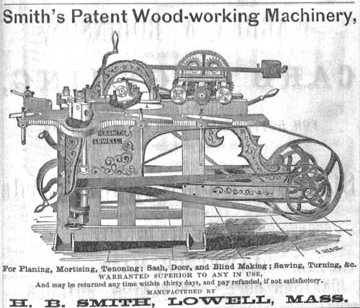

Born in 1816, Hezekiah Bradley Smith began manufacturing woodworking machinery, under the H. B. Smith banner, in the 1840s. He received his first woodworking machinery patent in 1849: a mortiser for making window blinds. His location at that time was Manchester, NH, so it is possible that his manufacturing operations were there, although we have no direct evidence of that. In any event, he moved to the Boston area shortly after receiving his patent, setting up a factory in Lowell.

In 1865, having outgrown his Lowell facilities, Smith purchased the nearly-abandoned town of Shreveville, NJ, which had been built by a cotton manufacturer that fell on hard times in the 1850s. Smith renamed the town to Smithville and moved his operations there.

H. B. Smith Machine Co. was incorporated in 1878, which may mark the first use of that name.

This company manufactured 150 different styles of machines, held over 30 patents, and at one point produced one-quarter of the nation's woodworking machinery. They produced many other products, including bicycles and tricycles.

The company was hit hard by the Great Depression, and never really recovered. It continued to operate as Smith Machine of Pennsylvania, and produced drum sanders.

Parts and Service

Smith Machine sold their assets to Machine Services Corp. of Reading, PA. That company was formed by a furniture maker, Colonial Craft Reproductions, to ensure parts and service for their H. B. Smith sander, as well as maintain such a service for other owners of H. B. Smith sanders. As of 2019 their number is disconnected but parts and service are available through Stuart Kern at 601-987-6055.

Innovations in Woodworking Machinery

Prior to 1850, North American woodworking machines had wooden frames and many other wooden parts. According to Planers, Matchers and Molders in America, H. B. Smith was the leader in replacing wood with cast iron and steel; the resulting machines were more rigid and longer-wearing.

Ad from the 1865 "Boston City Directory"

Hezekiah B. Smith patented the double-end tenoner in 1866, which represented a major advance in production woodworking.

Beginning in 1900, James Lyman Perry of Smithville was granted several patents for the first endless-belt triple drum sander; the patent was assigned to H. B. Smith Machine Co. Drum sanders became a mainstay for the company. (Perry had a history of innovation in drum sanders that dated back to 1877. He founded his own company about that time but sold it in 1880 to Porter B. Yates; that company became Berlin Machine Works and then P. B. Yates Machine Co., one of the largest woodworking machinery makers in the nation. After starting another short-lived sanding-machine company, and another, and another, Perry abandoned the entrepreneurial life and became a designer for H. B. Smith, a post he held for several years.)

Information Sources

- For more information, see the Smithville Mansion website.

- 1857 mention and 1866 ad in Scientific American. The 1857 mention is simply to "H. B. Smith".

- Ad in a 1920 issue of The Wood-Worker.

- Although we have found a number of patents granted to Hezekiah B. Smith (see the "Patents" section below), they are not entirely helpful in piecing together this history because none of H. B. Smith's patents were assigned to a company.

- Thanks to Brian Luckenbaugh of Dentech, Inc., for providing updated information on Colonial Craft Reproductions.

- Information on H. B. Smith Co. of Westfield, Massachusetts:

- The April 1882 issue of Manufacturer & Builder magazine has a full-page article, with engraving, on "The 'Union' Steam and Water Heating Apparatus", from H. B. Smith Co. of Westfield, Mass. Their New York office was at 8 Dey Street, but was moving effective 1 May to 137 Center Street.

- The April 1884 issue of Manufacturer & Builder magazine carried a note: "The H. B. Smith Company, Westfield, Mass., are having additional buildings put up, to increase their facilities and number of workmen to turn out steam-heating apparatus.

- Same magazine exactly one year later: "H. B. Smith Manufacturing Co., Westfield, Mass., contemplate building a foundry and machine shop, engine and boiler rooms, and storage quarters, this spring.

- Scribner's Magazine, June 1888, carried an ad for "Steam and hot water heating apparatus for public buildings, residences, etc." from "The H. B. Smith Co., 137 Center Street, New York, / Foundry, Westfield, Mass." The same ad also appeared in December 1888 and June 1889.

- H. B. Smith Co. of Westfield, MA, was first drawn to our attention by Michael Paxton, who has a patent vise from them.

- Thanks to vise collector and research Carl Matthews, who provided the information that H. B. Smith Co. was an unrelated business. Carl said of H. B. Smith Co., "The company is still in business. It looks like they changed their "About" page. This is what I captured last year....

In 1853, Henry B. Smith and his brother Edwin acquired a foundry situated along the canal in Westfield, Massachusetts and built a reputation for fine gray iron castings. Forward thinkers, the Smiths envisioned the day when steam, generated in a central boiler, could be piped to radiators in all rooms of a building. Working with legendary inventor John H. Mills, they created the Mills Boiler which revolutionized the way buildings were heated.

Today's Mills Boilers are a far cry from the original models, but they still embody the proven principles of boiler design that made Mr. Mills a legend. The H.B. Smith Company, Inc., continues the tradition of craftsmanship as America's oldest cast iron boiler maker. Since 1990, Mestek's Smith Cast Iron Boilers has distributed this broad line of commercial, institutional, and residential products. These boilers are a standard in the industry for longevity and efficiency.

- Thanks to correspondent Rodney Thomas for letting us know that the Machine Service Corp. number was disconnected, but that Stuart Kern is still able to provide parts at the number given above.