|

Title: |

1903 Article-Luke & Spencer, Ltd., Polishing Machine |

|

Source: |

Emery Grinding Machinery, 1903, pgs. 165 & 167 |

|

Insert Date: |

11/7/2015 7:33:33 PM |

In the jewelry trades, where articles have to be cleaned, coppered, nickel-plated, silvered, gilded or bronzed, it is necessary to pass the articles through a series of polishing processes, both previous to and after they have received the deposit of copper, silver, gold or bronze, as the case may be. As these polishing operations are rather beyond the scope of the present work a very brief notice of them will suffice.

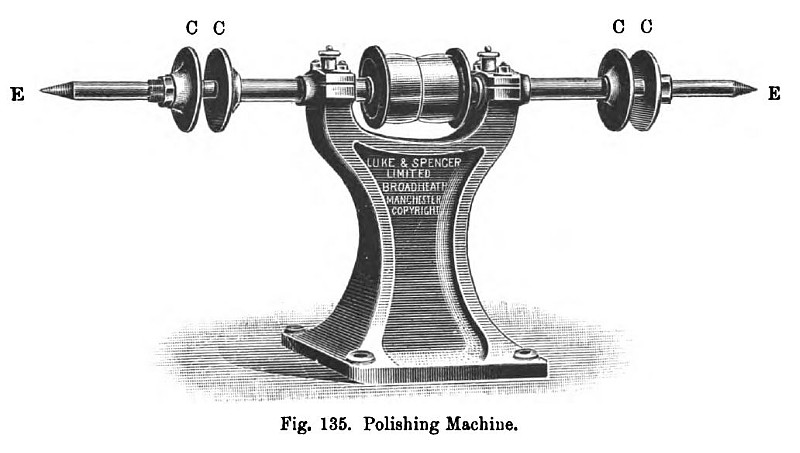

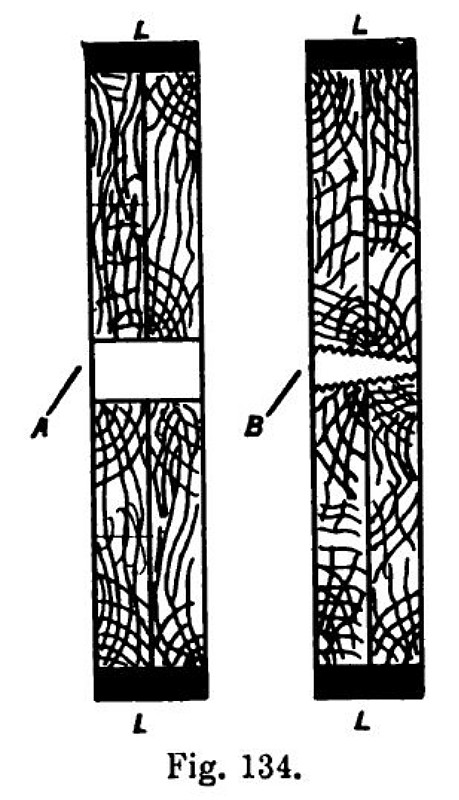

The metal articles of jewelry are cleaned by brushes, which range from the camel-hair brush to the steel-wire scratch brush; these brushes, which are made in a variety of shapes, are either used by hand or rotated upon a lathe. The articles are polished with what is known as a polishing bob, formed of a number of well-seasoned pine-wood segments glued and screwed together in cross grain section to prevent warping or splitting. When a hole has been bored in the centre, the bob is mounted upon a lathe spindle and turned circular. The hole in a bob 2 inches thick and 12 inches in diameter may have a uniform diameter of 1 inch, as in fig. 134A; or it may be taper screwed, as in fig. 134B, to allow of its being mounted upon the end of a taper-screwed polishing spindle like that in fig. 135, which represents one of Messrs. Luke & Spencer's polishing lathes or machines. It consists of a cast iron headstock, carrying a steel spindle; the bottom half of the bearing forms part of the headstock, the upper half being fixed on by two bolts to hold the spindle down. The author has known instances where the bearings of polishing headstocks have worn away very rapidly; this cannot always be avoided, but in cases where the nature of the work causes this heavy wear and tear, it is much better to have the polishing headstock constructed with bearings that may be attached to the main casting, as by this means, when a pair of bearings are worn out, a fresh pair may be introduced, thus avoiding the necessity of a new headstock, or of a new spindle of larger diameter. In the machine shown, the spindle projects well beyond the bearings, so as to allow of the work being clear of the head when operated upon. |

|

1903 Luke & Spencer, Ltd., Polishing Machine

1903 Luke & Spencer, Ltd., Polishing Machine

1903 Luke & Spencer, Ltd., Buffing & Polishing Wheels

1903 Luke & Spencer, Ltd., Buffing & Polishing Wheels

1903 Luke & Spencer, Ltd., Buffing & Polishing Wheel

1903 Luke & Spencer, Ltd., Buffing & Polishing Wheel

|

|