|

Title: |

1871 Article-Griffith & Wedge Co., Vertical Portable Steam Engine |

|

Source: |

Scientific American, V 24 #5, 28 Jan 1871, pg. 63 |

|

Insert Date: |

3/7/2014 2:05:58 PM |

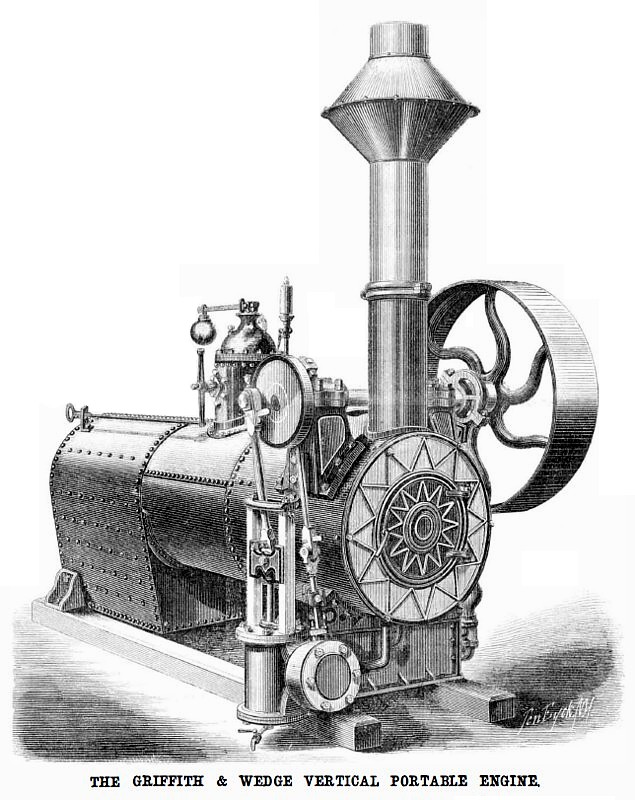

Improved Vertical Portable Engine.

This engine differs from other portable engines, in that the cylinder is placed in an upright instead of a horizontal position. The cylinder of the engine is attached to one end of a base or box, in which is placed the water heater, this box being furnished with bearings to support the front end of the boiler, directly under the tube sheet. Within this box is placed a succession of pans. The cold water being deposited on the upper pan, flows down, over the lower ones, to the bottom, by which means it becomes heated by part of the exhaust steam passing into it. This steam becomes condensed and is pumped back into the boiler. The box or base is cast with an opening at one end to admit the pans, and the open end is covered by a cap, which also forms the foot of the force pump. This force pump, which is not shown in our engraving, is furnished with ball valves, seats, and cages, of the best composition metal, and all fitted with ground joints.

The force pump is driven by an eccentric placed immediately over it on the main shaft. On the side of the eccentric is cast a small pulley, which belts on to a larger pulley attached to the boiler by means of a stud, and which carries a crank wrist from which power is transmitted to the pump; the crank pin is also made square at the end so that by the application of a crank it can be worked by hand to fill up the boiler. This pump is attached to the firebox and is open at the top. Its plunger is furnished with hemp packing, and can be repacked by an inexperienced hand, without the necessity of sending to a machine shop to have a new plunger fitted. The saddle, together with the two pillow blocks, for the main shaft to run in, as well as the smoke stack base, are all cast in one piece, which makes a strong and uniform casting. This saddle is bolted to the boiler over the tube sheet, and is connected to the lower box or base by means of a flat bar. This bar receives part of the strain between the saddle and base, and also forms the bearing for the guide yoke. The steam chest is placed in such a position on the cylinder that the valve motion is direct without the use of a rock shaft. The piston head, piston rod, cross head, wrist, and crank pin, are all made of steel, which enables lightness to be combined with strength. A weight cast at the back of the crank plate counterbalances the weight of the parts described. This enables the engine to be run at a high rate of speed with steadiness At the Cincinnati Exposition, where it was run on trial, we are informed it made 428 revolutions per minute on twenty-four pounds of steam, and took a large medal for "novelty and meritorious construction." One of the advantages claimed for this engine is the attachment of the machinery to the strongest part of the boiler, the saddle being placed immediately over the tube sheet, and the base immediately under, doing away in a great measure with the strain of the machinery through the expansion and contraction caused by the varying heat of the boiler. It will be seen that by placing the machinery below the waist of the boiler, it is not so likely to upset in transportation. The throttle is placed at the top of the steam pipe, in the steam dome, and the pipe passing through the boiler and smoke arch is protected from the cold atmosphere, thereby preventing condensation in the pipe.

Letters patent have been issued covering all the main features in the construction. Date of patent, Nov. 29, 1870.

Address for further particulars, Griffith & Wedge, manufacturers of engines, boilers, and saw-mill machinery, Zanesville, Ohio. |

|

1871 Griffith & Wedge Co., Vertical Portable Steam Engine

1871 Griffith & Wedge Co., Vertical Portable Steam Engine

|

|