|

Title: |

1906 Article-Mattison Machine Works, #6 Universal Turning & Block Machine |

|

Source: |

Wood Craft, Jan 1906, pgs. 176 & 177 |

|

Insert Date: |

10/4/2015 5:23:07 PM |

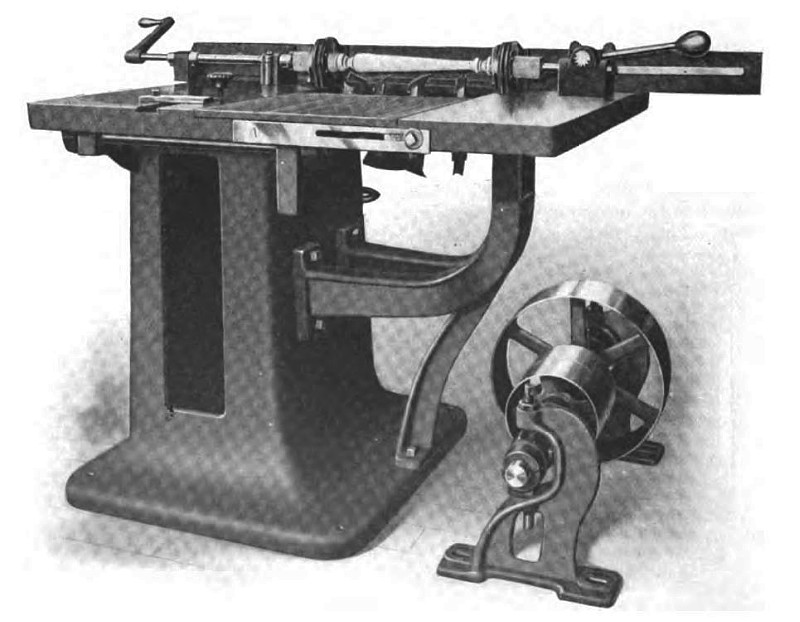

Mattison Universal Machine

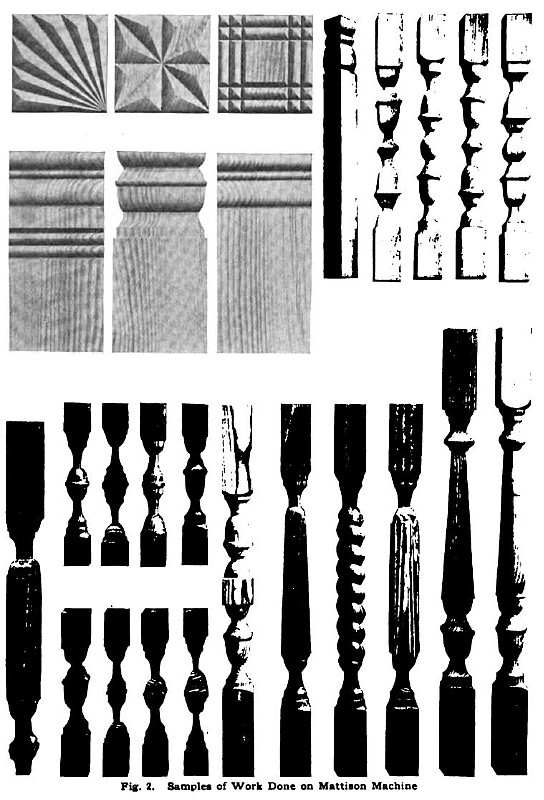

This is a combination machine for making fancy turnings, such as balusters, spindles, etc., in the round, square or octagon; also for base and head blocks, corner beads, base angles, fence pickets, fan and star corner blocks, sunrise panels, twisted moldings, and other ornamental work. It is also adapted to panel raising, making circle casings, dadoing and rabbeting, cabinet sawing, etc. The machine will turn up to 16 inches long in one operation. Where a longer turning than this is required, the stock is reversed and two cuts made on it. The largest stock that can be held in turning attachment is 3 inches square by about 34 inches in length. On square and octagon work any number of cuts can be made on any length and thickness of material. In making base blocks, square and octagon work, a cut-off saw gage is used, the work being passed over the knives the same as dadoing.

The cutter head knives act and cut in exactly the same fashion as the hand turner applies his chisel to the wood. The knives are made in sections, and the holders are right and left, holding the knife at an angle to give it a shear cut. In forming a bead, one knife begins at the highest point and shears down toward the right, leaving the opposite one to begin in the same place and shear down toward the left. No one knife cuts on more than one or two members of the pattern. The strain of cutting is very slight, from the fact that only a very small portion of the knife is in contact with the wood at any one time.

The round turning attachment is attached to the sliding gage in the table. It is a slotted iron gage on which are fitted adjustable head and tail stocks, an attachment for automatically centering the stock, and clamping chucks which grip the stock and act as steady rests. These chucks are open on the top, the work is dropped into them and then clamped. They are a great advantage on long, slim stock where there is liable to be springing and vibration; of course, not necessary and can be removed.

The table, accurately made of iron, is split, and one side of it can be adjusted in or out to make the opening larger or smaller to suit different widths of cut up to 16 inches. It is 38 inches long by 44 inches wide, when opened to its extreme width. When closed it is 36 inches width and has a 9 inch opening, It is hinged, and easily swings up for convenient access to the cutter-head. The base is cast in one piece, and is heavy and strong. The countershaft is separate from the base, and can be run either from behind the machine on the same floor, or from underneath the floor, as may be preferred. All bearings throughout machine are self-oiling. The machine is equipped with round turning attachment, self-centering attachment, clamping chucks, cut-off saw gage which can be set at any angle, ripsaw gage, saw collars, setting-up arbor, wrenches, countershaft and cutter-heads for making all the designs here shown. It is made by the C. Mattison Machine Works of Beloit, Wis., and will make profitable use of much material now reckoned as waste and fed to the fire by the mill man. |

|

1906 Mattison Machine Works, #6 Universal Turning & Block Machine

1906 Mattison Machine Works, #6 Universal Turning & Block Machine

1906 Mattison Machine Works, #6 Universal Turning & Block Machine (Work Samples)

1906 Mattison Machine Works, #6 Universal Turning & Block Machine (Work Samples)

|

|