Manufacturers Index - Buffalo Forge Co.

Buffalo Forge Co.

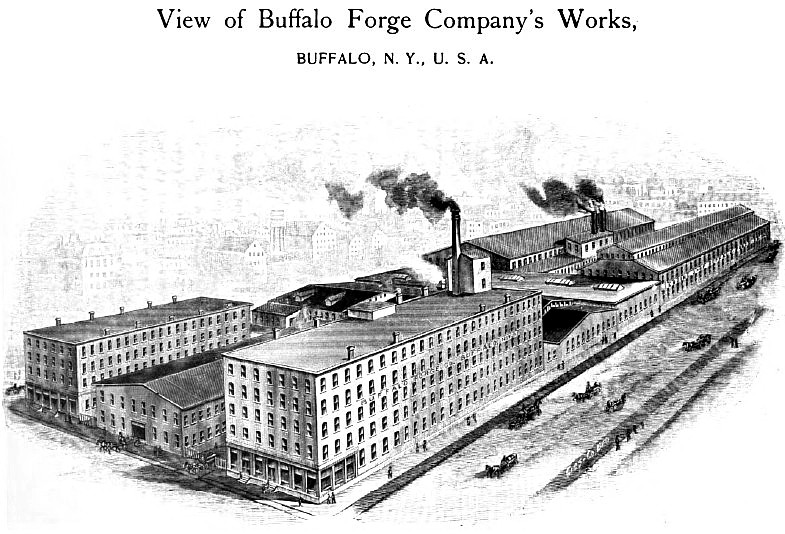

Buffalo, NY, U.S.A.

Company Website: http://www.bmt-usa.com/

Manufacturer Class:

Wood Working Machinery, Metal Working Machinery & Steam and Gas Engines

Last Modified: Aug 25 2024 7:41AM by Jeff_Joslin

If you have information to add to this entry, please

contact the Site Historian.

|

Brief History

Buffalo Forge Co. was formed in 1878 by brothers William and Henry Wendt. In 1916 William sold his interest to Henry. After Henry's death in 1929, Henry's son Henry was chairman and other son Edgar was president. Edgar retired in 1958 and Henry retired in 1966.

In 1878, Buffalo Forge manufactured blacksmith’s forges. In 1883, upright drilling machines were added to the lineup, and in 1889, stationary steam engines were added. The company quickly branched into heating, air handling, air conditioning (Willis H. Carrier of Buffalo Forge designed the first practical commercial dehumidifiers and air conditioners), dust collectors, and combination woodworking machines.

In 1941 Buffalo Forge Co. was listed on the New York Stock Exchange, with the Wendt family retaining ownership of a substantial portion of the company. The company was acquired by Ampco-Pittsburgh in 1981, in what began as a hostile takeover, although the Wendt family eventually agreed to sell their shares. Then, in 1993, Ampco sold Buffalo Forge to the Howden Group P.L.C. of Scotland. One month later Howden closed the Buffalo Forge manufacturing plant, eliminating 400 jobs (this closure seems to have been aimed at the blower operations and it is unclear how the drill press business was impacted).

Buffalo Machine Tools was created in 1997 from the machine tool division of Buffalo Forge. In 1999, the Howden subsidiary containing the remainder of Buffalo Forge was renamed Howden Buffalo. In 2003 the Buffalo the former Machine Division of Buffalo Forge was spun off, becoming Buffalo Machine Tools of Niagara, Inc.; in 2009 it changed names to Buffalo Machines, Inc. In 2010 the Howden Buffalo name changed to Howden North America.

In 1903 (or 1905, depending on which source you believe) Buffalo Forge created a Canadian subsidiary, Canadian Buffalo Forge Co., Ltd. The name changed in 1915 to Canadian Blower & Forge.

Buffalo Forge Machinery

Buffalo Forge is best remembered for the 15" and 17" drill presses that were made through most of the 20th century. They also made post drills, though these had largely disappeared from the lineup by the time of World War II when rural electrification had reduced demand for hand-powered drills. Until at least the 1920s Buffalo Forge made combination woodworking machines.

Buffalo Forge also manufactured steam engines, primarily models intended for manufacturing and other large-scale commercial applications.

In the late 1800s and early 1900s, Buffalo Forge made a bandsaw. They are very uncommon. Almost all "Buffalo" bandsaws and any tablesaws, jointers, bench grinders, etc., with the Buffalo name are 1980s Taiwanese imports of poor quality. These machines are completely unrelated to Buffalo Forge and associated businesses. As offshore imports, they are also outside the scope of this web site.

Buffalo Forge made a wide range of other products not within the scope of this site, including forges, air handling equipment, and air conditioners.

New Version of the Buffalo 15" Drill Press

Buffalo's classic 15" drill press was introduced in 1937. In 1957 the design was updated. The quickest way to identify whether a drill press is of the old or new design is to look for the integrated switch box in front of the quill—if present, the drill press is from 1957 or later. Here are the major changes in the new design:

- A new sheet-metal belt guard encloses the entire top of the machine (some old drills have been retrofit with the improved guard, so the presence of the guard is not a reliable indication of a redesigned drill press). The head guard is hinged and spring-counterbalanced.

- Integral switch. The switch wiring is tucked away within the belt guard.

- The head is clamped to the column by a split bushing, which was claimed to hold more solidly than the previous head clamp, and would not score the column.

- The head casting is split so that it can be adjusted to take up wear.

- A spindle lock has been added.

- The spindle return spring is now adjustable without tools and has an anti-flyback feature to prevent it from suddenly unwinding.

- The motor bracket is hinged to make speed changes easier.

- The designs of the both bench and floor bases were streamlined to make them easier to keep clean.

- A spindle lock is now provided so that the spindle can be fixed in place for those operations that require it, such as routing or shaping.

- Larger depth-stop nuts provide easier adjustment.

- Improved head-raising device, e.g., on the 15-M manufacturing model.

Other changes occurred over the years, both before and after the 1957 update. For example, the quill knobs changed to plastic in the mid-1950s. A detailed type study would allow us to provide better manufacturing dates. If you are interested in volunteering for this effort, or have noted other changes to these drill presses, please contact us.

Parts and Service

Buffalo Machines, Inc., formerly known as Buffalo Forge Machine Tool Division is the OEM manufacturer of all "Buffalo" products to include ironworkers, drill presses in 15", 18", 22", 3B-R-P-Mster and bending rolls. Additionally, they offer all replaceable tooling with over 10,000 parts in stock.

Contact Information for Buffalo Machines, Inc.:

Phone: (716) 201-1310

Fax: (716)201-1312

Monday - Friday from 9:00 a.m. till 4:00 p.m. EST.

Other Resources

Information Sources:

- Early references to "Buffalo Forge" are to a business of that name located in Rockbridge County, Virginia. That Buffalo Forge dates from about 1820 to at least 1855, and primarily made iron bar stock. A 1994 book, Bond of Iron: Master and Slave at Buffalo Forge, by Charles B. Drew, tells the story of this business and the people who worked there, especially those who worked there in slavery.

- The 1889 book Seeger and Guernsey's Cyclopædia of the Manufactures and Products of the United States, New York lists Buffalo Forge Co. as a maker of heating furnaces; heaters; heating apparatus; heating register frames; hot blast heating apparatus; steam heating & ventilating apparatus; drying kilns; bar cutters; blacksmiths' drill presses; hand drills; blacksmiths' drills; shearing presses; power punches & shears; metal shears; high speed automatic steam engines; stationary steam engines; steam traps; air moving machinery; blast blowers; blast gates; chain pulley blowers; cupola blowers; fan blowers; forge blowers; hand blowers; hot-blast apparatus; jet blowers; mining blowers; pressure blowers; disk wheels; drying apparatus; automatic fans; disk fans; electric fans; elevator fans; exhaust fans; mechanical draft fans; seed cotton elevator fans; steam fans; suction fans; ventilator fans; wool elevating fans; forges; portable forges; hand punches; tire benders; tire upsetters; coupling links; coupling pins; emery wheel hoods; ventilators; mechanical ventilators.

- Advertisement for Canadian Buffalo Forge Co. in the 1896 Code of Building Laws and Regulations of the City of Montreal.

- From the 1909 Proceedings of the Common Council of the City of Buffalo.

That the Commissioner of Public Works be and he hereby is directed to cause the smoke nuisance maintained by the Buffalo Forge Co., at their place of business, Broadway and Mortimer streets, to be abated, and on their refusal to abate same, the Corporation Counsel be and be hereby is directed to prosecute. — Adopted.

- Canadian industry, commerce, and finance; published as a companion volume to The Journal of Commerce, 1916, by J. J. Harpell: Lists Canadian Buffalo Forge Co., Ltd., Montreal, Que., as a producer of drill presses; blacksmiths' drills; tire benders; blacksmiths' blowers; pressure blowers; refuse burners; drying apparatus; marine engines; portable engines; waterworks pumping engines; electric fans; hot air heating apparatus; humidifiers; air pumps; centrifugal pumps; electric pumps; fire pumps; hydraulic pressure pumps; steampower pumps; hand and power tire pumps; turbine pumps; punches and punch couplings; shears and shear blades; blacksmiths' tools; cooling towers; ventilators; washers.

- Listing in the June 1926 issue of Building Age and National Builder for the Buffalo Woodworker.

- 1981-01-21 New York Times.

BUFFALO, Jan. 20—The Buffalo Forge Company, a 103-year-old concern still largely controlled by the founding family, is fighting off its second unwelcome takeover attempt in two years, arguing heatedly that the company is worth more than the offering price.

In 1979, when the H.K. Porter Company, a metal products concern controlled by Thomas Mellon Evans, acquired a big block of stock, Buffalo Forge bought the shares back for about $4 million.

Now the price tag has gone up to $53.5 million for all of Buffalo Forge's shares, which are sought by the Ampco-Pittsburgh Corporation. This time Buffalo Forge is trying a different tactic: a court fight that uses the argument that a merger would violate antitrust and Securities and Exchange Commission regulations.

The Ampco-Pittsburgh offer "is inadequate and not in the best interests of the company or its shareholders," said David R. Newcomb, president and chief executive officer.

Mr. Newcomb would not put a value on the company, which still has its headquarters in the brick factory building in a rundown neighborhood where blacksmith forges once were made. But Kidder, Peabody & Company Inc., which is Buffalo Forge's investment adviser, said in an S.E.C. filing that "if a decision were made to sell the entire company at this time, a price significantly in excess of $25 per share could be obtained."

'Compatible Product Lines'—Ampco already has purchased 72,400 shares, or 3.38 percent, of Buffalo Forge's 2.14 million outstanding shares of common stock. "The two companies have compatible product lines," according to George F. Faherty, an analyst with the Value Line Investment Survey, which told its clients that the Ampco offer "looks like a good deal" for Buffalo Forge stockholders.

Both companies manufacture industrial equipment. Ampco, which earned $10 million in 1979 on sales of $273 million, makes railroad cars, castings, forgings and machined metal parts; Buffalo Forge produces heavy-duty fans, blowers, industrial air-conditioners, pumps and machine tools.

Buffalo Forge stock closed today on the New York Stock Exchange at 26 1/2. It had traded at $18 before the Ampco offer was made last month. Book value, according to Ampco's offering statement, is $19.33 a share. Buffalo Forge listed its book value at the end of 1979, the most recent listing, at $18.30 a share.

Financing Obtained—Ampco, controlled by the Lewis Berkman Company and the Berkman family, which together own about 42 percent of Ampco, announced that it had signed a loan agreement with four banks for up to $75 million to finance the tender offer, thus responding to Buffalo Forge's argument that Ampco did not have financing to carry off the deal and that the Berkman family was the real bidder.

Last week, a Federal judge, John P. Curtin, ordered that the financial records of the Berkman company be turned over to Buffalo Forge.

Named for its first product, a portable blacksmith's forge equipped with a small fan, Buffalo Forge has evolved into a major manufacturer of specialized industrial fans, pumps and machine tools.

The portable fan grew into bigger fans and eventually into industrial air-conditioning equipment. The tools used to make the forges became a separate line of machine tools used to punch, bend and shape metal.

Founded in 1878—The company was founded in 1878 by two brothers, William and Henry Wendt, who ran it until 1916 when William sold his interest to Henry.

Henry died in 1929 and his sons, Henry and Edgar, ran the company together as chairman and president, respectively, until 1958, when Edgar retired. Henry Wendt remained as chairman until he retired in 1966.

The company went public in 1941, when it was listed on the New York Stock Exchange. Although only one family member, Frederick S. Pierce, sits on the board today, various Wendt family members in Buffalo and Tucson, Ariz., control 313,394 shares, or 14.6 percent of the stock, the largest block. Mr. Pierce and other officers and directors say they do not intend to tender their shares to Ampco.

Buffalo Forge, which has about 2,400 employees, operates three plants in the Buffalo area, two in Virginia, and one each in Canada and Mexico. The company's products have been used to ventilate the Lincoln Tunnel, recondition damaged ships at Pearl Harbor and clear the fog from the ice on warm nights during the Stanley Cup hockey layoffs in its home town.

Earnings up 31%—From 1968 to 1971, Buffalo Forge's earnings grew to $1.43 a share from $1.15, dipped for three years, and then bounced back to $1.78 in 1975, $1.91 in 1976 and a record $3.17 in 1977.

Earnings then dropped to $2.22 in 1978 and $2.03 in 1979 before rebounding to $2.90 a share last year, when it reported an increase of 31 percent in earnings, to $6.2 million from $4.7 million. Sales rose 15.6 percent, to $121.1 million from $104.8 million. Dividends have been paid on the common stock each year since 1934.

Despite management's refusal to sell shares now, Buffalo Forge's disclosure documents show that a Wendt family trust last fall sold 3,000 shares on the open market at the same time that Ampco was acquiring its shares. Details of the transaction were not explained further and the company will not comment on the matter.

- 1981-03-24 article in New York Times: "Ampco-Pittsburgh said today that it had acquired control of Buffalo Forge..."

- March 1984 American Bar Association Journal.

In response to a tender offer of $25 per share by the plaintiff, Ampco-Pittsburgh Corp., the board of directors of Buffalo Forge Co. began a search for more favorable offers. After some negotiations, they approved a merger proposed from Ogden Corp. calling for an even exchange of Ogden stock, then trading at $32.75, for shares of Buffalo Forge. The directors also agreed to sell Ogden 425,000 shares of Buffalo Forge treasury stock at $32.75 per share, to be paid for by a 10-year, 9 percent note in the face amount of #13,918,750, and gave Ogden a one-year option to purchase an additional 143,000 treasury shares on similar terms. A bidding war between Ampco and Ogden ensued, which Ampco won with a bid of $37.50 per share.

After the takeover, Ampco refused to recognize the Ampco agreement, contending that it resulted from a breach of the directors' fiduciary duty and constituted a manipulative device in violatino of Section 14(c) of the Williams Act, 15 U.S.C. § 78n(e). Ampco refused the tender of Ogden's 425,000 shares, refused to pay dividendss on the stock held by Ogden and denied Ogden the right to exercise its option for the purchase of additional shares. Ampco sued for rescission of the transaction and sought damages from the individual members of the Buffalo Forge board if rescission was denied.

The Second Circuit concurred with the findings of the U. S. District Court for the Western District of New York (555 F. Supp. 892) that the Buffalo Forge directors did not violate their fiduciary obligations and that the sale of the treasury stock was not a manipulative device prohibited by the act. Wriging for a three-judge panel including Judges Pierce and Wisdom, Judge Van Graafeiland said courts should not substitute their judgment of the directors, the exercise of which brought about an increase in Ampco's tender offer from $25 a share to $37.50 a share.

As for the Williams Act, the panel declared that the Sixth Circuit case of Mobil Corp. v. Marathon Oil Corp., 669 F.2d 366 (1981), on which Ampco relied, was an "unwarranted extension" of the acti, which proscribes "fraudulent, deceptive or manipulative acts or practices in connection with any tender offer." "Although Congress intended that the act should favor neither management nor takeover bidders and should give neither an undue advantage that would frustrate the exercise of an informed choice by investors, Congress's concern was more with the procedural provisions of the act than with the substantive terms of takeover bids," the court stated. It found no misleading manipulative acts in this case.

(Buffalo Forge Co. v. Ogden Corp., Sept. 23, 1983, 717 F.2d 757.)

- 1993-06-05 New York Times article: "The new owner of the Buffalo Forge Company, which makes industrial fans, is shutting down the plant's manufacturing facility, a move that will eliminate 400 jobs, company officials said yesterday. The decision came a month after Howden Group P.L.C. of Scotland bought the struggling forge from the Ampco-Pittsburgh Corporation, which had owned the factory since 1981."

- The 2002 book, American Inventors, Entrepreneurs, and Business Visionaries, by Charles W. Carey, Jr., tells the story of Willis Carrier's invention of practical commercial dehumidification and air conditioning.

- A court memorandum opinion regarding an asbestos-related lawsuit provides a brief recent history of Buffalo Forge.

Buffalo Forge Company (“Buffalo Forge I”), a New York corporation operating out of North Tonawanda, New York, was engaged in the business of manufacturing industrial pumps. (ECF No. 758 ¶¶ 10, 13.) Ampco-Pittsburgh acquired Buffalo Forge I in 1981. (Id. ¶ 15.) In 1982, Buffalo Forge I merged with a New Jersey corporation known as Aerofin Corporation (“Aerofin”). (Id. ¶ 16.) Shortly thereafter, a Delaware corporation known as the Buffalo Forge Company (“Buffalo Forge II”) assumed Buffalo Forge I’s pre-merger assets and liabilities. (Id.) Buffalo Pumps, Inc. (“Buffalo Pumps”), a Delaware subsidiary of Ampco-Pittsburgh, acquired from Buffalo Forge II the assets and liabilities of Buffalo Forge I’s Buffalo Pumps Division. Id. The company resulting from the merger of Buffalo Forge I and Aerofin merged into Air & Liquid on December 31, 2009, thereby making Air & Liquid the successor-by-merger to Buffalo Forge I.

- Thanks to Theresa Silva for providing some of the material here, such as the information on non-drill products made by Buffalo Forge. Theresa was the CEO of Buffalo Machine Tools of Niagara, Inc., and she personally provided assistance for people with older Buffalo Forge machinery. She died in 2009.

- American Steam Engine Builders: 1800-1900 by Kenneth L. Cope, 2006 page 45.

Company Locations

- 1896: Block bounded by Broadway, Mortimer, Tousey and Champlin Streets, Buffalo, NY

- 1919: Business office 490 Broadway, Buffalo, NY

- 1923: 448 Broadway, Buffalo, NY

|