Machinery Photo Index

Manufactured/Badged by:

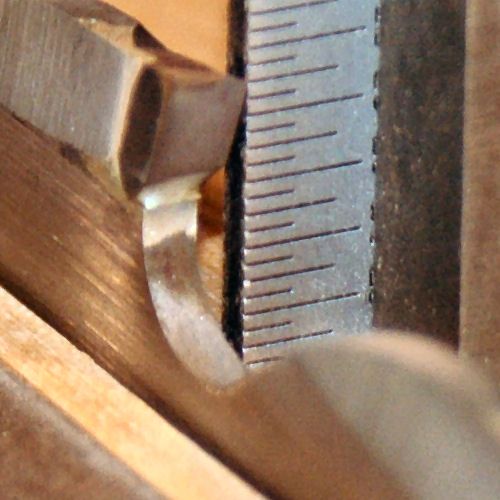

Powermatic Machine Co.

McMinnville, TN; La Vergne, TN

|

Machine Class: |

Wood Working Machinery |

|

Machine Type: |

Table Saw |

|

Machine Size: |

12"/14" |

|

Submitted By: |

George R. Hoelzeman |

|

|

Description/Model: |

Model 72 |

|

Date of Manufacturer: |

1983 |

|

Serial Number: |

8372123

|

|

Last Updated |

11/17/2016 1:14:00 PM |

|

Comments:

Source:

George Hoelzeman

|

Comments:

Source:

George Hoelzeman

|

|