|

Title: |

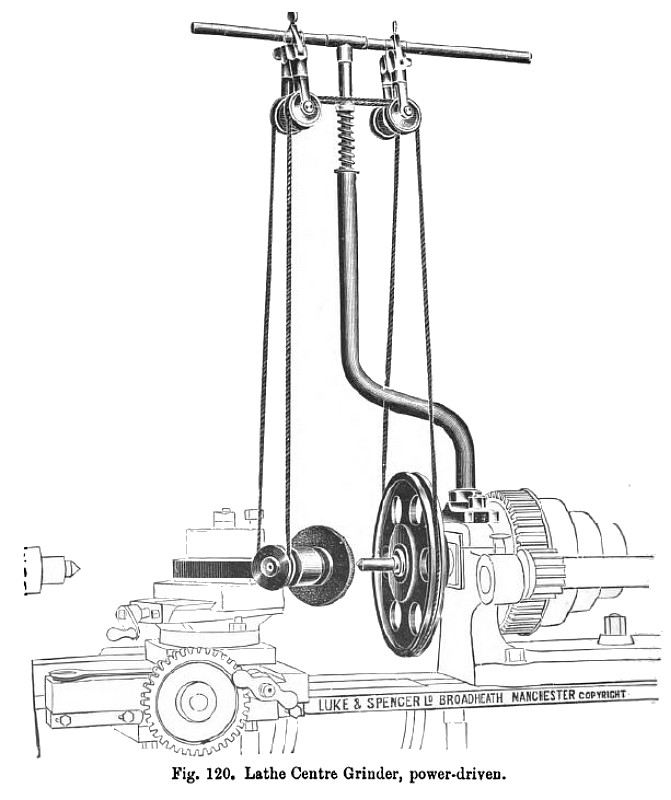

1903 Article-Luke & Spencer, Ltd., Lathe Centre Grinder (Power Driven) |

|

Source: |

Emery Grinding Machinery, 1903, pg. 148 |

|

Insert Date: |

11/7/2015 1:48:17 PM |

LATHE CENTRE GRINDER.

The old practice of correcting worn or damaged lathe centres by removing them from the headstock, softening, turning, and rehardening them, was very tedious, expensive, and unsatisfactory, owing to their liability to be warped by insufficiently careful rehardening. It has been superseded by using a grinding attachment which allows of the centre being reground without being removed. The handy portable arrangement by Messrs. Luke & Spencer, Ltd., shown in fig. 120, consists of a conical spindle with gun-metal bush, a sapphire corundum wheel 6 inches in diameter by ½ inch thick, mounted between two iron washer plates, a grooved pulley, and a holder for fixing in the slide rest tool box provided with an oil chamber to allow of constant automatic lubrication. A strong wrought iron tubular pillar (set in a suitable foot) with a spring adjustment carries a cross beam fitted with two double sets of guide pulleys. Attached to this lathe is a 12 inch grooved driving pulley, from which motion is transmitted by a twisted leather-banding rope which passes over the guide pulleys to the emery wheel spindle. The apparatus can be fixed in a few minutes. As the centres are ground true by it with a much smaller waste of material than by the old method there is great economy, especially if several lathes are made so as to allow of the application of the same driving pulley and pillar foot.

The utility and mode of using the apparatus will be evident from the following instructions.

Turn an annular groove in the lathe catch plate or face plate to fit the annular projection on the back of the grooved pulley supplied, then bolt the pulley against the face plate, having previously drilled corresponding bolt holes in the pulley and catch plate. Fix the pillar securely on the cap of front bearing of fast headstock.

Place the grinding attachment in the tool-box of the slide rest, and having brought the rest near to the centre to be ground, adjust it to the required angle; then put on the twisted leather driving band, and the apparatus will be ready for work. Take great care to keep oil from running on to the emery wheel, as this would prevent its grinding properly. |

|

1903 Luke & Spencer, Ltd., Lathe Centre Grinder (Power Driven)

1903 Luke & Spencer, Ltd., Lathe Centre Grinder (Power Driven)

|

|