Manufacturers Index - American Tool & Machine Co.

American Tool & Machine Co.

Boston, MA, U.S.A.

Manufacturer Class:

Wood Working Machinery & Metal Working Machinery

Last Modified: Mar 31 2021 10:32AM by Jeff_Joslin

If you have information to add to this entry, please

contact the Site Historian.

|

Formed in 1845 as Geo. H. Fox & Co., they produced "Fox" lathes for brass turning and turret lathes. In 1864 or '65 the name changed to American Tool & Machine Co. About 1893 the company began manufacturing Valve Milling Machines. They lasted into the 1920s.

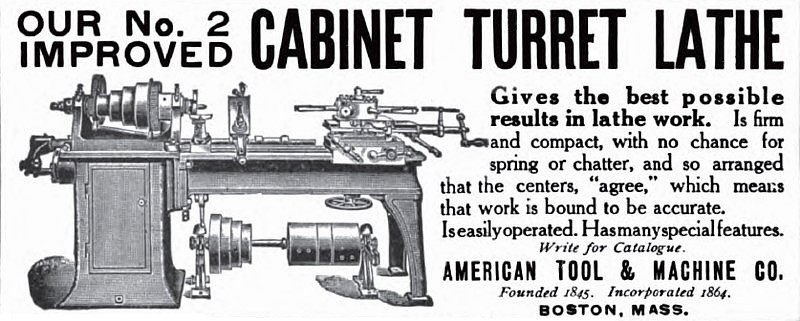

Advertisement from September 1911 Engineering Magazine

Information Sources

- The Massachusetts corporate registry database lists American Tool & Machine Co.'s first registration as 1864-10-04.

- American Lathe Builders: 1810-1910 by Kenneth L. Cope, 2001, page 2

- American Milling Machine Builders: 1820-1920 by Kenneth L. Cope, 2007 page 9

- 2013 Standard Catalog of Firearms, by Jerry Lee, 2013, provided the date when Geo. H. Fox & Co. became American Tool & Machine Co.

- From Leading Manufacturers and Merchants of the City of Boston, 1885:

The American Tool and Machinery Company, Manufacturers of Turret, Screw Chasing Hand Lathes, Chucks, and Slide Rests of all sizes, Brass Finishing Tools, Valve Milling Machines, Shafting, Hangers, and Pulleys, No. 84 Kingston Street. Benjamin F. Bradford, Superintendent.—This company was formed in 1864, with a capital stock of $100,000, the officers being George H. Fox, President, A. B. Cobb, Treasurer, and Benjamin F. Radford, Superintendent, and succeeded the firm of George H. Fox & Co., who followed F. W. Bacon & Co., who in turn succeeded Bacon & Hubbard, who founded the business in about 1850. The officers at the present time are David M. Weston, President, and Benjamin F. Radford, Treasurer and Superintendent. Mr. Weston is a native of Antrim, N. H., where he was born in 1818. He possessed to an eminent degree an inventive genius, and to him is the entire sugar interest of the world indebted for the present perfect machinery for refining, his "patent centrifugals" for purifying sugar being in use in almost every large sugar refinery, especially throughout the United States, the West India, and the Sandwich Islands. In 1850 Mr. Weston went to the Sandwich Islands and established a machine shop, remaining ten years. This sugar machine is the only one for the purpose made in this country, and is the latest, and conceded to be the best, in the world. Weston's "hydro-extractor," for drying cotton, wool, and all kinds of fabrics, for laundry, hotel or factory use, is another valuable invention of this gentleman and manufactured by this company. Another special machine built by them, and which has found its way to many of the principal leather currying establishments of the United States, the British Provinces in America, Germany, England, Scotland, France, Russia, and Australia, is the celebrated "Belt Knife" leather-splitting machine. These machines first attracted the attention of foreign leather factories about five years ago, but this company have been exporting sugar machines for twenty years. In addition to these special machines they make brass finishing lathes and tools, chucks, and slide rests of all sizes, valve milling machines, shafting, hangers and pulleys, and do repairing of all kinds.

Their principal factory is at Hyde Park, a suburb of Boston, eight miles south on the Boston and Providence and New York and New England Railroads, their works being located near and having switch connection with the former road. Here they have four brick buildings, the main machine shop being sixty-two by one hundred and forty-two feet on the ground, and three stories high, a blacksmith shop forty-two by forty-nine feet, a small machine shop fifty-two by eighty-two feet, and a large foundry, in the shape of a cross, the inside square of which is forty-eight by one hundred and twenty-three feet, with two wings, each forty-two feet square. At these works power is furnished by a seventy-horse power engine and a battery of two boilers. At their Kingston-street place, besides the general offices of the company, they have a large machine shop, the entire building, one hundred and twenty-five by sixty feet and four stories high, being occupied by them, and filled with machinery, which is driven by a fifty-horse power engine. This shop is chiefly devoted to repairing and experimenting, and also contains the patter rooms, drafting room, carpenter shop, and on the ground floor the office. This very successful house owes its success perhaps more than to any other individual to Mr. Benjamin F. Radford, who has been its superintendent since its formation. He is an inventor of fine abilities, a master mechanic of the most thorough type, and a conservative yet wise manager.

|