|

| Illustration from article in 1919-01-23 American Machinist |

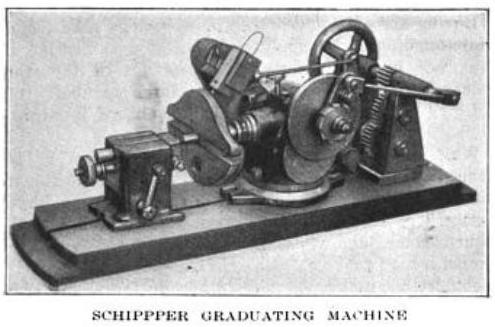

In 1913 George A. Schipper of Aurora, Indiana, applied for a patent on a gear-making machine. By 1915 he was manufacturing his "spur gear planing machine" under the George A. Schipper name. By 1918 he was operating as Schipper Machine & Tool Co., and manufacturing a range of products that included a stave jointing machine that cut fresh edges on damaged barrel staves; a dividing head; and a "graduating machine" for marking graduated dials.

In 1920 it was announced that a new firm was being established, the Langhaar Ball Bearing Co.; George Schipper was treasurer, and the new firm was taking over the factory of the Schipper Machine & Tool Co. to manufacture their ball-bearings. As well, the new firm said that it would continue the manufacture of the former Schipper company's various specialties. We have seen no ads or articles promoting the Langhaar company's manufacture of the Schipper products, and in any event the Langhaar company disappeared from the records after two or three years.

In 1929 Schipper formed a new company, G. A. Schipper Co., "to manufacture and deal in metal and woodworking machinery, apparatus, etc." The following year he applied for a patent on a machine for sanding spindles; the patent was granted in 1933. Based on very sparse evidence it appears that the G. A. Schipper Co. remained active until Schipper's death from a heart attack in 1946.

Information Sources

- September 1915 Machinery, page 75.

Spur Gear Planing Machine: George A. Schipper, Aurora, Ind. One of the noteworthy features of the design of this machine is that a roughing and a finishing cutter are carried in the same slide in such a way that the tools work alternately. The cutters are formed so that they may be ground all over after hardening. The work spindle is mounted in such a way that the maximum rigidity is obtained; and here is said to be no tendency for the tool-slide to chatter when the machine is working at high speed. This machine is particularly adapted for manufacturing, and is said to possess a high capacity for producing accurately finished spur gears.

- We learned of this maker from a 1943 booklet about manufacturers in High Point NC; the booklet provided inventories of the machinery at each factory, which in one case included a "Schipper" sander, which based on the cryptic description, was an attachment fitted to a 54" Nash sander.

- February 1919 Machinery page 568-9 has a writeup on the Schipper graduating attachment for index-centers, a follow-up to an article on the same device in the October 1918 issue.

- March 1920 The American Machine & Tool Record (volume XVII No. 3, page 77).

The Langhaar Ball Bearing Company

is the title of a newly organized concern... The incorporators are as follows: Louis Langhaar, Vice-president and General Manager; George Schipper, Treasurer, and others.

The new company was organized primarily to manufacture the Langhaar Self-adjusting Ball Bearings under patents granted to Mr. Louis Langhaar, and incidentally will take over the entire assets, machinery and equipment of the Schipper Machine Tool Co., of Aurora, Ind., where the Adjustable Ball Bearings will be manufactured, as well as the Schipper Dividing Head and other specialties formerly manufactured by the Schipper Machine Tool Co. Cincinnati capital is back of the new enterprise.

- 1921 Engineering Directory lists "Schipper Machine & Tool Co., Aurora, Ind." in the category of Graduating Attachments.

- 1929-02-28 issue of Iron Trade Review (volume 84 page 635).

Aurora, Ind.—G. A. Schipper Co. has been incorporated with $20,000 in preferred shares and 3000 shares no par value stock to manufacture and deal in metal and woodworking machinery, apparatus, etc., by George A. Schipper.

- October 1932 The Wood-Worker (volume 51 page 36), in the section of "New and Improved Machines".

Work Spindle Unit for Turning Sanders

The accompanying cut illustrates the gearbox drive work spindle which permits the stopping feature or stationary pick-up and discharge used on the turning sanders built by the G. A. Schipper Co., Aurora, Ind.

The spindle proper is 15 1/2-in. long, 1 7/8-in. diameter, and has two housings, bored to retain ball bearings, over 3-in. diameter, on which the long hollow spindle is mounted. The housings are machined accurately to fit the contour of the head-discs, which are turned circularly and provided with a T-slot to receive the solidly machined key of the housing base. The left-hand housing is provided with an extended portion to support a draw bolt lever which when in operation causes the opening and closing motion of the chucking spur drivers. The open position is held until the draw lever passes a given point on a fixed cam, when at this point a spring pressure is released and causes the spur centers or chucks to force into and grip the turning firmly. This action takes place before the dead spindle is actuated into contact with the driving belt, at which contact the spindle immediately revolves and continues to revolve until is is actuated away from the drive belt and just before the discharge station is reached and after sanding has been completed; thus the stationary pick-up and discharge.

The spindle is made hollow to admit a plunger, which in turn is backed up by a long compression spring also mounted in the hollow spindle, a draw bolt or rod running through the center of spring and extending through the rear end of spindle. The draw bolt is provided with a spool against which the draw lever acts when at the opening of pick-up station; when closed, the draw lever becomes free and does not contact the spool, which revolves with spindle only when in sanding position. The spindle, plunger, spring, draw bolt and spool all revolve as one member, while the housing and draw lever are fixed to the head discs in numbers from 4 to 8-spindle units, as desired. The importance of such spindle construction lies in the fact that since the chucking is accomplished through the center of each work spindle there is no need for tailstock carriage, slideways, operative plungers or other automatic...

...performance on high frequency. The V-belt, which is a patented drive, has the shaper-head spindle unit and the vertical ball-bearing motor supported from the same housing. This system does away with the frequency-changer, and by the use of 3-phase, 60-cycle 220 or 440-volt current it will operate the spindle at any given speed up to 10,500-r.p.m., the proportion or ratio of the sheaves governing.

- More information on Langhaar ball bearings is available in a monograph written by Louis Langhaar, Principles of Bearings, published 1922.

- 1947 issue of Iron Age, volume 159 page 17, in a listing of machine-tool trademarks: "Aurora: Valve grinders. G. A. Schipper Co., 827 State Bank Bldg., Aurora, Ind." Note that George Schipper had died in May 1946.

- Findagrave.com page on George Arthur Schipper (1888-1946).