|

Title: |

1895 Article-James Spencer & Co., Four-Head Milling Machine |

|

Source: |

Engineering Magazine, V 59, 19 Apr 1895 pg. 500 |

|

Insert Date: |

11/2/2013 1:49:08 PM |

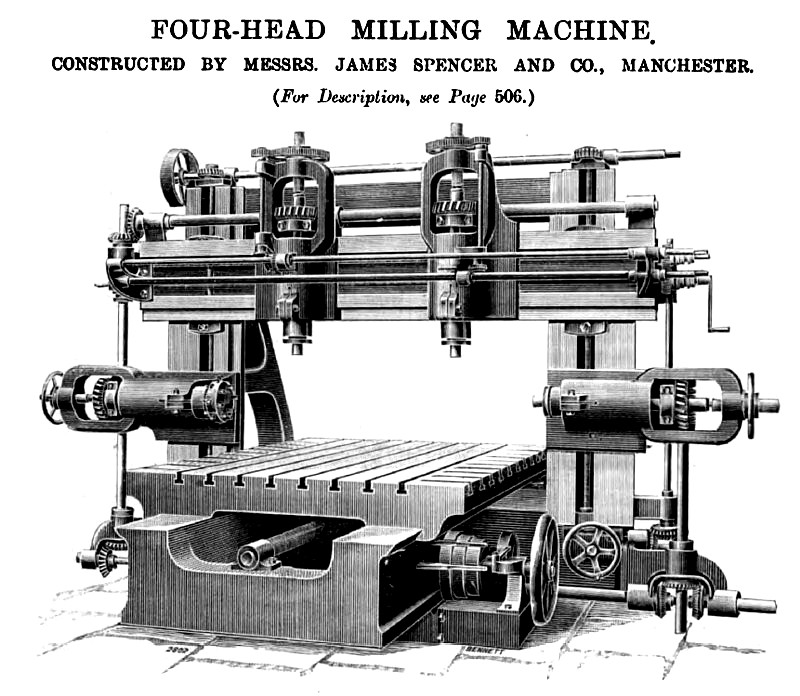

FOUR-HEAD MILLING MACHINE

The special milling machine, which we illustrate on page 500, is constructed in the form of an ordinary planing machine, but with two milling heads on the cross-slide, with vertical spindles, and one on each side upright with horizontal spindles. The machine is arranged for milling pieces 8 ft. long by 6 ft. 6 in. wide and 3 ft. in height. It comprises a strong bed 4 ft. 6 in. wide, having double box sides and fitted with a table 8 ft. long by 5 ft. 9 in. wide over all. To the sides of the bed are fixed two box uprights extending down to the floor, and securely tongued and bolted to the bed. The uprights are tied together at the top by a cast-iron cross-stay with a deep flange at each end where connected to the uprights. The cross-slide is a hollow box casting, and carries two cutter head's each driven by worm gearing with phosphor-bronze worm-wheels and cut steel worm. Each head can be traversed on the cross-slide either by hand or power. There is a variable traverse by a three-speed cone. The cross-slide can be adjusted to any height either by hand or power; it is provided with worm and wheel gear and square thread screws driven by a belt pulley on the worm-shaft. On each upright is also fitted a cutter head with a horizontal spindle driven by worm gearing similar to the foregoing. The horizontal spindles are adjusted by hand only in vertical and horizontal direction?, the horizontal adjustment having a range of 6 in. Each vertical spindle can be adjusted vertically by hand only from the working end of the cross-slide, and each adjustment is independent. All the spindles are arranged to run in conical bearings with adjustments to take up wear, and each having an adjustable tail-pin to take the end thrust. The spindles are of steel, and run in phosphor-bronze bearings. The table is arranged to work self-acting or by hand in either direction by means of a square thread steel screw; there is a slow traverse in the forward direction against the cross-slide, and a quick-return traverse by power operated by a clutch and a hand lever. The machine is arranged to be driven by a three-speed cone pulley, each speed being 5 in. wide. The table has planed T-slots in the top, as in the ordinary planing machine, to fix work to. With the machine are included four cutter heads in forged steel, with conical shanks, each interchangeable with the four spindles and arranged to take f in. square steel cutters; the cutters are put in at an angle, so as to only require grinding on ends, and to obviate forging. |

|

1895 James Spencer & Co., Four-Head Milling Machine

1895 James Spencer & Co., Four-Head Milling Machine

|

|