|

Title: |

1905 Article-Eureka Electric Miter Machine Co., Electric Miter Machine |

|

Source: |

Wood Craft, Nov 1905, pg 94 |

|

Insert Date: |

9/30/2015 8:02:35 PM |

An Electric Miter Machine

This machine is an evolution from the experiments of a practical frame maker and joiner with a thorough knowledge of the difficulties to be encountered and overcome. The old way of cutting up moldings with the hand-saw, then planing and trying the joints in an effort to make them fit in a fairly presentable way, is a tedious and unsatisfactory process at best, always disagreeable and often disappointing. It is slow, and requires much time with generally imperfect results.

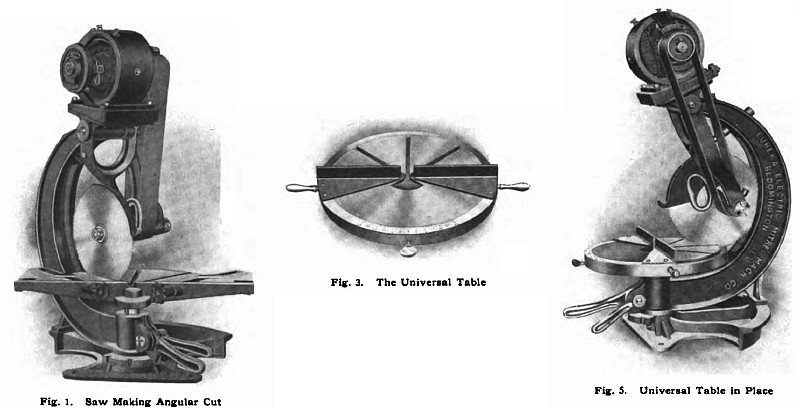

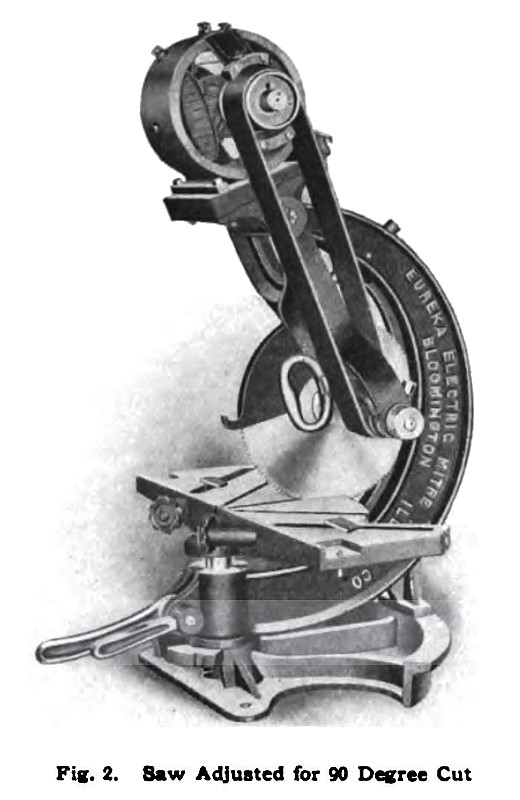

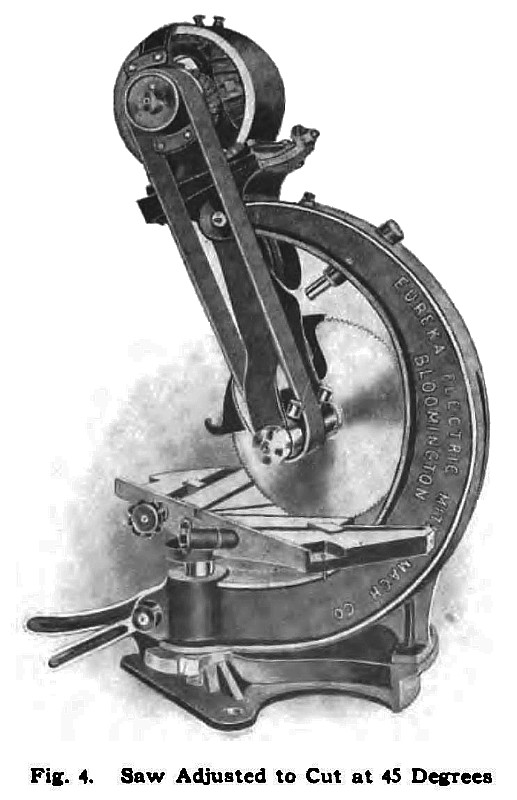

The machine is a circular saw operated by a belt-connected electric motor. The saw is attached to a swinging arm. This swinging arm and saw are suspended from the top of the supporting arch, which rotates on the hub at the base and turns from side to side to an angle of 45 degrees, so that the saw can enter the convergent slots at these angles and also at the right angle or cross cut in front.

The saw is 12 inches in diameter and hammered to a test of 5,000 revolutions. The belt is a rawhide endless, 3 inches wide. The motor is three-quarter horsepower. It is direct current and can be supplied for either no, 220 or 500 volts according to the shop current.

When the material is in position and the angle established by adjusting the arch opposite any slot in the table, the saw is brought steadily forward until the cut has been completed. The handle is released and the saw swings back into the opening in the arch, remaining there when not in use. When the arch is swung to the required position, the catch attached to the long handle in front drops into a notch and may he rigidly locked.

The machine cuts any material up to seven inches wide and five inches high. The cut is made from the top of the molding and therefore it is not cracked nor marred. It leaves edges which join like an unbroken surface. It cut Florentine and figured mouldings and all kinds of wood and composition used in frame making and finishing. The surface of the saw travels about two miles a minute, and this speed severs the grain swift and clean.

The machine, fitted with the indexed universal table, Figs. 3 and 5, is useful in any factory where wood is cut to all degrees of the circle. It will assist frame makers as well, but is especially designed for finishers. The table for the frame maker's machine is the straight style shown in Figs. I, 2, and 4. This will let the saw cut the right and left 45 degree angles and the straight cut; all that a frame maker needs. It has clamps for holding the molding firmly in place. These clamps are attached to double-threaded screws which operate them promptly. The round or universal table shown in Figs. 3 and 5, is designed to cut any angle required and is for general joinery work. A clamp is not necessary. The average workman, after using the machine a while, seldom uses the clamps on any work.

These machines are manufactured by the Eureka Electric Mitre Machine Co., Bloomington, Ill. |

|

1905 Eureka Electric Miter Machine Co., Electric Miter Machine

1905 Eureka Electric Miter Machine Co., Electric Miter Machine

1905 Eureka Electric Miter Machine Co., Electric Miter Machine (90°Cut)

1905 Eureka Electric Miter Machine Co., Electric Miter Machine (90°Cut)

1905 Eureka Electric Miter Machine Co., Electric Miter Machine (45°Cut)

1905 Eureka Electric Miter Machine Co., Electric Miter Machine (45°Cut)

|

|