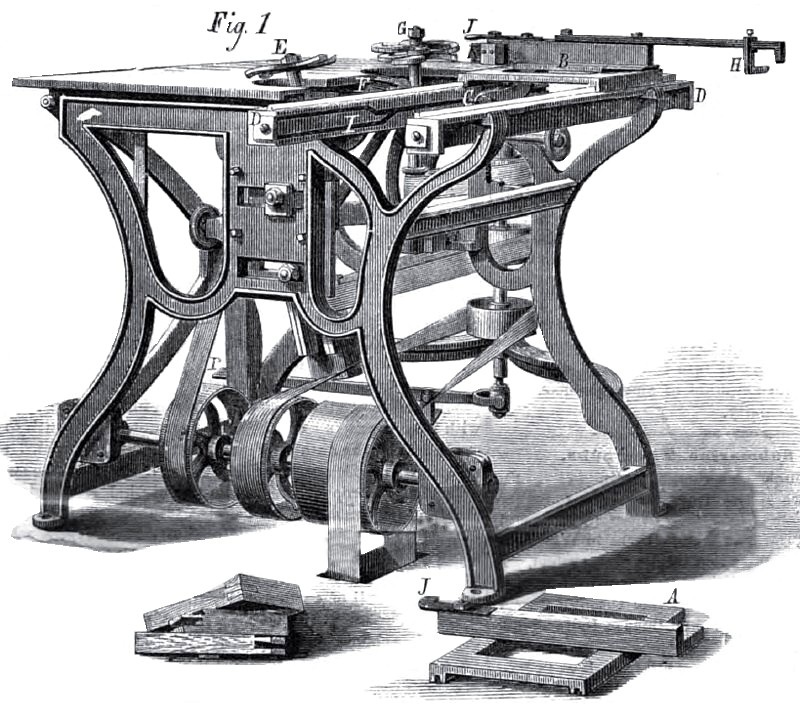

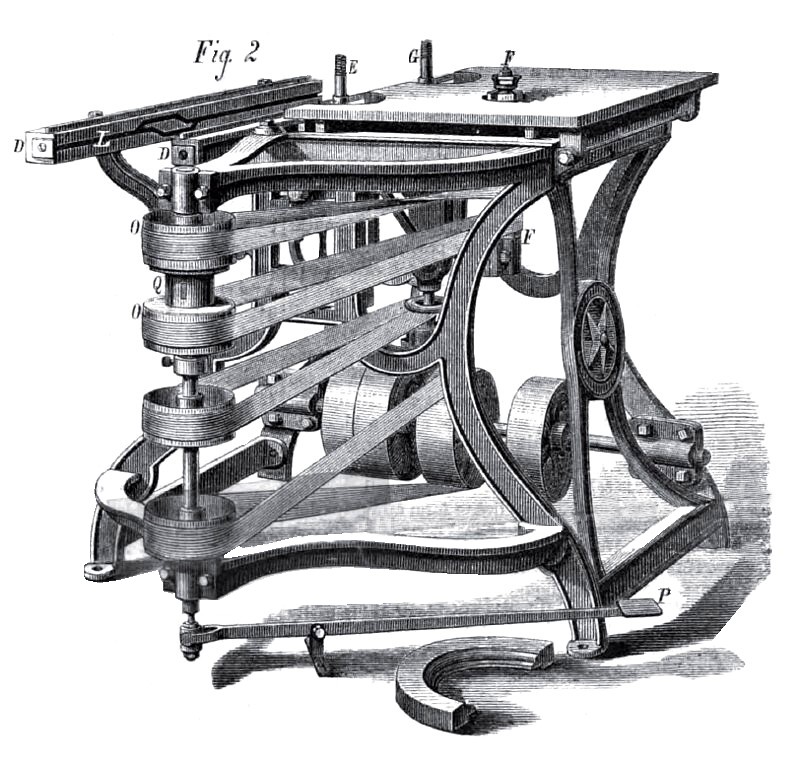

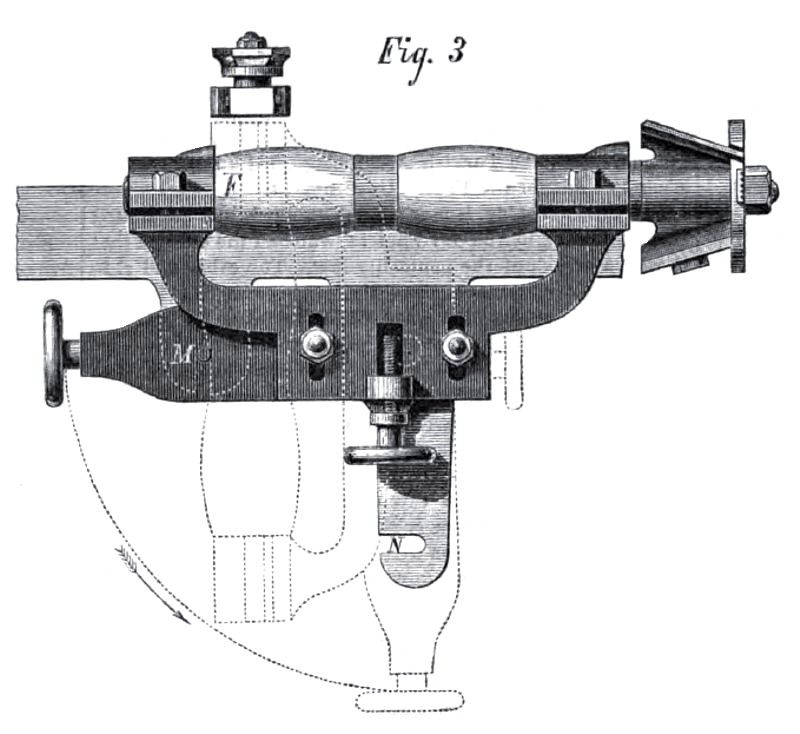

Figs. 1 and 2 are front and rear views of the machine, and Fig. 3 is a detail view, showing

the arbor, F, referred to below.

For dovetailing bottom stiles for check sash, the carriage, A, is placed on the rails, D. The arbor, E, is adjusted to the bevel desired for the dovetail. On the arbor, G, are placed two cutters, which form the straight side of the dovetail and the shoulder on the side of the stile, which is then laid on the carriage and passed through the cutters on E and G.

For top stiles, the cutters on the arbor, F, Figs, 1 and 3, are adjusted to form the shoulder on the face side of the stile. The upper cutter on the arbor G being removed, the stile is passed through as before.

For bottom, check, and common meeting rails, the carriage, B, is placed on the rails, D, (as shown in Fig. 1) with the lever pin, C, in the lower branch of the slot, I, and the arbor E is adjusted to a perpendicular position. The rail is placed between the chip-breakers, K, and passed through all the cutters. When returning, the carriage lever, C, is guided into the upper branch of the slot, I, and the rail is reversed, with the shoulder placed to the gage, H, (which gives the length desired) and the operation is repeated.

{For top check rails, the carriage, B, is reversed, and the lever pin, C, is placed in the slot, L, (Fig. 2) and operated as for bottom rails.

For shaping circular sash or irregular moldings, the bolt, M (Fig. 3), is loosened, and that end of arbor, F, is dropped to the position indicated by the dotted outline bringing the bolt, M, into the hook, N, which places the arbor in a perfectly upright position. The belts are then put on the clutch pulleys, 0, (Fig. 2) the upper belt being crossed. The motion of the arbor is reversed by a slight pressure of the foot on lever P, which connects with the clutch Q. The cutters are so constructed that the work is done equally well in either direction to cut with the grain of the wood. It is claimed that by this machine are gained the advantages of rapidity of work, the obviation of the necessity of skilled labor, perfection and strength in the joints, and the means of manufacturing check rail sash as cheaply as common sash, with uniformity of work, so that parts made and laid away for future use and easily put together at any time, and an appliance for shaping circular sash and moldings.

The machine is on exhibition at the S. A. Woods Machine Co’s. salesrooms, 91 Liberty street, New York, and 67 Sudbury street, Boston. For further particulars, address Van Gilder & Goodlauder, agents for the United States, Williamsport, Pa.

Note: This machine is shown in the Rowley & Hermance catalogues. It does not appear to have been manufactured by S. A. Woods. |

|

1872 Article-Rowley & Hermance Co., Pennell & Zimmer Dovetail & Shaping Machine (fig. 1)

1872 Article-Rowley & Hermance Co., Pennell & Zimmer Dovetail & Shaping Machine (fig. 1)

1872 Article-Rowley & Hermance Co., Pennell & Zimmer Dovetail & Shaping Machine (fig. 2)

1872 Article-Rowley & Hermance Co., Pennell & Zimmer Dovetail & Shaping Machine (fig. 2)

1872 Article-Rowley & Hermance Co., Pennell & Zimmer Dovetail & Shaping Machine (fig. 3)

1872 Article-Rowley & Hermance Co., Pennell & Zimmer Dovetail & Shaping Machine (fig. 3)

|

|